ITO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

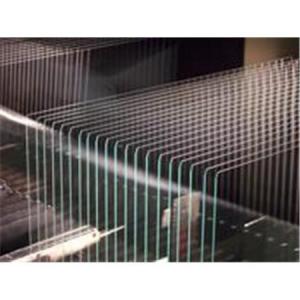

ITO Glass is manufactured through coating ITO transparent conductive layer on single side or double sides of glass according to the advanced technology of vacuum magnetron sputtering. It is the critical material for producing resistive or capacitive touch screens. When used on LCD, a SiO2 layer should be added before coating ITO layer on glass to prevent the ions of glass substrate from penetrating into the conductive layer. If it is requested for higher transmittance, one or multiple AR (anti-reflective) layers can be added before coating ITO layer on glass, thus making it the high-transmittance ITO conductive glass.

Features:

Resistance Uniformity:≤±0.1

Film Thickness Uniformity:≤±0.1

Good adhesive force

Good etching property

Good resistance to acid and alkali

Performance Parameters:

Specifications:

Thickness: 2.0mm; 1.1mm; 0.7mm; 0.55mm; 0.4mm; 0.3mm; etc. (with ±0.05mm tolerance)

Size: 14*14"; 14*16"; 20*24";

355.6*406.4mm; 370*470mm; 400*500mm,450*550mm;550*650mm; etc.

Resistance:

High (150-500Ω) used for ESD protection, Touch Screen control;

Average (60-150Ω) used for TN-LCD, electronic anti-interference;

Low (<60Ω) used for STN-LCD, transparent circuit board, etc.

Applications:

ITO Glass, as a kind of TCO glass, is mainly used to produce display screen, touch screen, mobile phone panel, home appliance panel and others.

ITO Glass used for TN-LCD/HTN-LCD/STN-LCD/TFT-LCD/PDP/OLED/VFD/LCOS in the application of vehicle, consumer electronics, industrial products, LCD (liquid crystal display):

surface resistance: 3.5-100Ω

thickness: 0.4-1.1mm

ITO Glass used for touch screen in the application of mobile phone, displayer, GPS, PDA, instruments and apparatuses, etc.

surface resistance: 150-600Ω

thickness: 0.4-3.0mm

- Q: The use of quartz sand

- Derived from various magmatic rocks, sedimentary rocks and metamorphic rocks, less heavy minerals, associated minerals are feldspar, mica and clay minerals. There are two kinds of sedimentary rock genesis and metamorphic origin, the former is not obvious between clastic particles and cement, and the latter refers to quartz rocks with deep metamorphic and pure quality. The quartz veins are formed by hydrothermal action, almost all of them are composed of quartz, and they are compact and massive structures.The mineral content of quartz sand varies greatly, mainly quartz, followed by feldspar, mica, cuttings, heavy minerals and clay minerals.

- Q: Is glass a recyclable resource?

- Paint raw materials: the use of waste glass and waste tires broken into fine powder, according to a certain proportion into the paint, can replace the coating of silica and other materials.

- Q: Water glass, ceramics, ordinary cement, quartz glass, what are these chemicals?

- The main component of these substances, ceramics, cement, and quartz, is SiO2. In addition, SiO2 is also used to make optical fibers.Elemental silicon is used to make solar panels, chips and other materials

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials of cement clinker clinker production [four main raw materials (limestone, sandstone mainly provides Ca (mainly Si), alumina (or slag, mainly to provide Al (or Fe), iron slag, gypsum, slag etc.)]

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- Ordinary glass plate glass, wire glass and quartz glass (also known as crystal glass) a molding. Wired glass as the quartz glass; only a raw material of sandstone or silica or quartz sand.Tempered glass is made of flat glass as raw material for re processing: the cut of the flat glass into the tempering furnace, heating to about 650 degrees, with cold air quenching, glass forming hardening - tempering. Accomplish!

- Q: The main raw material for the impact of float glass cost?

- About the 70% main components of float glass is silica, the main raw material is corresponding to the sandstone or silica sand (sand), the raw material price level will seriously affect the glass manufacturing cost.

- Q: Is glass fiber reinforced plastic board fireproof partition board?

- A type of fireproof partition board. Glass fiber reinforced plastic sheet is flame retardant and does not support combustion performance. It can be classified into grade a fireproof board in fire prevention and fire fighting.

- Q: Is flat glass the main material or structural component in raw materials?

- But sometimes the structural parts, such as the exhibition hall and the hall, have a transparent floor beneath which the contents are displayed. In order to save the raw materials, they may be designed to be cut from the whole glass without cutting into the box. At this time the flat glass is load-bearing components, to calculate its carrying capacity, which is the structural components of the.

- Q: What are these things that belong to the reactor's raw materials?

- Iron core reactor raw material is similar, more out of the core is made of silicon steel sheet, folder is steel. The lead wires and the wiring bronze are likely to use heat shrinkable sleeves, but this is also available.

- Q: What materials are needed for the production of glass bottles and what are their proportions?

- The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000).

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1984 |

| Annual Output Value | US$ 0.5 Million |

| Main Markets | Mid East; Eastern Europe; North America; Europe; Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese; Korean |

| b) Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ITO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords