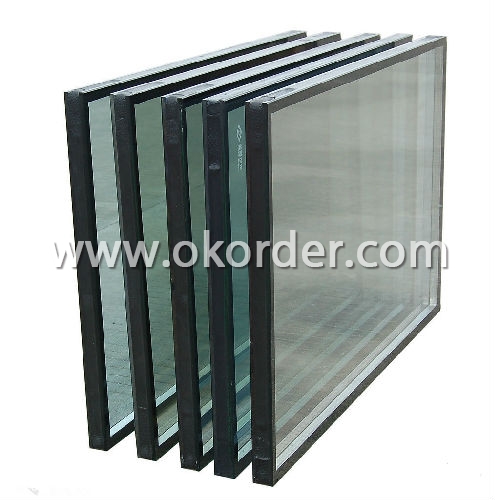

Low-E Coated Glass Single Double Layer Silver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single/Double Silver Low Radiation Coated Glass,energysaving,environmentfriendly, best lighting decorative materials.

Features of Single/Double Silver Low-e Coating Glass:

In winter, silver coatings will reflect heat back to the interior of the building to prevent heat loss; In summer, silver coatings will reduce the re-radiation of heat to make the interior of the building cooler.

solid coatingswill unite with glass into one.

the same lifetime of silver coatings with glass, stable properties, long storage.

easy to process, dispose and store

natural color

no need of special treatment as the layers of insulating glass

conforming to the standard of GB T 18915.2-2008

Specifications of Single/Double Silver Low-e Coating Glass:

biggest size: 3660*2440mm/3660*2134mm (size is subject to customization)

thickness: 4mm,5mm,6mm,8mm

Applications of Single/Double Silver Low-e Coating Glass:

It is widely used in building curtain walls, etc.

- Q: What kind of material is glass made of?

- We know that solid materials can be divided into two categories: organic materials and inorganic materials. Organic materials are wood, plastic, plexiglass, cotton, wool, nylon and so on. Inorganic materials can be divided into three categories: single crystal, polycrystal and glass according to the structure. A single crystal has regular shapes and strict rules, such as the ruby is an alumina single crystal, the crystal is a silica single crystal, and the diamond is a single crystal of carbon. Polycrystal is a collection of large amounts of small single crystals, and all kinds of ceramics and metals are polycrystalline materials. Glass is a noncrystalline solid obtained by melting, cooling, and curing. Its structure has certain rules (short-range order) in the atomic and molecular range, but there is no rule (long-range disorder) in the macroscopic range. It can be made into various shapes by moulds.

- Q: How is glass made? What are the main ingredients?

- Forming。 The processing of liquid glass into desired shapes, such as flat glass, various vessels, etc..

- Q: Is it a vacuum cup with fluorine coating that affects the health?

- Fluorine is a nonmetallic chemical element, chemical symbol F, atomic number 9. Fluorine is the halogen elements of a periodic system of A VII family, located in the second period in the periodic table of elements.

- Q: Why a broken glass film

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: What material can not be sprayed on the glass?

- 1.. First spray the glass and then stick it on the outside with a transparent adhesive tape..2. uses the special printing ink for the glass product, 3. uses the glass glue to adjust the soluble pigment and the dye toner. 4. go to the print shop and do the writing, then glue it on. I hope my answer will be of some help to you

- Q: Comparison of plexiglass steel bridge and inorganic glass steel bridge

- 7, low cost, small fluctuations in raw material prices. 8, heat insulation, sound-absorbing. 9, non combustible. 10, the waste can be used for processing, after smashing the landfill, no pollution to water, soil and air, is an ideal material of environmental protection. Disadvantages of inorganic glass fiber reinforced plastics: 1. Toughness is lower than plexiglass. 2, waterproof performance second only to plexiglass.

- Q: Can ordinary white glass (Bai Jiuping) replace quartz glass?

- Quartz glass is a kind of special industrial technology glass made of silicon dioxide. It is a very good basic material.

- Q: What is acrylic material?

- Acrylic production process;Acrylic sheet according to the production process can be divided into casting and extrusion, better than the properties of casting sheet extrusion, the price is expensive, the plate casting is mainly used for carving, decoration, arts and crafts, extrusion type is usually used for advertising signs, light boxes and other production.

- Q: What materials do you need to make glass?

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- In the sun or under the light, look at the projection, float shadow is very weak, light transmission of good, lattice black lines, one by one

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Low-E Coated Glass Single Double Layer Silver

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches