ITO Glass for Display

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ITO Glass is manufactured through coating ITO transparent conductive layer on single side or double sides of glass according to the advanced technology of vacuum magnetron sputtering. It is the critical material for producing resistive or capacitive touch screens. When used on LCD, a SiO2 layer should be added before coating ITO layer on glass to prevent the ions of glass substrate from penetrating into the conductive layer. If it is requested for higher transmittance, one or multiple AR (anti-reflective) layers can be added before coating ITO layer on glass, thus making it the high-transmittance ITO conductive glass.

Features of Display ITO Glass:

Resistance Uniformity:≤±0.1

Film Thickness Uniformity:≤±0.1

Good adhesive force

Good etching property

Good resistance to acid and alkali

Specifications of Display ITO Glass:

Thickness: 2.0mm; 1.1mm; 0.7mm; 0.55mm; 0.4mm; 0.3mm; etc. (with ±0.05mm tolerance)

Size:

14*14"; 14*16"; 20*24";

355.6*406.4mm; 370*470mm; 400*500mm,450*550mm;550*650mm; etc.

Resistance:

High (150-500Ω) used for ESD protection, Touch Screen control;

Average (60-150Ω) used for TN-LCD, electronic anti-interference;

Low (<60Ω) used for STN-LCD, transparent circuit board, etc.

Applications of Display ITO Glass:

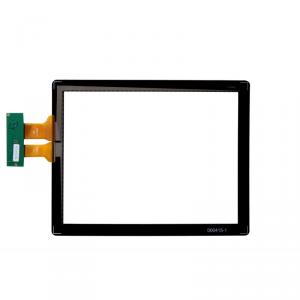

ITO Glass, as a kind of TCO glass, is mainly used to produce display screen, touch screen, mobile phone panel, home appliance panel and others.

ITO Glass used for TN-LCD/HTN-LCD/STN-LCD/TFT-LCD/PDP/OLED/VFD/LCOS in the application of vehicle, consumer electronics, industrial products, LCD (liquid crystal display):

surface resistance: 3.5-100Ω

thickness: 0.4-1.1mm

ITO Glass used for touch screen in the application of mobile phone, displayer, GPS, PDA, instruments and apparatuses, etc.

surface resistance: 150-600Ω

thickness: 0.4-3.0mm

- Q: The glass door in the shower room is too heavy. What material can be substituted, which is as transparent as glass but lighter than glass?

- Features: weathering and acid and alkali resistant performance is good, not because of years of sun and rain, and yellowing and hydrolysis phenomenon of long life, compared with other materials, life is 3 years good translucent, can reach more than 92%, the light intensity less required, saving electric energy impact force, is sixteen times ordinary glass, particularly suitable for installation in the safety zone, than the ordinary glass half light, convenient maintenance, easy to clean.

- Q: Why a broken glass film

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: What material can not be sprayed on the glass?

- 1.. First spray the glass and then stick it on the outside with a transparent adhesive tape..2. uses the special printing ink for the glass product, 3. uses the glass glue to adjust the soluble pigment and the dye toner. 4. go to the print shop and do the writing, then glue it on. I hope my answer will be of some help to you

- Q: What kind of material is made of automobile glass?

- Glass raw material, main raw material, quartz sandThe main raw material of automotive glass is pressure PVB and glass substrate

- Q: Tempered and reinforced glass

- Enterprises producing safety glass must pass compulsory certification by the state, otherwise they are not allowed to appear on the market. Therefore, toughened glass has the following signs:Tempered glass, if made into reinforced glass, is substandard products.10mm toughened glass generally costs less than 100 yuan. Paint and not much money, but if the price is higher glaze.

- Q: Who can tell me the raw material and function of the flashy glass?

- The roll of the roll is rotated, and the glass belt is pulled out of the tin groove into the annealing furnace. After annealing and cutting, the flat glass product is obtained.

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- When the glass is heated to a suitable temperature, it cools rapidly, causing a sharp contraction of the glass surface and a compressive stress, while the cooling in the middle of the glass is slower and it is too late to shrink, thus forming a tensile stress and making the glass obtain a higher strength. Generally speaking, the higher the cooling intensity, the greater the strength of the glass.

- Q: Does the material of sunglasses choose good glass or plastic?

- Glass materials of high hardness, not prone to scratches, shock resistance is poor, after the impact of easily broken, and the weight is relatively heavy.

- Q: What kind of film is toughened glass film?

- How to identify good protective film for toughened glass:1., bad exhaust surface residual bubble phenomenon;2., toughened glass can not stick around the corner, bubble phenomenon;3., toughened glass and mobile phone adhesion, easy to fall off phenomenon;4., toughened glass is too thick, affecting transmittance, and thickening of mobile phone thickness;5., toughened glass sticking glue is too thick, affect the mobile phone display transmittance;6. toughened glass is pasted on the mobile phone, and the surface of the mobile phone has a watermark phenomenon.7., toughened glass film is also straight edge and arc edge, arc edge relative to the more rounded, not easy to hurt hand

- Q: Failure reasons and solutions of insulating glass.

- The production of hollow glass raw material quality; key factors affect the service life of hollow glass sealant is ageing resistance and desiccant adsorption capacity, and the determining factor is the performance of sealant. Because no matter how much the desiccant adsorption capacity, inside the hollow glass after a certain limit, when the hollow glass desiccant completely saturated, again good desiccant also unable to water vapor adsorption, then the hollow glass is invalid. Only when the sealant has good sealing performance, moisture permeability coefficient is low, the amount of water vapor into the hollow glass rarely, and keep this state, only rarely can guarantee the hollow glass desiccant inside gas drying, so as to ensure the effect of hollow glass.

1. Manufacturer Overview

| Location | Hebei,China (Mainland |

| Year Established | 1999 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

ITO Glass for Display

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords