Ampoule ISO Standard YBB Standard High Quality

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ampoule ISO Standard YBB Standard High Quality

Neutral borosilicate glass is far superior to low borosilicate glass in terms of hydrolitic resistance, acid and alkali resistance, freezing resistance, filling speed,etc. and it is not easy to cause delamination"due to chemical soaking and corrosion. It is an internationally recognized safe pharmaceutical packaging materials.

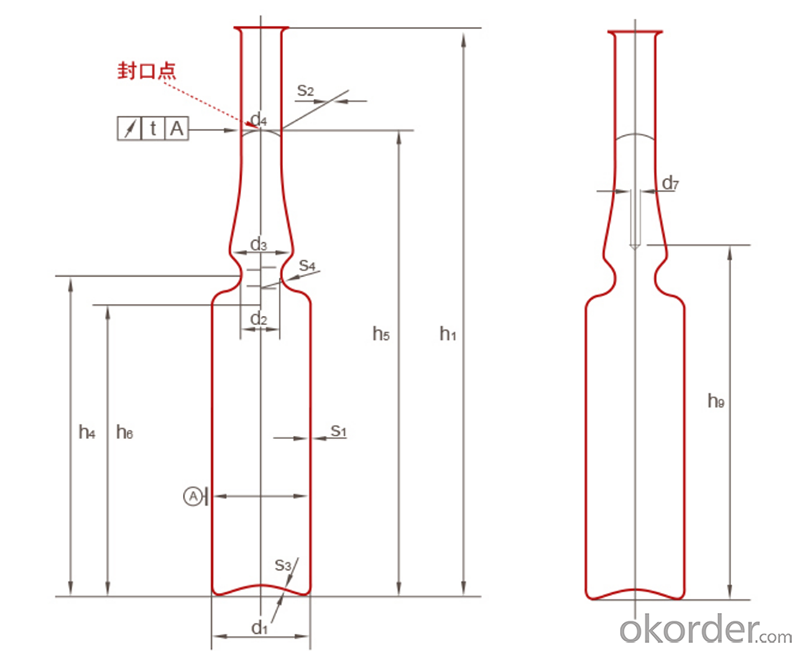

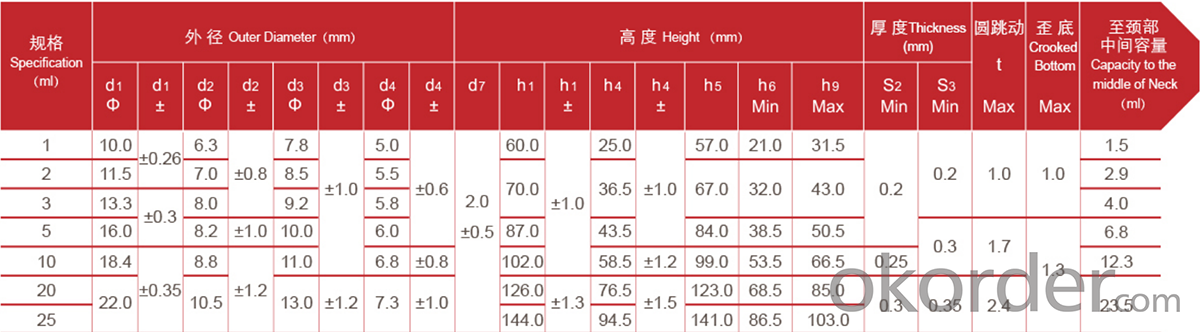

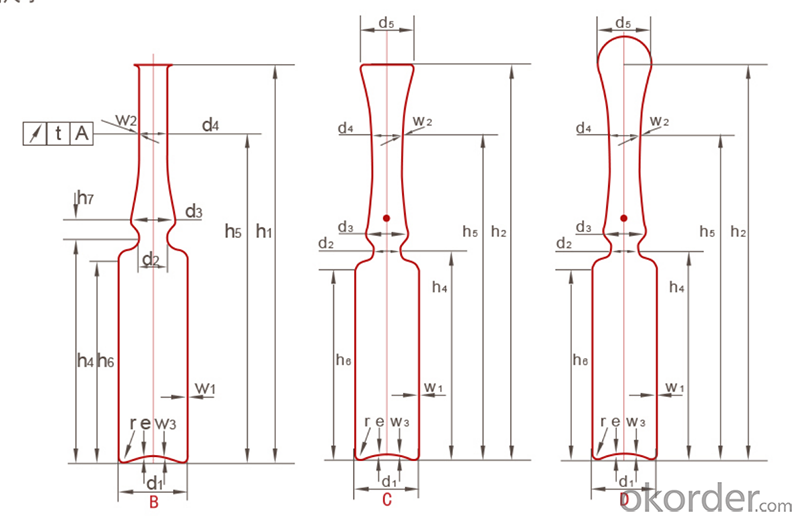

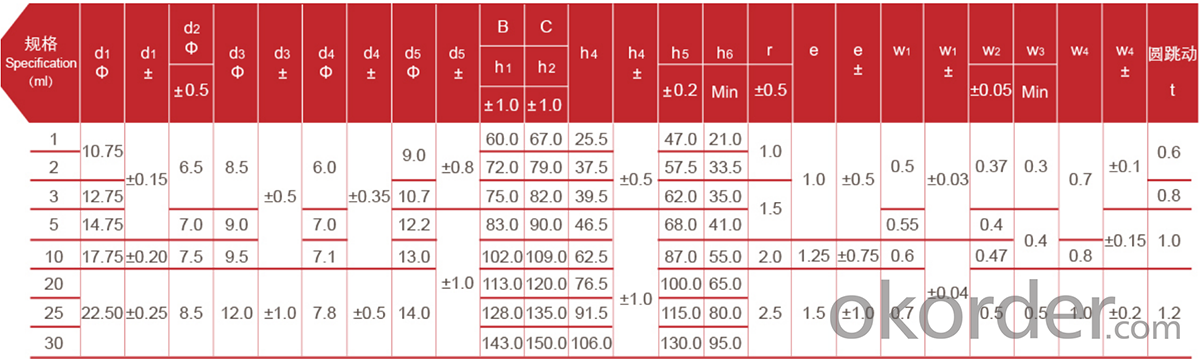

Ampoule YBB Standard

Ampoule ISO Standard

The converting products workshop of the plant has a 100000-level clean room that meets GMP standards, which provides superior production conditions for the production of glass containers and effectively avoids the impact of dust and bacteria on product cleanliness. The inspection system with 7 cameras and 360 continuously rotating and shooting, to detect the glass container body,mouth, shoulder, bottom,inner diameter,edge blind area and mouth bottom edge, as well the dimension, objects inside the container, cosmetic defects (bubbles, impurities and stones).The unqualified products such as crooked container are automatically eliminated, with a detection accuracy of 0.02mm, which ensures that the quality of the glass containers can reach the domestic YBB standard and the international ISO standard. "Excellence Centre"is a project established by Triumph Group and the world leading pharmaceutical packaging material manufacturer-Stevanato Group(Italy). The goal is to introduce world standard tubular glass containers production technology, technical process and quality standards to the Chinese market and make our company's products to keep up with international top standard.

Nationwide Seven Production Bases to Meet the Customers' needTriumph Junheng Co.,(hereinafter referred to as "Triumph Junheng") is a state-owned andprivate mixed ownership enterprise, Triumph Group of CNBM is the controlling shareholder.It ismainly engaged in the research and development, producing and sales of neutral Borosilicateglass tubing(hereinafter referred to as "Neutral Borosilicate glass tubing") and convertingtubular glass products. It has seven production bases located in Handan, Qingdao, Chongqing,Puyang, Anyang, Nanchang and Zhenjiang, which are expected to produce totally 170,000 tons of glass tubing and 136,000 tons of tubular glass container when they are reach full capacity. It is the first high-tech company which realizes stable mass production of high-quality Neutral borosilicate glass tubing with its "oxygen combustion + electric boosting"melting and Danner Tubing drawing technical process in China. It has leading R&D capabilities in the domestic pharmaceutical glass packaging industry, and can provide professional and personalized solutions of pharmaceutical glass packaging materials for materials for tubular glass converting and pharmaceutical companies.

Triumph Junheng builds a comprehensive research and development center for pharmaceutical neutral borosilicate glass in accordance with CNAS certification specifications. Continuously improve the level of laboratory quality management, minimize product quality risks, and meet the requirements of customers and regulations for the authenticity and reliability of testing/calibration to the greatest extent. The R&D center has a team with 30 people, covering various key technical fields such as raw materials analyzing, batching, melting, forming,and post-processing. The center has a building area of 800 square meters and consists of a precision instrument room, a physics laboratory, a chemical laboratory, a balance room, and a high temperature laboratory., Reagent room, equipped with 30 sets(sets)of R&D equipment such as atomic absorption spectrometer, expansion coefficient meter, and electron microscope. The R&D

center focuses on new technologies, intelligence, low energy consumption, localization and standardization, and actively undertakes national and local R&D projects to continuously achieve new technological breakthroughs.

Companys proucts have passed the Qulity inspection and Testing conducted by the national authoritative inspection agencies: Beijing Pharmaceutical Packaging Materials Inspection Institute and International Third Party Testing Agency-SGS. The product quality is fully in line with EP (European Pharmacopoeia), USP United States Pharmacopoeia),JP (Japanese Pharmacopoeia),According to the standard requirements of ISO12775 and the standard of "Neutral Borosilicate Glass Tubing" with Code YBB0012005-2-2015 approved by The National Food and Drug Administration. The expansion coefficient, boron content and hydrolitic resistance of products all have reached the international advanced level.

Quality Inspection

The international advanced automatic online inspection system has been adopted in the production line, which can automatically eliminate unqualified products with defects of dimension and cosmetic and unaligned ends treatment.

Automatic Packaging System

The automatic packaging system can complete the work of heat-shrinking into bundles and stacking into trays, effectively avoiding cosmetic defects such as scratches and impacting caused

by manual operation, ensuring the fastening of each bundle of products and the neatness of each tray.

- Q: What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- Zircon sand is the most important zirconium containing mineral, which has the widest distribution, largest reserves and most types in zirconium minerals. It is a kind of mineral with zirconium silicate as the main component. Zircon sand is the main raw material for preparing zirconium, hafnium and many kinds of zirconium products. It has the characteristics of high melting point, low thermal conductivity and small coefficient of linear expansion. It is widely used in metallurgy, casting and other industries.Zircon sand (Gao Yingshi) is highly resistant to heat and has a melting point of 2750. Acid corrosion resistance. 80% of the world's direct use in the foundry industry, ceramics, glass industry, and the manufacture of refractory materials. A small amount used in ferrous alloys, pharmaceuticals, paints, tanning, abrasives, chemicals, and nuclear industries. Very little is used in smelting zirconium metal.

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- Glass fiber reinforced plastic used for raw materials, resin, glass fiber reinforced plastic fiber silk, filler, calcium powder to 1:1:1 ratio configuration, high-quality glass fiber reinforced plastic choose high-quality resin: unsaturated ortho benzene resin 196, colorless transparent. Low viscosity, low heat release, low shrinkage, high speed cure, high speed compatibility and gloss.

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- At present, there are three kinds of insulating glass in China: (1) groove aluminum type single channel sealing; (two) groove aluminum double channel sealing; (three) compound sealant strip type insulating glass.

- Q: Acrylic plexiglass rod can be used in what way?

- Adhesive: two components. One component and two components, such as adhesive and epoxy resin; one component, such as CCl3 (Lv Fang). A two-component adhesive through curing reaction to achieve bonding, one component adhesive is a volatile solvent and finally realize bonding. The two component adhesive is characterized by good bonding effect, no bubbles, no white and strong strength after bonding.

- Q: The main reasons for failure of air glass are outlined

- The production of hollow glass raw material quality; key factors affect the service life of hollow glass sealant is ageing resistance and desiccant adsorption capacity, and the determining factor is the performance of sealant. Because no matter how much the desiccant adsorption capacity, inside the hollow glass after a certain limit, when the hollow glass desiccant completely saturated, again good desiccant also unable to water vapor adsorption, then the hollow glass is invalid. Only when the sealant has good sealing performance, moisture permeability coefficient is low, the amount of water vapor into the hollow glass rarely, and keep this state, only rarely can guarantee the hollow glass desiccant inside gas drying, so as to ensure the effect of hollow glass. To keep the sealant unchanged for a long time, it must require the sealant has good anti-aging properties, if the material quality is not good, it will affect the life of hollow glass products, in all sealants, most can reflect is butyl rubber as the basic raw materials of various types of sealant sealant and moisture barrier properties, and so on standard hollow glass curtain wall curtain wall must adopt double sealing is a very correct decision. Here are a variety of sealants water vapor permeability coefficient table, from the table we can see that the structure of glue can not be used as insulating glass sealant alone.

- Q: Which is the best solar water heater tube?

- The surface of the vacuum heat collecting tube is smooth and clean, the pipe body has no spots, no air lines, no scratches and no film forming. (this phenomenon will affect the collection efficiency and beauty).

- Q: How do you pack something into (Qian Jin) plexiglass?

- The organic glass is divided into two layers to seal the flat object and then polish it.

- Q: Why is the process of glass toughened always broken?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: The younger brother wants to know how the octagonal bead is produced Do you use one side of the machine to grind it? What kind of material is usually used in China? Is the price fixed according to the material used?

- B grade crystal beads: flat emery discs are cut one by one, and polished by batch machines with a polishing machine!

- Q: What is the glass industry?

- The glass belongs to the chemical industry, glass production process mainly includes: raw material processed. The massive raw materials (quartz sand, soda ash, limestone, feldspar) grinding, wet material drying, iron containing raw materials for iron removal treatment, in order to ensure the quality of glass batch preparation. 2. The melting of glass batch. High temperature in the furnace or crucible kiln (1550~1600) heating, so as to form uniform, no bubbles, and meet the requirements of molding liquid glass.

Send your message to us

Ampoule ISO Standard YBB Standard High Quality

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches