Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

cross link compound:

(1) competitive price

(2) 30 years of experience

(3) stable quality

(4) customized product

Cross Link Compound:

1. Applications and cable specifications:

Used for 125°C less than 3KV locomotive cable, meeting GB/T 12528-2008. Suitable for environment with pollution of mineral oil and fuel oil.

2. Description:

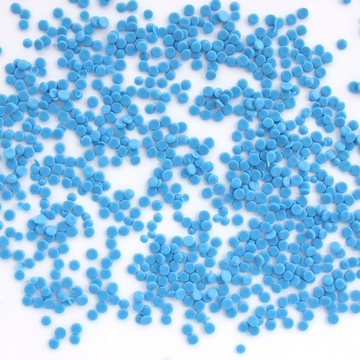

Irradiation low smoke halogen free flame retardant POE compound for locomotive cable, based on special high oil resistant POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, assistant crosslinker and other special additives.

3. Processing:

The compound can be processed with conventional extruders, and the normal PVC screw with a minimum 20:1 L/D. It is better if use low compression ratio screw.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature °C | 130 | 145 | 150 | 150 | 145 | 145 |

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Irradiated dosage:

The normal irradiated dosage(recommended) of irradiation cross-linkable low smoke halogen free flame retardant POE compound is 13 megarad.

6. Properties:

| Item | Unit | JFDW6125-G01 | JFDW1125-J01 | JDW1150-J02 | FDW6125-A01 | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | 1.44 | 1.43 | 1.34 | 1.45 | |||||

| Hardness | Shore A | 91 | 98 | 98 | 97 | ||||

| Tensile Strength | ≥Mpa | 9 | 13.7 | 10 | 15.8 | 30 | 32.6 | 17.8 | |

| Elongation at Break | ≥% | 125 | 191 | 125 | 273 | 100 | 230 | 170 | |

| Thermal Aging | Condition °C×h | 158×168 | 158×168 | 178×168 | 158×168 | ||||

| Variation on tensile strength | ≤ % | -25 | -6 | -25 | -12 | Not break | Not break | -25 | -8 |

| Elongation at Break | ≥% | 100 | 174 | 100 | 231 | 100 | 162 | ||

| Variation on Elongation | ≤ % | -40 | -9 | -40 | -15 | -40 | -5 | ||

| Thermal Prolongation: 20N/cm2 | °C×min | 200×15 | 200×15 | 200×15 | |||||

| Elongation Under Load | ≤ % | 100 | 20 | 100 | 75 | 100 | 15 | ||

| Permanent Deformation | ≤ % | 25 | 0 | 25 | 0 | 25 | 0 | ||

| Ozone Resistance | |||||||||

| Ozone density and time, Method A | ppm×h | 250-300×24×25 | 250-300×24×25 | 250-300×3 | 250-300×24×25 | ||||

| Ozone density and time, Method B | ppnm×h | 200±50×72×40 | 200±50×72×40 | 200±50×72×40 | |||||

| Surface after test | Non cracking | pass | Non cracking | pass | No fissure and not break | Non cracking | pass | ||

| Oil resistance | Oil | 20# machine oil | 20# machine oil | 902# machine oil | |||||

| Condition °C×h | 100×70 | 120×70 | 100×70 | ||||||

| Variation on Tensile Strength | ≤ % | -50 | -22 | Variation of outer diameter ≤ ±5 | ±30 | -16 | |||

| Variation on Elongation | ≤ % | -50 | -35 | Not break | ±40 | -11 | |||

| Oil resistance | Oil | 0# diesel | 0# diesel | 903# diesel | |||||

| condition °C×h | 70×168 | 70×168 | 70×168 | ||||||

| Variation on Tensile Strength | ≤ % | -55 | -38 | Variation of outer diameter ≤ ±5 | ±30 | -18 | |||

| Variation on Elongation | ≤ % | -55 | -47 | Not break | ±40 | -26 | |||

| Impact Brittleness Temperature | ≤°C | -40 | pass | -40 | pass | -60 winding | pass | -40 | pass |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1012 | 4.8×1012 | 1.0×1012 | 2.0×1013 | 1.0×1012 | 2.0×1013 | ||

| Dielectric Strength | ≥MV/m | 20 | 27 | 20 | 27 | ||||

| 150°C high temperature stress | ≤ % | 50 | 13 | ||||||

| friction resistance (round trip) | ≥ times | 1000 | pass | ||||||

| Oxygen Index | ≥ | 30 | 33 | 30 | 34 | 30 | 34 | ||

| Smoke density Flaming | ≤ | 100 | 67 | 100 | 83 | 100 | 67 | 100 | 65 |

| Non Flaming | ≤ | 200 | 164 | 200 | 185 | 200 | 164 | 200 | 196 |

| Acidity of gases evolved (PH value) | ≥ | 4.3 | 5.1 | 4.3 | 5.0 | 4.3 | 5.1 | 4.3 | 5.0 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 2.0 | 10 | 2 | 10 | 2 | 10 | 2 |

| Toxicity Index | ≤ | 5 | 2 | 5 | 2 | ||||

7. Company

- Q: The difference between resin and plastics

- Plastic refers to the resin (or in the process of using monomer polymerization) as the main ingredient, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials, but also can be said to be material with resin as the main raw material and has plasticity and product. Plastic generally refers to finished products, such as plastic cups, plastic bowls and so on.

- Q: What are the POE plastic raw materials?

- Poe plastic raw material comes from petroleum or natural gas as the raw material of petroleum chemicals. It is a kind of macromolecule resin obtained by polymerization.

- Q: What's the difference between recycled plastic bucket and plastic bucket made of raw material?

- What's the difference between recycled material and plastic bucket? Some plastic barrels are more white, and some plastic barrels feel transparent color, darker color. They say it's made of raw materials.

- Q: Raw materials for making plastic bags

- For the identification of PVC plastic bags and polyethylene plastic bags, the following simple methods are used for identification. Polyethylene film (non-toxic) film is milky white, translucent (a few stacked observation especially), feels like a lubricant is coated on the surface of a layer of wax, shaking, crisp sound, fire flammable, flame yellow, burning mucus dripping, and the candle burning smell.

- Q: What is the concept of plastic raw materials for turnover containers?

- Plastic turnover box, other features: 1) plastic turnover box outer dimension refers to the maximum size of the logistics box cover. 2) the plastic turnover box has no standard inner concave, and the case size is 18mm. 3) the carrying capacity of a plastic turnover box means that the load is uniformly placed within the range of the environmental temperature. 4) the effective working temperature of the plastic turnover box is -25 DEG C - 40 DEG C. 5) plastic turnover boxes can be stacked for storage, saving space.

- Q: Plastic raw materials packaging is generally divided into several categories?

- A variety of kraft paper, polyethylene thick film, fiber bags, aluminum foil bags

- Q: Characteristics of rigid polyurethane foam made of polyurethane raw material

- Adhesive force: strong adhesive ability, and can be firmly bonded to concrete, masonry, wood, steel, asphalt, rubber and so on;Thermal conductivity: 0.017-0.022W/m.k, lower than rock wool, glass wool, polystyrene board, extruded panels and other building insulation materials;Hydrophobic property: hydrophobic rate 95% above;

- Q: What is plastic material E-PET?

- PEI is generally broken piece of edible oil bottle, coke bottles, water bottles and other beverage bottles. Professionally speaking, PET is polyethylene terephthalate, and E-PET refers to high transparency, smooth surface, large bottle thickness, high temperature resistance at 120 degrees Celsius or more. Simply put, it's a PET bottle of good quality. Our jargon is a mineral water bottle.

- Q: ABS plastic storage conditions

- Plastic materials generally react with light and oxygen for a long time to become yellow and brittle

- Q: What are the raw materials needed for making plastic bags?

- Plastic bags, quality, food grade requirements, the use of brand new HDPE (low pressure polyethylene). Or LDPE (high pressure polyethylene). Or a mixture of the two.

Send your message to us

Irradiation Cross-linkable Low Smoke Zero Halogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches