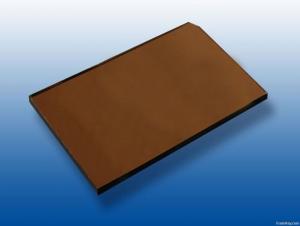

Euro Bronze Tinted Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

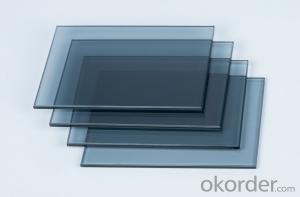

Tinted Glass, also called self colored glass, has possessed low UV transmittance and good shading effects, which are because of its abundant colors and good decorative effects.

Features of Euro Bronze Tinted Float Glass:

1. Diversified Color Series

2. Excellent Product Quality

3.Consistency of color

4. Complete Specifications

5. Continuous aand Stable Supply

Specifications of Euro Bronze Tinted Float Glass:

Thickness: 3-12mm

Size:

Min Size: 920*1016mm

Max Size: 3300*3660mm

customized size

Applications of Euro Bronze Tinted Float Glass:

Tinted Glass is widely used in mirror-making, bathroom, furniture, building, automotive glass and etc.

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Glass: quartz, sodium carbonate, calcium carbonate paper: bark is enough.. cellulose + bleaching agent, such as activated carbon and other detergents, soap bar, sodium stearate

- Q: What kind of glass is alkali free high borosilicate?

- Alkali free borosilicate glass has the characteristics of high surface smoothness, low coefficient of expansion, high temperature resistance, no alkali precipitation and good insulation. Without potassium and nano plasma, it is an important glass raw material for the electronics and Optoelectronics industries. In addition, they do not contain arsenic, antimony, barium, and halides.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Because I work in the glass curtain wall project, only know raw materials to do a glass curtain wall material impact strength test before installing the unit model, in a special laboratory, no experimental requirements should be in the process of construction, the construction of the end of may do some water resistance experiment. Hope to be of help to you!

- Q: The difference between crystal glass and glass

- Feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be. Ordinary glass weight is more self-evident.

- Q: Tile selection, paving process

- Clean up the grass ground, cement mortar, fixed elevation, elastic line, sheet materials choosing, soaking wet, standard for the installation of block, paving cement mortar, paving stone, pouring and cleaning, maintenance and commissioning.

- Q: Aluminum alloy window material is good, how to assemble?

- Glass block: chloroprene rubber, polyethylene and nylon lead block. It is two kinds: the first is to glass and Aluminum Alloy slot and slot bottom metal parts separated by a gap, to ensure control of glass and metal frame relative size effect; second is to prevent the glass due to stretching and metal parts of the collision.

- Q: Tempered and reinforced glass

- Enterprises producing safety glass must pass compulsory certification by the state, otherwise they are not allowed to appear on the market. Therefore, toughened glass has the following signs:Tempered glass, if made into reinforced glass, is substandard products.10mm toughened glass generally costs less than 100 yuan. Paint and not much money, but if the price is higher glaze.

- Q: Is glass fiber reinforced metal material?

- Glass steel (English: Glass Reinforced Plastic, GRP, or Fiber Reinforced Plastic, English: FRP) also known as glass steel or glass fiber reinforced plastic, is a kind of polymer with epoxy resin as matrix, glass steel or carbon fiber reinforced composite material by composite technology and made.

- Q: What is the glass industry?

- To process liquid glass into desired shapes, such as flat plates, various vessels, etc.

- Q: Use of glass flake cement

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale made of C- glass has excellent chemical durability.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Euro Bronze Tinted Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords