Fto Glass

Fto Glass Related Searches

Sto Fiberglass Mesh Construction Glass S Glass Fiberglass Black Glass Fiber Tissue Car Fiberglass Fiberglass Roving Fiber Glass Mat Thermal Conductivity Glass Fiberglass Thermal Insulation Fiberglass Woven Fiberglass Roofing Tissue Fiberglass French Doors Fiberglass Patio Roof Glass Fiber Filler Chopped Fiberglass Woven Fibreglass Direct Roving Fiberglass Frosted Plexiglass Fibreglass Mesh Tape Glass Reinforced Epoxy Fiberglass Fabric Fibreglass Fabric Fibreglass Pipes Fiberglass Woven Fabric Fiberglass Distributors Fiberglass Yarn Glass Fibre Surface High Pressure Fiberglass Pipe Fiberglass Roof Philippines Chopped Glass FiberFto Glass Supplier & Manufacturer from China

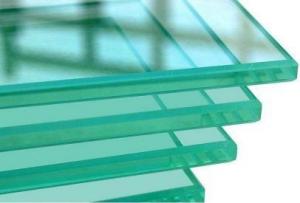

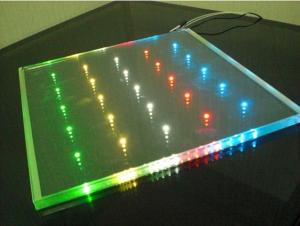

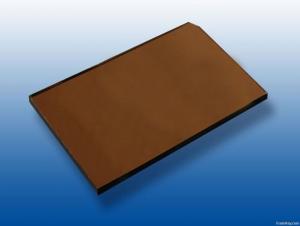

Fto Glass, also known as fluorine-doped tin oxide (FTO) glass, is a type of transparent conductive glass that has gained popularity in various industries due to its unique properties. It is widely used in applications such as solar cells, touch screens, and architectural glass coatings, thanks to its ability to conduct electricity while maintaining high light transmission. This versatile product is designed to meet the demands of modern technology and sustainability, providing a reliable solution for a range of applications.In terms of usage, Fto Glass is utilized in a variety of scenarios, from the production of efficient solar panels to enhancing the functionality of electronic devices. Its conductive and transparent nature makes it an ideal material for creating energy-harvesting surfaces and improving the user interface of various gadgets. The product's durability and resistance to environmental factors also make it suitable for architectural applications, where it can be used to create smart windows that regulate heat and light, contributing to energy efficiency in buildings.

As a leading wholesale supplier, Okorder.com offers a vast inventory of Fto Glass, ensuring that customers have access to a reliable and high-quality product. With a commitment to providing top-notch service and support, Okorder.com has established itself as a trusted source for Fto Glass and other related materials. Their extensive stock allows customers to find the exact specifications they need, whether for research, development, or large-scale production.

Hot Products