Clear Float Glass Manufacturer 2-19mm Good Quality Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Clear Float Glass:

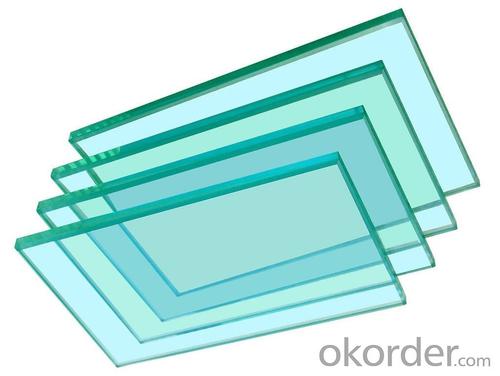

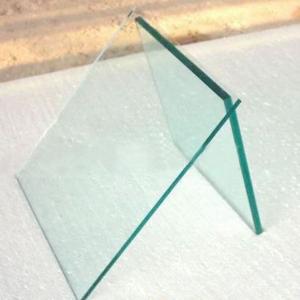

Clear Float Glass is the highest quality clear float glass with smooth surface. Characterised by its uniform thickness, SGG Clear Float is highly popular in the construction of architectural exteriors and interiors, shop windows, showcases, mirrors, furniture, tabletops, and so on.

2.Main features of Clear Float Glass:

.SGG Clear Float Glass is a high-quality glass with precise surface flatness which ensures 100% distortion-free vision.

.It has a crystal clear finish which ensures perfect clarity of vision, with both true and reflected images appearing very bright and clear with this glass.

.Due to its superior quality of manufacture, SGG Clear Float Glass has a sparkling and brilliant luster.

3.Clear Tempered Glass:

4.Clear Tempered Glass Specification:

5.Our factory

6.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Because I work in the glass curtain wall project, only know raw materials to do a glass curtain wall material impact strength test before installing the unit model, in a special laboratory, no experimental requirements should be in the process of construction, the construction of the end of may do some water resistance experiment. Hope to be of help to you!

- Q: Glass factory raw materials specific to do?

- The glass factory is to produce glass raw materials of dolomite, sandstone, soda ash, mirabilite and so on materials in proportion to reconcile into a block by mechanical device to melt kiln.

- Q: What's good with a cup?

- Pure porcelain, porcelain, glass, these basic is non-toxic and good some of the porcelain. The problem is that plastic, buy when you should pay attention to:1. see, look at the material are impurities.2., smell, if there is a pungent odor, it is recommended not to buy. Attention to drinking hot water, this cup is very bad for the body.

- Q: What kind of glass is smoked glass?

- * basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: What kind of material is the toughened glass film made of mobile phone?

- The low iron glass toughened ultra white suede;To enhance transmittance, a layer of antireflective coating is also applied to the front of the glass

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are two kinds of molding process, high temperature molding (SMC molding) and room temperature molding (hand paste or vacuum assisted molding). SMC molded, there is no problem of glass fiber, hand paste or vacuum assisted molding. If it takes a long time, you will see the bare phenomenon of glass fiber. You can look at the back of his shell, and if you see the surface is not smooth, it should be hand shaped, usually if the car's output is very large, with SMC molding more. My humble opinion. I hope I can help you.

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- When the glass is heated to a suitable temperature, it cools rapidly, causing a sharp contraction of the glass surface and a compressive stress, while the cooling in the middle of the glass is slower and it is too late to shrink, thus forming a tensile stress and making the glass obtain a higher strength. Generally speaking, the higher the cooling intensity, the greater the strength of the glass.

- Q: What kinds of ingredients are the glass?

- Is usually made of sand, sodium carbonate and calcium carbonate eutectic is prepared; also available mixture of sodium sulfate and sodium carbonate to replace carbon melting. Some other glass such as potassium glass, is a relatively high temperature, hard and chemical resistance of glass in molten glass with potassium carbonate to replace sodium or potassium sulfate prepared, mainly used in chemical container manufacturing laboratory commonly used.

- Q: What is the glass industry?

- Heat treatment. By annealing, quenching and other processes, to eliminate or produce glass internal stress, phase separation or crystallization, and change the state of the glass structure, from the process of chemical industry

- Q: What materials are needed for the production of glass bottles and what are their proportions?

- There are many kinds of glass, different kinds, different uses, and different ingredients.

Send your message to us

Clear Float Glass Manufacturer 2-19mm Good Quality Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches