Halogen Free FT2 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

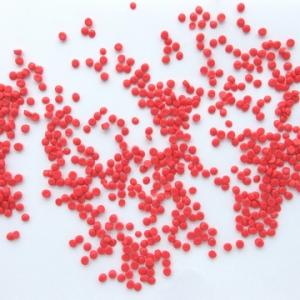

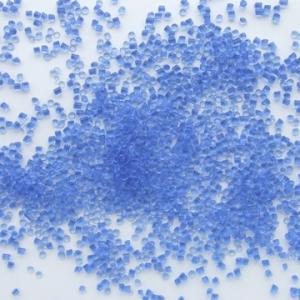

plastic granules:

FT2 flame retardant Halogen-free TPE cable compound

plastic granules: 1, Type and application: USB wires, telecommunication cables, charger wires and HDMI wires

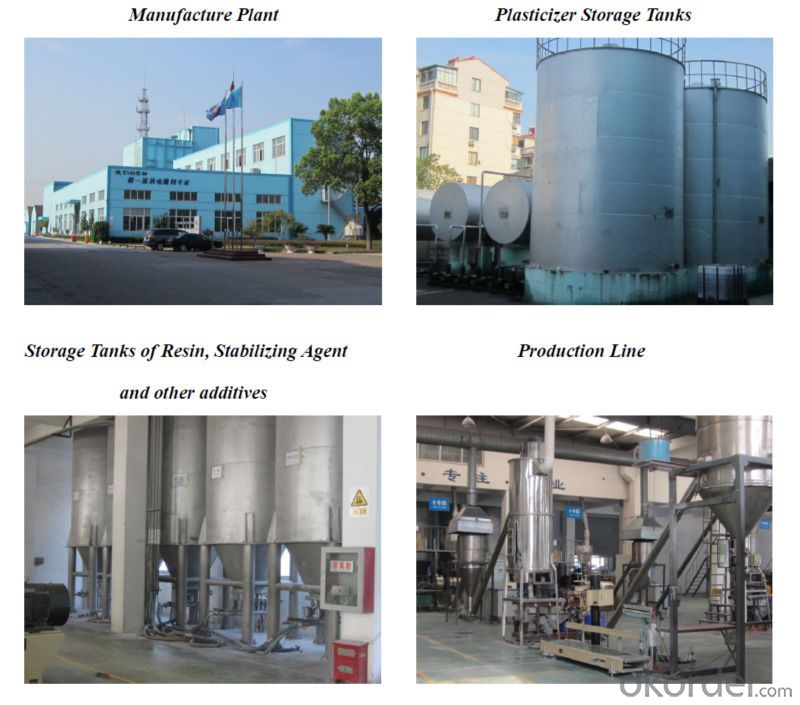

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than two months. 4, Storage and transport Packaging:20kg/bag,PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: 6,Company Pictures

|

- Q: Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- The so-called plastic raw material electroplating grade means that the particle of the plastic material is high in purity and high in polarity, and is easy to be evenly adhered to the metal particles before the plating.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- EPS is a foaming agent that is used to make foam, which is the white foam that is packed in the TV and refrigerator.

- Q: Raw materials for making plastic bags

- For the identification of PVC plastic bags and polyethylene plastic bags, the following simple methods are used for identification. Polyethylene film (non-toxic) film is milky white, translucent (a few stacked observation especially), feels like a lubricant is coated on the surface of a layer of wax, shaking, crisp sound, fire flammable, flame yellow, burning mucus dripping, and the candle burning smell.

- Q: What is the concept of plastic raw materials for turnover containers?

- Suzhou Ke Reed plastic turnover box made of polypropylene, polyethylene synthesis, light weight, long service life, safety, non-toxic, tasteless, moisture-proof, corrosion resistance, light weight, durable, can be stacked, rich color, pure etc..

- Q: PE plastic bellows raw material formula (PE and PP ratio, as well as other filling)?

- The additives are mostly organic additives, and they are usually analyzed by infrared, nuclear magnetic resonance and mass spectrometry. Fillers are mostly calcium carbonate, kaolin and other fillers, play a role in strengthening and reducing costs, and can be qualitatively and quantitatively analyzed by thermogravimetric analysis and fluorescence spectroscopy. After sample pretreatment, a single component, for unknown components need to go through a variety of instruments integrated spectrum, the final reduction formula, get the whole component analysis report.

- Q: How to make plastic raw materials?

- polyethyleneFor short, PE is a thermoplastic resin made by the polymerization of ethylene. Industrially, it also includes copolymers of ethylene with a small amount of alpha olefins. Polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature can reach -70 ~ -100 C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid), insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation properties; but polyethylene for environmental stress (chemical and mechanical function) is very sensitive, heat aging resistance difference. The properties of polyethylene vary depending on the molecular structure and density. The products of different densities (0.91 ~ 0.96g / cm3) can be obtained by different production methods. Polyethylene can be used as a general thermoplastic forming method (see plastic processing). Widely used, it is mainly used for making films, containers, pipes, monofilament, wires, cables, daily necessities, etc., and can be used as high frequency insulating materials for television, radar and so on. With the development of petrochemical industry, polyethylene production has been developed rapidly, and the output is about 1/4 of the total plastic output. In 1983, the total production capacity of polyethylene in the world was 24.65Mt, and the capacity of the equipment under construction was 3.16Mt.

- Q: Does anyone know what kind of plastic material PP-M40 is?

- High gloss PP has high gloss, high fluidity, heat resistance, medium impact toughness and fine processability. The utility model is suitable for making household appliances (rice cookers, vacuum cleaners, electric irons, etc.), office equipment, instruments and meters, beauty equipment, etc..

- Q: What are the raw materials for environmental friendly portable plastic bags?

- [environmental protection plastic bags], including recycled materials, plastic bags and new materials, plastic bags. In the process of producing plastic bags, degradable plastic bags are added to degradable plastic bags, and degradable plastic bags can be automatically decomposed after 90 days in certain conditions.

- Q: What are the raw materials for producing plastic bowls and cups?

- PP, the Chinese name is polypropylene. It is a fine kind of resin developed after nylon. It is a kind of linear polymer with high density, no side chain and high crystallinity. It has excellent comprehensive properties. Not colored, white, translucent, waxy, lighter than polyethylene. Transparency is also better than polyethylene, more rigid than polyethylene.

- Q: What are the criteria for the classification of plastic materials at injection molding and extrusion?

- In comparison, the lower melt flow rate is applicable to the extrusion grade, and the higher is applicable to the injection molding grade. As to what is low and what is high, there is a difference between the different plastic varieties.

Send your message to us

Halogen Free FT2 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords