Geotextile Price Per m2 for Reinforcement and Drainage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Key Specifications/Special Features:

Specifications

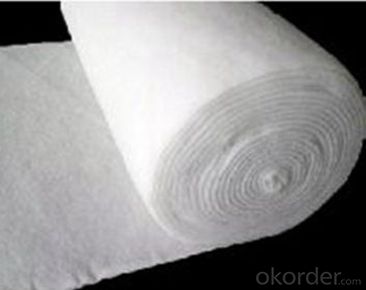

1) PET geotextile: non woven geotextile

2) Material: PP (polypropylene) or Polyester fibers

3) 100g/sq.m-1000g/sq.m

4) Width: 2m-6.5m

Non woven - needle punched, cut fibers geotextiles for protection, filtration, separation, drainage or reinforcement applications (see also woven Geotextiles and Geogrids)

Geotextiles made of virgin Polypropylene PP, Polyester PES

Under request, the geotextile is produced with black carbon to protect from UV

Features

1)Geotextile can make the water flow easily, and form a drainage channel in the soil, and then make the liquid and gas out of the soil.

Make use of its pulling resistance and deformation resistance that can strength the soil to reinforce the stability of the construction structure and improve the soil’s quality.

2) Make the focus proliferate, deliver and decompose efficiently and prevent the soil from destruction from outside factor.

3) Prevent the top and bottom layer’s gravel, soil and concrete from mixer.

4) The mesh cannot be plugged easily – for the strain and moving quality of the network that formed by the antitype fiber.

5) High soaking quality—at the pressure of soil, it also can keep good soaking quality.

6) Corrosion resistant – using the polypropylene and polyester as raw material, it can resist the sour and aid, erosion, boring and oxidation.

7) The construction is easy; the weight is light, convenient for using, and it making construction easy.

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in road construction?

- Yes, geotextiles can be used in road construction. They are commonly used as a part of the road pavement system to enhance the performance and durability of the roads. Geotextiles provide reinforcement, separation, and filtration functions, helping to prevent the mixing of different soil layers, improving load distribution, and reducing the potential for pavement damage.

- Q: Geotextile how to construction?

- There are specialized construction teams

- Q: How do geotextiles contribute to soil drainage?

- Geotextiles contribute to soil drainage by allowing water to pass through them while retaining soil particles. They act as a filter, preventing clogging of the drainage system by soil particles while still facilitating the movement of water.

- Q: What glue glue is used at the seams of the impervious geotextile

- What glue glue is used at the seams of the impervious geotextile

- Q: Can geotextiles be used for reinforcement in retaining walls?

- Yes, geotextiles can be used for reinforcement in retaining walls. Geotextiles are commonly used in retaining wall construction to provide strength, stability, and improved drainage. They help to distribute the load and prevent soil erosion while allowing water to pass through, making them an effective solution for reinforcing and enhancing the performance of retaining walls.

- Q: Construction of composite geotextile

- Geotextile as a protective layer of geomembrane, so that the protection of impermeable layer from damage. In order to reduce the UV radiation, increase the anti-aging properties, it is best to use the laying method. Construction, the first use of smaller diameter sand or clay to find the base surface, and then laying geomembrane. Geomembrane should not be stretched too tight, buried at both ends of the soil part of the corrugated, and finally in the shop on the geomembrane with a fine sand or clay shop layer of 10cm or so excessive layer. Puzzle 20-30cm stone (or concrete prefabricated block) for the anti-Chong protective layer. Construction, should try to avoid the stones directly hit the geomembrane, the best side of the film side of the protective layer of the construction. Composite geomembrane and the surrounding structure should be connected with expansion bolts and steel plate pressure bar anchorage, the connection site to brush the emulsion asphalt (2mm thick) bonding, to prevent the occurrence of leakage.

- Q: What is the role of geotextiles in road construction?

- Geotextiles play a crucial role in road construction by providing reinforcement, filtration, separation, and erosion control. They act as a strong and durable layer between the subgrade and the road surface, distributing loads and preventing soil movement. Geotextiles also filter out fine particles, preventing clogging and maintaining proper drainage. Furthermore, they separate different layers of the road, preventing the intermixing of materials. Overall, geotextiles enhance the longevity and stability of roads, reducing maintenance costs and ensuring safer transportation infrastructure.

- Q: What is the price per square of the non-woven polyester fabric? What is the difference between the geotextile used in the building?

- About two more money it! You can search Yuan Shuqing look! Have to sell! Quite cheap!

- Q: How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement and stability to the soil structure. They act as a barrier against soil erosion, preventing the loss of soil particles and maintaining the integrity of the embankment. Geotextiles also allow water to pass through while retaining the soil, enhancing drainage and preventing water buildup that could weaken the embankment. Additionally, geotextiles distribute the load more evenly, reducing the potential for settling and improving overall stability of the embankment.

- Q: Geotextile price

- Landlord, hello So talk about the geotextile series too much, can not specifically to give you a detailed price, the more common short wire geotextile to tell you about it, the general specifications for the 300 grams of geotextile non-standard to 3.3 yuan / Square meters, the national standard to 3.6 yuan / square meter; specifications for the 400 grams of geotextile non-standard to 4.4 yuan / square meter, the national standard to 4.8 yuan / square meter. Geotextile this thing is now the whole industry based on the price is transparent, different specifications prices are not the same, this thing does not need to ask the manufacturers and asked the manufacturers, because the manufacturers simply can not make a few money, no Need to waste energy on this, as there are still want to know, we ask each other, okay!

Send your message to us

Geotextile Price Per m2 for Reinforcement and Drainage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords