Geomembrana Precio Colombia for Masonry and Concrete Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

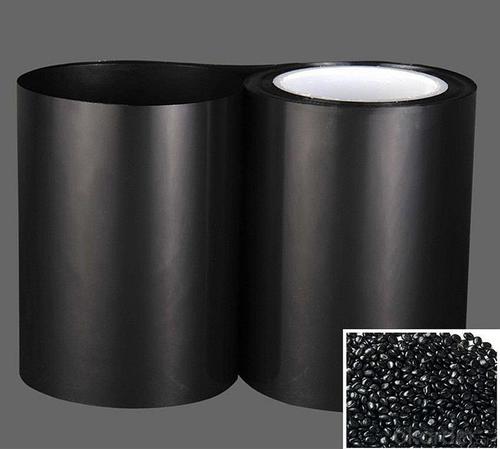

Classified by Material

1. HDPE Geomembrane

2. LDPE Geomembrane

3. LLDPE Geomembrane

Function: Waterproof

Applicable to river dams, tunnels, drainage bank seepage, metallurgy and chemical industry pollution prevention, construction, transportation, environmental protection works.

PE film thickness: 0.2mm-0.8mm Product Specifications: Width 4m-6m, weight 300g/m2-2400g/m2.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the role of geomembranes in mining tailings management?

- Geomembranes play a crucial role in mining tailings management by providing a barrier between the tailings and the environment. They are used to contain and prevent the contamination of surrounding soil and water sources by the potentially harmful substances found in the tailings. Additionally, geomembranes can help facilitate the process of tailings dewatering and consolidation, ultimately aiding in the overall management and safety of mining operations.

- Q: What are the considerations for geomembrane selection in chemical storage facilities?

- When selecting a geomembrane for chemical storage facilities, several considerations must be taken into account. Firstly, the geomembrane material should have excellent chemical resistance to ensure it can withstand exposure to the specific chemicals stored at the facility without degradation or permeation. The geomembrane should also be compatible with the containment system and any potential secondary containment requirements. Additionally, the geomembrane's mechanical properties, such as tensile strength, tear resistance, and puncture resistance, should be evaluated to ensure it can withstand potential stressors and potential damage during installation or use. The installation method and site conditions should also be considered. Some geomembranes may require specific installation techniques or site preparation, so it is important to select a geomembrane that can be easily installed and maintained in the given environment. Finally, the cost and durability of the geomembrane should be considered. A balance between cost-effectiveness and long-term performance should be achieved to ensure the selected geomembrane provides the desired level of protection for the chemical storage facility.

- Q: What should be paid attention to when installing electrothermal?film?

- The following items should be pain attention to during installation: 1, The installer should be professional. This is very important, some customers feel troublesome, so they find a electrician to install, and ultimately lead to many problems. Put aside technology, professional installation staff has many years of relevant experience after all. 2, The electrothermal?film will inevitably be abraded during transport, so electrothermal?film must conduct damage inspection experiments before laying, every loophole even of a small tip size will probably result in the subsequent fire. 3, Clean the ground which should has no sand when laying electrothermal?film, and can not step on it with shoes at the same time. 4, Look for specially trained electrician when wiring, securely connect and firmly fix each contact.

- Q: is geomembrane usually produced abroad?

- The so-called domestic produced imported geomembrane is to transfer the products to the bonded area, then resell it. Then we call it imported products. In fact, geomembrane urban construction standards in our country is no different from that of just like American Standard.

- Q: Geomembrane's features

- Width 6 meters wide composite film has high puncture-resistant strength and anti-friction coefficient, it can adapt to the ambient temperature range and has superior anti-drainage, it's applied in water?conservancy, chemical engineering, construction, transportation, iron, tunnels, waste disposal sites, etc.

- Q: What are the advantages of using geomembranes in mining operations?

- The advantages of using geomembranes in mining operations include improved environmental protection by preventing contamination of soil and water, enhanced waste management by containing and controlling hazardous materials, increased safety by reducing the risk of accidents and injuries, and cost savings through efficient storage and transportation of mining by-products. Geomembranes also provide long-term durability and stability, ensuring the integrity of mining structures and minimizing the need for maintenance or repairs.

- Q: What are the advantages of using geomembranes in agriculture?

- There are several advantages of using geomembranes in agriculture. Firstly, geomembranes help in preventing soil erosion by acting as a barrier between the soil surface and water. This is particularly beneficial in areas with steep slopes or heavy rainfall, as it helps to retain the topsoil and nutrients, ensuring better crop growth. Secondly, geomembranes can also be used for lining irrigation canals, reservoirs, and ponds, preventing water leakage and reducing water wastage. This aids in water conservation, which is crucial in regions facing water scarcity. Additionally, geomembranes act as a weed barrier, suppressing weed growth and reducing the need for herbicides, thus promoting more sustainable farming practices. Lastly, geomembranes can be used for lining manure storage facilities, preventing nutrient leaching and groundwater contamination. Overall, using geomembranes in agriculture can improve soil quality, conserve water, reduce chemical usage, and enhance overall farm productivity.

- Q: slope geomembrane sliding treatment program

- strengthen the anchoring ditch,

- Q: What are the long-term performance characteristics of geomembranes?

- The long-term performance characteristics of geomembranes depend on various factors such as the type of material used, installation techniques, environmental conditions, and maintenance practices. Generally, geomembranes are designed to have excellent durability, high tensile strength, and resistance to chemicals, ultraviolet radiation, and punctures. They are expected to maintain their integrity and functionality over a long period, typically ranging from 20 to 50 years or more, depending on the specific application and conditions. Regular inspections and proper maintenance can further extend the lifespan of geomembranes.

- Q: Can geomembranes be used in golf course pond and lake liners?

- Yes, geomembranes can be used in golf course pond and lake liners. Geomembranes are specially designed impermeable materials that can effectively prevent water seepage, making them a suitable choice for lining ponds and lakes in golf courses. They help maintain the water levels and prevent contamination, ensuring the overall health and functionality of the bodies of water in golf course settings.

Send your message to us

Geomembrana Precio Colombia for Masonry and Concrete Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords