Colored borosilicate glass tube for Mouth blowing glasswares

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 20000000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description:

Using the latest technology, our coloured borosilicate glass tubing3.3 correspond to the internationally acknowledged borosilicate glass type 3.3(DIN ISO 3585).

All stages of production are strictly controlled and backed up by a complete quality control system according to ISO9002.

Till now we can supply eleven kind of colors: transparent black borosil glass tubing, teal borosilicate glass tubing, dark blue borosilicate glass tubing, dark amber borosilicate glass tubing, pink borosilicate glass tubing, opaque black borosilicate glass tubing, yellow borosilicate glass tubing, red borosilicate glass tubing, green borosilicate glass tubing etc

2. Technical Description

Regular Specification: 25*4mm, 32*3.2mm, 32*4mm, 38*3.2mm, 38*4.0mm, 44*4.0mm, 51*4.0mm, 51*4.8mm etc.

Color high borosilicate glass is a kind of hard glass, Coefficient of thermal expansion is 3.30.1*10-6/K.

It is a kind of special glass material which is low inflation, high temperature resistant, high strength, high hardness, high light transmittance and high chemical stability. Because of its molecular structure is more closely, so even very thin is still strong and durable, The glass is colored at temperatures above 1600 degrees, so color is bright such as crystal clear, the color is never changed. In the production process, the technician keeps spinning the embryo and pulling it into a grain written. So observed in the sun, there are some textures, this is the normal glass process phenomenon.

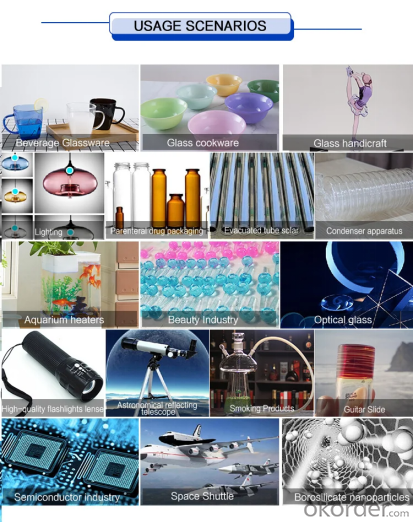

3. Widely usages of borosilicate glass tube

1. Kitchenware

2. Lighting Decorations

3. Chemical equipment

4. Solar Vaccum Tubes

5. Glass Arts & Crafts

6. Glass Smoking Pipes

7. Medical Pacakaging

8. Laboratory Instruments

4. Advantages

1. High quality,competitive price and elegant appearance

2. Accurate dimension according to customs' request

3. Long time to use

Customize specifications according to your demands:

O. D from 4mm~315mm,

W.T from 0.8mm~9mm,

5. Business Terms

Delivery time: Within 20days after received the advance payment.

Payment: 30%-50% TT in advance and balance against copy of BL.

Transport: By ship or express

Colors available: opaque black, opaque white, pink,purple, green,yellow, amber,dark blue, light blue, transparent blac

Usage:

6.

Process:

7. Packing and Shipping:

All the glass will pack in cartons, and load in container strong firmly, to make sure safety delivery.

8. Test Report

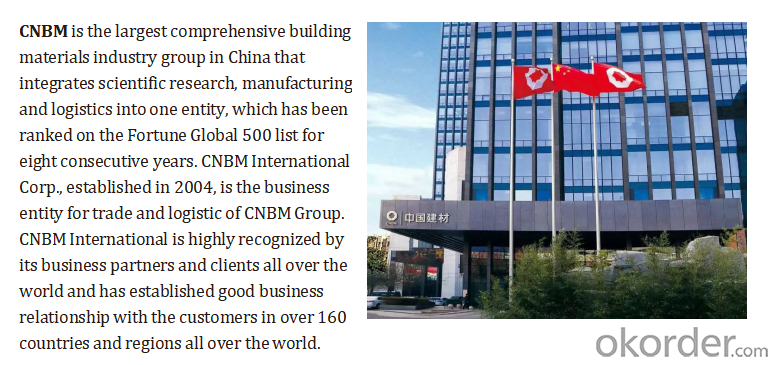

9. Company Brief:

10. FAQ:

Q1: Are you factory or trading company?

A: We are manufacturer in Hebei Province near Beijing,and we also have trading office in Beijing.

Q2: Can support OEM&ODM order?

A: Yes,we have rich experience in OEM&ODM production, can meet your personalized needs.

Q4: Can you do the designs for us?

A: Yes.We have a professional team having much experience in designing and manufacturing.Just let us know your ideas,we will draw the finished files for your confirmation.

Q5: What format of the file do you need if I want my own design?

A: You can provide JPG,Al,or PDF etc,Our professional designer will draw art work for mould or printing screen for you.

Q6: How can I get some samples?

A: Sure,we usually provide existing samples for free.But a little sample charge for custom designs,Sample charge is refundable when order is up to certain quantity.

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- There are ultra white solar glass. Dedicated to this solar energy

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- There's no problem with fiberglass mesh.

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- The main raw materials of flat glass are: silica sand (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.

- Q: What is the ratio of raw materials for glass mildew proof powder?

- Features: using high-quality coconut shell as raw materials, by crushing, mixing, extrusion, drying, modification and so on;R & D institutions: Department of chemical and chemical engineering of Nanjing University, GREE R & D institutions, Department of environmental science, Nanjing University, Jiangsu physical and chemical testing center;Advanced: for the domestic initiative, greatly solved the domestic construction materials, such as glass mildew problems, environmental protection is good, in line with Europe and the United States and other countries

- Q: Glass fiber reinforced plastic (FRP) is a new type of composite material. What is the raw material?

- The first type of glass fiber reinforced plastics is a composite of glass fiber and phenolic resin. It is a glass fiber impregnated with phenolic resin liquid raw material, after molding, pre molding, and then the phenolic resin curing, made of glass fiber reinforced plastic. Corrosion resistance and long service life. Glass fiber reinforced plastic is a kind of high-quality composite material. It has a special anti-corrosion function for acid, alkali, salt, oil and other corrosive media, and will not rust. The average PVC life is 15 years, while the glass steel life is 50 years.

- Q: The preparation process of glass and the basic material and the function of raw materials

- Silica sand, quartz sand or sandstone with SiO2 framework structure for glass, glass forming;The role of soda to help melting sand;

- Q: What's the difference between three kinds of glass fiber board, epoxy board and FR4 board?

- FR4 is the pure epoxy board of NEMA standard. The normal color should be dark green. This is the color of epoxy. There are also yellow, generally called yellow FR4 called yellow material, white (green) called white material.FR4 is more expensive than epoxy board and fiberglass board cannot confirm the price.

- Q: What happens when toughened glass breaks?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: What kind of film is toughened glass film?

- How to identify good protective film for toughened glass:1., bad exhaust surface residual bubble phenomenon;2., toughened glass can not stick around the corner, bubble phenomenon;3., toughened glass and mobile phone adhesion, easy to fall off phenomenon;4., toughened glass is too thick, affecting transmittance, and thickening of mobile phone thickness;5., toughened glass sticking glue is too thick, affect the mobile phone display transmittance;6. toughened glass is pasted on the mobile phone, and the surface of the mobile phone has a watermark phenomenon.7., toughened glass film is also straight edge and arc edge, arc edge relative to the more rounded, not easy to hurt hand

- Q: The difference between natural crystal and crystal glass, merits and demerits!

- Crystal glass, also known as lead crystal glass, this is a glass, but because of its luster, texture, sound and other characteristics are very similar to natural crystal, so called crystal glass.

Send your message to us

Colored borosilicate glass tube for Mouth blowing glasswares

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 20000000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches