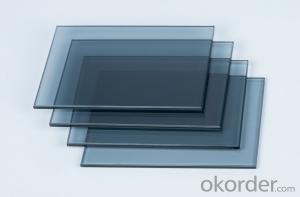

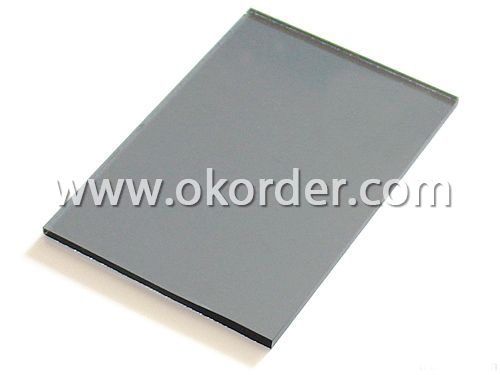

Euro Grey Tinted Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

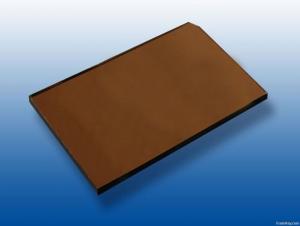

Tinted Glass, also called self colored glass, has possessed low UV transmittance and good shading effects, which are because of its abundant colors and good decorative effects.

Features of Euro Grey Tinted Float Glass:

1. Diversified Color Series

2. Excellent Product Quality

3.Consistency of color

4. Complete Specifications

5. Continuous and Stable Supply

Specifications of Euro Grey Tinted Float Glass:

Thickness: 3-12mm

Size:

Min Size: 920*1016mm

Max Size: 3300*3660mm

customized size

Applications of Euro Grey Tinted Float Glass:

Tinted Glass is widely used in mirror-making, bathroom, furniture, building, automotive glass and etc.

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Organic glass is an important heat, a development of earlier plastic, with transparency, chemical stability and good weathering resistance, easy to dye, easy processing, beautiful appearance, is widely used in the construction industry. The plexiglass product usually can be divided into casting plate, plastic extrusion board and the mold.Acrylic is much more expensive than plexiglass

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so that the hollow {TodayHot} glass gradually eliminated.

- Q: Toughened glass and ordinary glass, process and raw materials what is the difference, a little more detailed, thank you

- Toughened glass is the re processed product of ordinary glass.The main components in the glass is silicon dioxide, calcium oxide and sodium oxide, so called silicate glass. There are two ways to make glass toughened. They are physical tempered (air cooled steel) and chemical steel.Tempered glass adopts a chemical tempering method. The principle is the sodium ion with the "head" the larger potassium ions replace the glass surface "head" is small, so that the glass surface is a state, which is the formation of compressive stress, so that the glass has very high impact resistance (increased by about 5 times).

- Q: What is a hollow glass?

- Hollow glass is composed of two or more pieces of glass, the glass by the internal filling the hollow aluminum isolation desiccant, and the hollow part filled with dry air or inert gas, and sealed with butyl rubber, polysulfide rubber or plastic structure, forming a dry space glass.

- Q: What are the raw materials of glass fiber reinforced plastic?

- It is a kind of composite material made of glass fiber and its products (glass cloth, band, felt, yarn, etc.) as reinforcing material and synthetic resin as base material.

- Q: What does GF30 represent in plastic PP GF30?

- Polypropylene reinforced by glass fiber, mechanical properties, creep resistance and dimensional stability can be improved,.PP-GF30T has a good low-temperature resistance and high impact strength, PP-GF30 heat resistance

- Q: What is the raw material of glass?

- How is glass produced? Glass production process includes batching, melting, forming, annealing and other processes. The following are described below:1. ingredients, according to the design of the material sheet, weighing all kinds of raw materials, mixing in a mixing machine evenly. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.2., melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters, 2.

- Q: There are several ways of heating the industrial drying tunnel furnace and are different from each other?

- The utility model has the advantages of long service life and high reliability. The heater is made of special electric heating material, and the design power load is reasonable, and the heater adopts multiple protection, so that the safety and the service life of the heater are greatly increased.

- Q: What raw materials are used for glass fiber reinforced plastics? Where can I buy them?

- 1, mold silicone rubber: glass fiber reinforced plastic products first need to use the mold silica gel to turn the mold, with the mold can be filled in the mold into other materials. To buy mold silica gel, it is best to directly look for manufacturers, but also to have their own brand trademark of the mold silicone manufacturers, quality and after-sale protection, you can Baidu.2 resin: FRP resin is divided into epoxy resin and unsaturated resin, epoxy resin used less, generally used for high-grade requirements of relatively high glass fiber reinforced plastic products. So we usually use unsaturated resin, and unsaturated resin is divided into #191, #196, #168 several models, #191 quality times, #168 is better unsaturated resin. We can choose different models according to their own requirements. General glass fiber reinforced plastic stores are on sale.

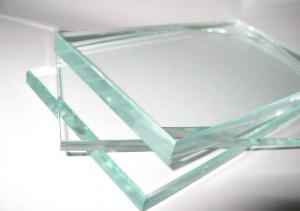

- Q: What are the production processes and raw materials of float glass?

- Float glass production process refers to the glass liquid in molten metal floating on the surface of the flat glass production process. The production process of float glass is to select the raw material needed for the production of glass according to the designed glass composition, and weigh various raw materials according to the designed material, and then prepare the mixture by mixing.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Euro Grey Tinted Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords