Borosilicate Float Glass 4.0 for Building Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

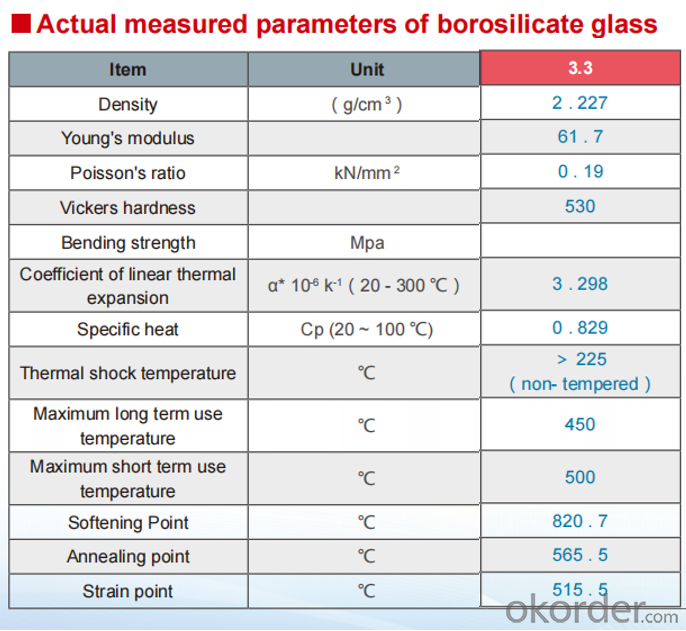

1. Description:

Borosilicate glass, also known as high borosilicate glass, is known as the "King of Glass".

Its main component is about 80% silicon oxide and about 10% boron oxide.

At this time, both silicon oxide and boron oxide can basically form microtetrahedrons.

Framework (the more the micro tetrahedral framework in the glass is, the greater the ionic bond force will become, contributing to a more stable performance), the other is about 5% of stable oxide and about 5% of flux.

2. Main Features:

3. Advantage:

Float Glass is superior in quality when compared to other flat glass and has the unique characteristics of excellent surface finishing, flatness, uniform thickness, high optical quality and bright appearance.

The float process was invented in 1952.

Float technology has rapidly replaced plate and sheet facilities worldwide in recent decades.

Float glass derives its name from the float process used where the molten glass floats on the top of molten tin.

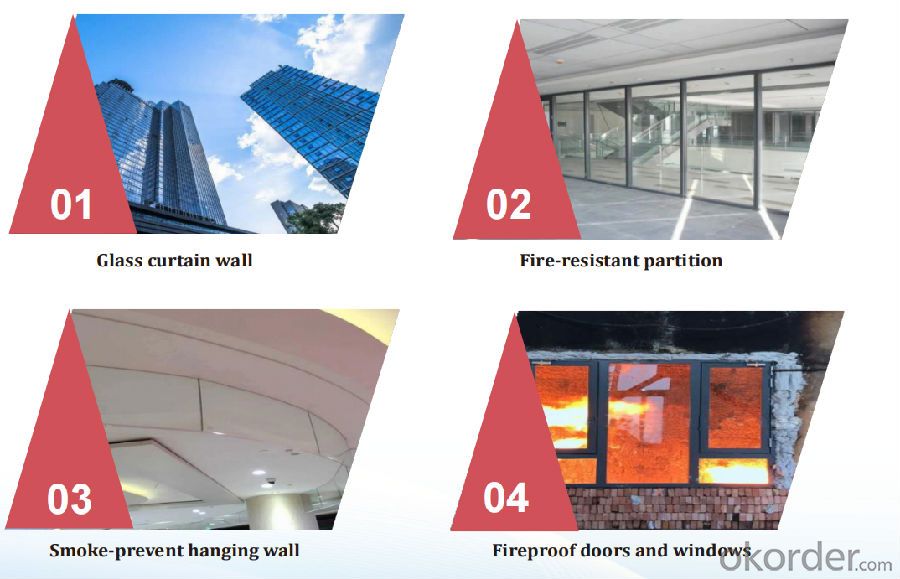

4 . Application Area:

Can be used in fireproof curtain walls, partition walls, platforms, day lighting roofs, smoke-proof vertical walls, railings, doors and windows, elevator shafts, rail transit platform screen doors, rail locomotive doors and windows and other fields.

Equipped with water spray, it can be used to replace Class A insulation type fireproof glass system, which can be widely used in building atrium, pedestrian street fireproof glass and building fireproof partition.

5. Company Brief:

6. Packing & Shipping:

All the glass will pack in strong export plywood crates, and load in container strong firmly, to make sure safety delivery.

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Organic glass is an important heat, a development of earlier plastic, with transparency, chemical stability and good weathering resistance, easy to dye, easy processing, beautiful appearance, is widely used in the construction industry. The plexiglass product usually can be divided into casting plate, plastic extrusion board and the mold.Acrylic is much more expensive than plexiglass

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber is divided into different grades according to its composition, properties and uses. According to the provisions of the standard level (see table), E glass fiber is most widely used, widely used in electrical insulating materials; special fiber grade S, while the output is small, but very important, because it has super strength, mainly used for military defense, such as bullet proof box; C level more than E with chemical resistance in the battery isolation plate, chemical filter; a basic glass fiber reinforced materials used in the production.The main component of glass fibre and its main components are silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide, depending on the amount of alkali content in glass, can be divided into non alkali glass fiber (Na2O 0% ~ 2%, which belongs to the aluminum borosilicate glass), glass fiber (8% ~ sodium sodium calcium silicate glass 12%, a boron containing or not containing boron) and high alkali glass fiber (Na2O 13%, sodium calcium silicate glass).

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: Comparison of plexiglass steel bridge and inorganic glass steel bridge

- 4, can release harmful gases, human health and environmental protection have a certain impact. 5, high cost, but also a larger fluctuation of raw material prices. 6, after the waste is not easy to handle. Two, inorganic glass fiber reinforced plastics (referred to as Magnesium Oxide) advantages: 1, high temperature. (under normal circumstances, Fahrenheit temperature of 400 degrees Celsius, to maintain the product is not deformed), 2, anti-aging, 20 years without deformation of the product. 3. Purify the air and absorb carbon dioxide from the air. 4, high strength. 5, waterproof performance is good. 6, light weight, only in plexiglass.

- Q: The preparation process of glass and the basic material and the function of raw materials

- The main raw materials are: silica glass (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: liquid glass forming device with the corresponding sheet glass, bottles, glass, lamp, glass tube, a fluorescent screen......6, annealing: the molding of a variety of glass products into the annealing furnace annealing, balance stress, to prevent self cracking

- Q: What is the raw material of glass? How is it converted to glass?

- Formed by converting molten glass to a solid product of a fixed shape. The process must take place within a certain temperature range. This is a cooling process. The glass is first converted from a viscous liquid to a plastic state, and then to a brittle solid. The forming method can be divided into two categories: manual forming and mechanical forming.

- Q: What's the difference between crystal and ordinary glass?

- To strike lightly or with fingers. Crystal glass can produce metal crisp sound, and waves a beautiful lingering in the air. We will see at the reception banquet, high-end glasses scenes in the movie, a kind of glass between the collision sound is. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.

- Q: May I ask what specific aspects of German foam glass and foam glass made in China are?

- Germany first foam glass from the production process is automatic production line, proportion of raw materials, mixing, grinding, into the furnace foaming, stripping, pipeline operations, and 24 hours of uninterrupted production, full computer monitoring, the whole process of online cutting, according to the requirements of automatic generation of the required thickness and size. 100% waste glass as raw material.

- Q: Use of glass flake cement

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake could commission a heat stable layer, which can prevent the substrate cracking and spalling.

- Q: Mobile phone film new flexible toughened glass membrane, really is the glass?

- The toughened film is designed to prevent the phone from slipping and crashing the screen. Not to prevent scratching. Ordinary film is the hardness of 3H, the use of a few months, there will not be too much scraping, the reason why the election of the steel screen is: high hardness, low toughness, mobile phones fell, can be very good anti broken screen. When the mobile phone drops on the ground, the impact is great, the tension is too large and the screen is broken. Toughened film toughness is low, when the handset sends out the tension, the membrane can bear the tension, thus greatly reduced the main screen to bear the tension.

Send your message to us

Borosilicate Float Glass 4.0 for Building Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches