Venta Geomembrana - Dimple Composite Geomembrane Quality Guaranteed, Low Price Promised

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

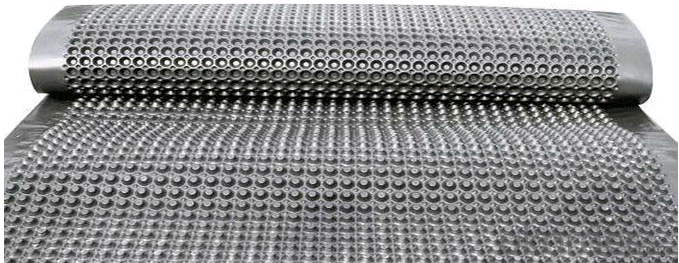

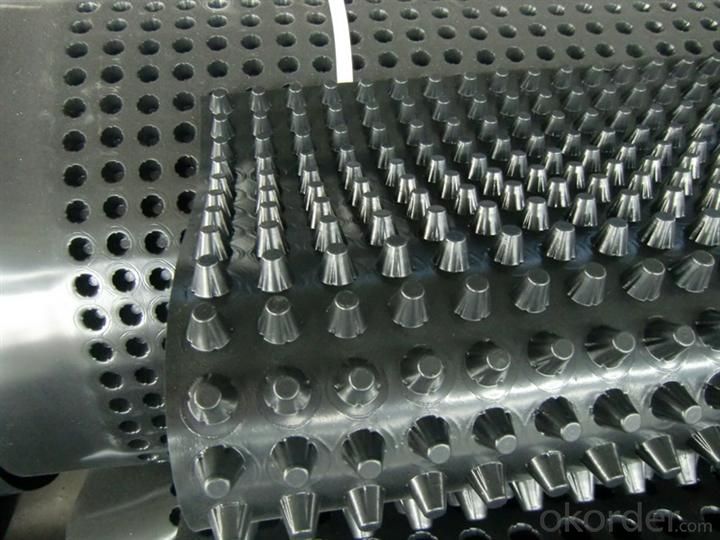

EltMembrane-CDG series of geomembrane is manufactured from High Density Polyethylene resins. Produced by extruding plastic sheet into dimple shape.These dimples,in spatial structure with certain height. Can resist long-term high pressure without deformation. On the top of the dimples, there is filtration geotextile to make sure the drainage channel ruing well without any block for any articles. For example,filling particles or concrete.

Advantages

1. strong viscosity, cold pressing sensitive

2. color white/black

3. accurate size cutting

4. custom size offered without any surcharge

Application

1, Municipal projects

2,Landfill treatment projects

3,Waste water treatment

4,Mineral waterproofing

| Composite Dimple geomembrane | |||||||

| NO. | Item Name | Technical requirements | |||||

| H10-1.0 | H20-1.0 | H10-1.5 | H20-1.5 | H10-2.0 | H20-2.0 | ||

| 1 | Tensile strength N/<5cm> ≥ | 400 | 400 | 500 | 500 | 700 | 700 |

| 2 | Elongation at break % ≥ | 200 | 200 | 300 | 300 | 400 | 400 |

| 3 | Dimensional strength Mpa ≥ | 400 | 320 | 450 | 370 | 500 | 420 |

| 4 | Dimensional stability % | ±2 | |||||

| 5 | Low tempreture impact brittle property | -35℃ crack-free bending | |||||

| 6 | Longitudinal flow capacity cm3/s( hydraulic pressure 5Kpa) | 5.6 | 8.6 | 5.6 | 8.6 | 5.6 | 8.6 |

| 7 | Longitudinal flow capacity cm3/s( hydraulic pressure 350Kpa) | 15.2 | 18.2 | 15.2 | 18.2 | 15.2 | 18.2 |

FAQ

Q: Can you accept sample order?

A: Yes, we are willing to send small samples for free, while the shipping fee should be afforded by yourself.

Q: What is your delivery time?

A: 1 days for samples, two weeks for mass production.

Q: What is your payment terms?

A: T/T , L/C, Western Union, Money Gram. 30% advance before producing, 70% payment before deliverying.

Q: How can I get my order?How can I know you sent the goods.

A: We will send you the goods by UPS, DHL, Fedex, Oversea Shipment or other forwarder,

all with tracking number or B/L.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q: How do geomembranes contribute to oil and gas containment?

- Geomembranes contribute to oil and gas containment by providing an impermeable barrier that prevents the seepage or leakage of these substances into the surrounding environment. They act as liners or covers for containment structures such as storage tanks, ponds, or landfills, ensuring that oil and gas remain safely contained and do not contaminate soil, groundwater, or nearby water bodies. Geomembranes also offer resistance against chemical degradation, UV exposure, and mechanical damage, thereby enhancing the overall integrity and longevity of oil and gas containment systems.

- Q: What is the typical thickness of a geomembrane in a pond liner application?

- The typical thickness of a geomembrane in a pond liner application can vary depending on the specific requirements of the project, but it is generally around 20 to 30 mils (0.5 to 0.75 mm) for most applications.

- Q: what's the specification of composite geo-membrane?

- Commonly used geomembrane specifications include 150 / 0.2 / 150 300 / 0.3 / 300, etc., they are generally divided into two cloth one membrane and one cloth one membrane, it's usually formed by calendering or thermal compound production process. Geomembrane is generally used for the anti-seepage project, for example, reservoir anti-seepage, reinforcement, roadbed anti-seepage, tunnel anti-seepage, airport anti-seepage and other projects.

- Q: What are the limitations of using geomembranes?

- There are several limitations associated with using geomembranes. Firstly, geomembranes are susceptible to punctures and tears, especially during installation or due to sharp objects in the underlying soil. Additionally, geomembranes are not resistant to UV radiation and can degrade over time when exposed to sunlight. Another limitation is that geomembranes may not be able to withstand high temperatures or extreme weather conditions, which can cause them to crack or deteriorate. Moreover, geomembranes require proper installation techniques and quality control measures to ensure their effectiveness, which can be challenging in certain environments. Lastly, geomembranes may not be suitable for all types of containment applications, as they may not provide adequate protection against certain chemicals or contaminants.

- Q: Can geomembranes be used in landfill gas collection systems?

- Yes, geomembranes can be used in landfill gas collection systems. Geomembranes are impermeable liners made of synthetic materials that are designed to prevent the leakage of liquids and gases. In landfill gas collection systems, geomembranes are used as a barrier to contain and collect the methane gas produced by decomposing waste in landfills. They help to prevent gas migration and facilitate the efficient collection and extraction of landfill gas for energy generation or other uses.

- Q: Can composite geo-membrane be used for roof waterproof?

- Geomembrane? Do you refer to geotextile? Main material can be made of polyvinyl chloride PVC waterproof roll and geotextile, stuck by special adhesive powder.

- Q: What is the material of HDPE geomembrane?

- The main materials: High density polyethylene should match color master batch. Double resistant HDPE

- Q: What are the types of geomembranes?

- There are several types of geomembranes, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), ethylene propylene diene terpolymer (EPDM), and chlorosulfonated polyethylene (CSPE).

- Q: How to choose glossy and matte geomembrane used in refuse landfill ?

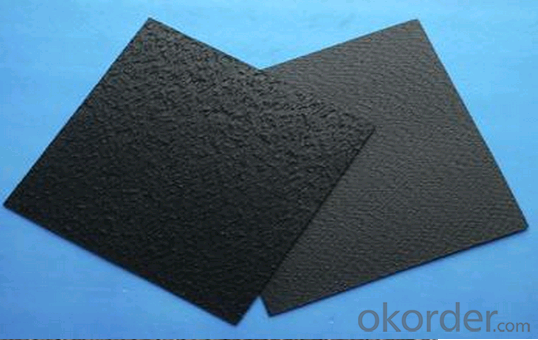

- Hope it is easy to understand because it is not complicated at all. Actually, the dfference between matte and glossy membrane is the coarse surface, which is to increase friction. I f it is for refuse landfill, there are mainly three parts needed geomembrane for seepage-proof. reservoir bottom, side slope and cover (or closure). For "reservior bottom" , pave a layer of imported glossy geomembrane at the bottom of the landfill for horizontal seepage prevention. For side slope, use matte geomembrane around the landfill to increase friction because the side slope has vertical angle, that is, to make the geomembrane hung on the side slope. For cover or enclosure, use glossy membrane for horizontal seepage prevention to prevent rain pouring into the reservior and percolate increasing and isolate the garbage in landfill from the outside. It may not be comprehensive, but from practical experience coorperated with Canada Solmax Inc. Hope it's helpful.

- Q: Does htc phone need to stick film?

- It depends on the personality. After buying the phone, the first thing for some people is to stick film. Although manufacturer repeatedly advertise not to stick film, some people still stick film in order to prevent any accidents while some people do not care. Generally, most screens of android phones are resistant to scratch. So is HTC G14! It is recommended to buy OK8 to stick film for HTC G14 because OK8 is earmarked for G14.

Send your message to us

Venta Geomembrana - Dimple Composite Geomembrane Quality Guaranteed, Low Price Promised

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords