Termite-repellent and Rodent-repellent Nylon Jacket Compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Used for power cable with large size, owning well performance of resistance to brittleness.

2. Description of Nylon compound:

This nylon jacket compound, based on PA6 resin, is produced and pelletized by special technology with adding special modifier, anti-oxidant and other special additives. It has advantages of processing easily, low temperature resistance, cracking resistance, and smooth surface, termite-repellent and rodent-repellent.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

Drying: be dried at 85-100°C for 3-7 hours before use.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die | |

PA1001-D | temperature °C | 230 | 240 | 245 | 245 | 240 | 235 |

PA1001-A | temperature °C | 230 | 240 | 245 | 245 | 245 | 245 |

PA1001-S | temperature °C | 230 | 245 | 245 | 250 | 250 | 255 |

Note: The above temperature is recommended only, and the actual processing temperature should be according to the type of machine and environment.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA1001-A | PA1001-D | PA1001-S |

Standard | Standard | Standard | ||

Density | g/cm3 | 1.14 | 1.12 | 1.14±0.01 |

Hardness | ≥Shore D | 68 | 68 | 65 |

Tensile Strength | ≥MPa | 60 | 50 | 50 |

Elongation at Break | ≥% | 160 | 160 | 50 |

Notched Impact Strength | ≥KJ/m2 | 20 | 20 | 6 |

Volume Resistivity | ≥% | 1.0×1012 | 1.0×1012 | 1.0×1011 |

Dielectric strength | ≥MV/m | 24 | 24 | 24 |

Oxygen Index |

| — | — | — |

Melting point | °C | — | — | -- |

Heat distortion temperature | °C | — | — | -- |

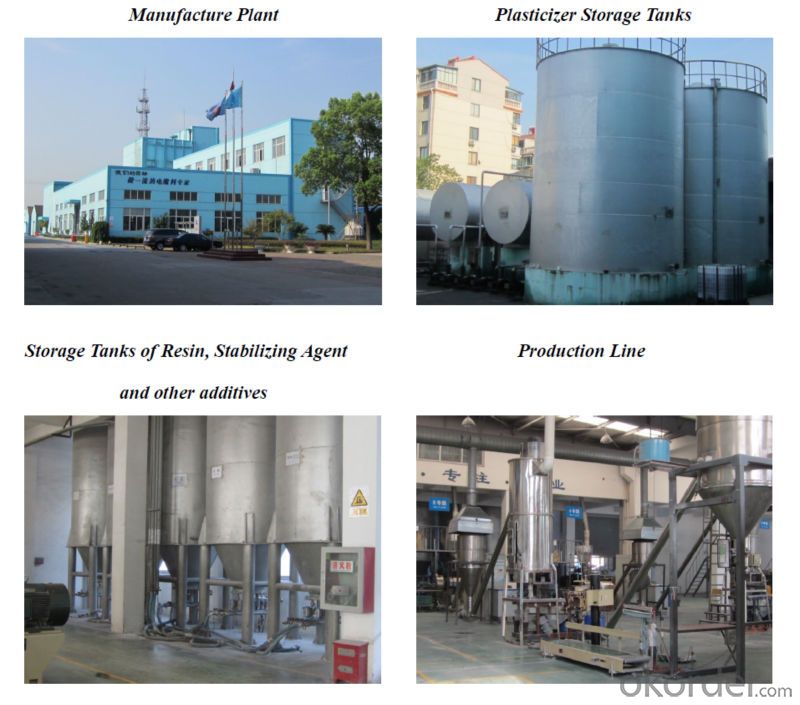

6. Company

- Q: What is the raw material used in the production of plastic products?

- The microwave oven lunch box is made of this kind of material. It is resistant to high temperature at 130 degrees and has poor transparency. It is the only plastic box which can be put into the microwave oven. It can be reused after careful cleaning. Particular attention should be paid to the fact that some microwave oven boxes are made of size 05, but the box cover is made of size 06 PS (polystyrene). PS has good transparency and is not high temperature resistant, so it can not be put into the microwave oven with the box body together. PP. For insurance purposes, put the container in front of the microwave oven and remove the lid first.

- Q: How are plastic products made? What is the raw material of plastics?

- Plastic products are divided into: injection molding, blow molding, spray molding, blister, and die casting. Plastic material is oil. It must be done at a high temperature. The mold you call is usually steel.

- Q: What is the difference between PA66 and PA6 plastic raw materials? Differences in price, color, performance, etc

- Both are nylon series. What about the price, PA66? More expensive. The performance is probably about the same

- Q: Can PE material be used as food grade plastic?

- Plastic film PE the main consumption areas, because of its more and more used in consumption and transportation, the development of the relationship between demand and the overall economic situation is bigger, basically maintain a slightly higher than the national GDP growth, the growth momentum of stable existence of rigid demand. From the flexible packaging film production statistics, since 2006, the average increase rate of 13%, but also confirms the steady growth of plastic film. Another important consumption area of polyethylene is plastic pipe, and its output increases with the pace of urbanization in China, and the increase of municipal pipeline construction projects is increasing. In the next few years, the municipal water supply and drainage, gas pipelines, and urban underground power, communication, sheathing and pipelines will continue to be the focus of development in recent years.

- Q: What is the specific material for plastic pallets?

- There are two kinds of raw materials for plastic pallets: one is polypropylene (PP) and the other is polyethylene (HDPE).Plastic pallets for logistics storage: pp+pe material, recycled material 10%;Plastic trays for food trays: food grade PP, PE, pc;

- Q: How to make plastic raw materials?

- polyethyleneFor short, PE is a thermoplastic resin made by the polymerization of ethylene. Industrially, it also includes copolymers of ethylene with a small amount of alpha olefins. Polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature can reach -70 ~ -100 C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid), insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation properties; but polyethylene for environmental stress (chemical and mechanical function) is very sensitive, heat aging resistance difference. The properties of polyethylene vary depending on the molecular structure and density. The products of different densities (0.91 ~ 0.96g / cm3) can be obtained by different production methods. Polyethylene can be used as a general thermoplastic forming method (see plastic processing). Widely used, it is mainly used for making films, containers, pipes, monofilament, wires, cables, daily necessities, etc., and can be used as high frequency insulating materials for television, radar and so on. With the development of petrochemical industry, polyethylene production has been developed rapidly, and the output is about 1/4 of the total plastic output. In 1983, the total production capacity of polyethylene in the world was 24.65Mt, and the capacity of the equipment under construction was 3.16Mt.

- Q: Does anyone know what kind of plastic material PP-M40 is?

- High gloss PP has high gloss, high fluidity, heat resistance, medium impact toughness and fine processability. The utility model is suitable for making household appliances (rice cookers, vacuum cleaners, electric irons, etc.), office equipment, instruments and meters, beauty equipment, etc..

- Q: What are the raw materials made of modified plastics?

- Broadly speaking, the modification is to change the original performance, such as TPU, flame retardant, anti UV and so on; a narrow sense, the industry will be the new material of TPU polymerization, production is not called modified, and those who buy TPU new material made of flame retardant TPU, called "back modified". The modification process involves adding some resins or additives.

- Q: What are the plastic raw materials for this purpose?

- From the bathroom supplies we use when we wake up, the tableware we use for breakfast, the stationery we use for work and study, the seat cushion for sleeping, the mattress, and the shell of TV set, washing machine and computer

- Q: Chemical, plastic raw materials, plastic raw materials how sub grade?

- That's because the raw material used for making plastic barrels is different. Just like the quality of the clothes, the grades of the fabrics used are different, and the products presented are definitely different.

Send your message to us

Termite-repellent and Rodent-repellent Nylon Jacket Compound for cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords