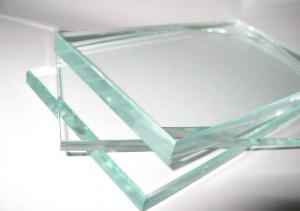

Ultra Clear Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ultra Clear Float Glass is a kind of low iron and transparent glass with high light transmittance(>91%), also called low iron glass. It is a high-quality, multifunctional and newly high-end glass. Being crystal clear and elegant, it is crowned as "crystal prince" of the glass family.

Features of Ultra Clear Float Glass:

1. High clarity: 6% higher visible light transmittace than ordinary clear glass;

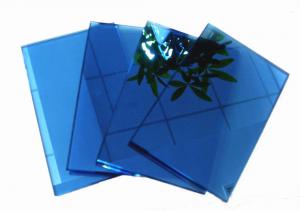

2. Nobility and elegance:with the unique lavender edges , it has the feeling of the the sapphire against the sunshine.

3. Safety: No detonating impurities/metallic and no spontaneous detonation.

4. Low UV transmittance and Environmentally friendly products: can effectively prevent UV radiation and protect interior items from fading and aging.

5. CE/SGS/REACH Certificates.

Specifications of Ultra Clear Float Glass:

Thickness: 2- 25mm

Size:

920*1016mm

3660*18000mm

Customized Sizes

Applications of Ultra Clear Float Glass:

Ultra Clear Glass has been widely used in various fields:

1. Interior and Exterior Decorations of Advanced Buildings: like curtain walls, glass doors of the lobby, transparent roof, glass ribs, glass suspended ceilings, partitions, walls, guard rails, stairs, etc.

2. Exhibition Hall and Showcase: in museum, exhibition hall, jewelry shop, clothing store, etc.

3. Home Appliances: as the screen protector of plasma TV, high-end visual refrigerator door, high-grade microwave oven panel, refrigerator cover, range hood cover, etc.

4. High-end Arts and Crafts, Lamps, etc.

5. Furniture and Bathroom Products.

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials for producing ceramics are clay (such as Suzhou soil), quartz, feldspar (potassium feldspar and albite)

- Q: What are the aluminum films used in glass processing enterprises?

- (1) the enterprise purchase and acceptance of storage materials, the planned cost or actual cost, debit "raw material" subjects, according to the actual cost of credit "material procurement" or "goods in transit" subjects, according to the difference between the planned cost and actual cost, debit or credit "material cost difference" course.

- Q: What are the chemicals in glass?

- Common raw materials are quartz sand, feldspar, calcite, calcium carbonate, three, two aluminum oxide, sodium carbonate, borax and so on.

- Q: There are several appearances of the quality defects of ordinary flat glass

- If molten glass contains gas, it forms bubbles when it is formed. Bubbles mainly affect the transmittance of glass, reduce the mechanical properties of glass, but also affect people's vision, resulting in deformation of the biological image, the main reason is that the purity of raw materials is not enough.

- Q: Consult the experts on injection molding. Injection of raw materials Riga glass material, OK?

- If the request is not high, it can be added, but the hollow words are not good, if there is anything that does not understand, speak out, give me 10 points first

- Q: What are the raw materials of water glass?

- The water soluble alkali metal silicate glass is formed by the combination of alkali metal oxide and silica, also called paohuajian. Water glass can be divided according to the type of alkali metal sodium silicate and potassium silicate, the molecular formula of N and K2O.nSiOz. in Na2O.nSiO2 coefficient is called the modulus of water glass, molecular oxidation silicon and alkali metal oxides in water glass ratio (or molar ratio). The modulus of water glass is an important parameter of water glass, generally between 1.5-3.5. The greater the modulus of water glass, solid water glass is difficult to dissolve in water, which can dissolve in water at room temperature for n 1, n is required to increase the water solubility. N is greater than 3 to 4 above atmospheric pressure steam can be dissolved. The modulus of water glass is larger, more silicon oxide content, water glass viscosity, easy decomposition hardening, bond strength increases.

- Q: What happens when toughened glass breaks?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: FRP process piping manufacturing process?

- Glass tube wall structure from inside to outside are: glass fiber reinforced plastic lining layer, glass fiber reinforced plastic sub lining layer, glass fiber reinforced plastic winding layer, glass fiber reinforced plastic external protection layer.

- Q: What kind of raw material does glass form? What is the general smelting process?

- Melt him, place the impurities in the mold, and then cool, and then the glass

- Q: What's the difference between heat resistant glass and tempered / reinforced glass?

- Resistance to cold shock resistance, thermal shock test by 120 DEG C, the temperature difference of 200 degrees changes without deformation, has a very low coefficient of thermal expansion, so the anti blast temperature is not easy to deform and explode, has good thermal stability, impact resistance. High chemical stability and mechanical properties.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1992 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Africa; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ultra Clear Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords