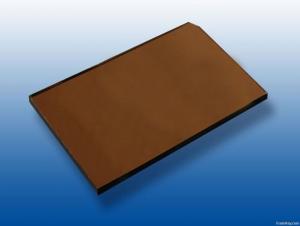

Dark Green Tinted Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

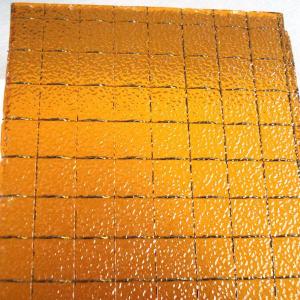

Tinted glass, also called self colored glass, has possessed low UV transmittance and good shading effects, which are because of its abundant colors and good decorative effects.

Features of Dark Green Tinted Float Glass:

1. Diversified Color Series

2. Excellent Product Quality

3.Consistency of color

4. Complete Specifications

5. Continuous aand Stable Supply

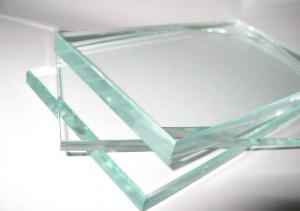

Specifications of Dark Green Tinted Float Glass:

Thickness: 3-12mm

Size:

Min Size: 920*1016mm

Max Size: 3300*3660mm

customized size

Applications of Dark Green Tinted Float Glass:

Tinted Glass is widely used in mirror-making, bathroom, furniture, building, automotive glass and etc.

- Q: Water glass, ceramics, ordinary cement, quartz glass, what are these chemicals?

- The main component of these substances, ceramics, cement, and quartz, is SiO2. In addition, SiO2 is also used to make optical fibers.Elemental silicon is used to make solar panels, chips and other materials

- Q: Ask the glass making processWhat kind of material is the glass made of? What material is good?

- The main raw materials of glass production with glass forming body, glass and other glass intermediate adjustment, as the auxiliary material. The main raw materials, intermediate oxide and oxide to network oxides into the glass forming network; auxiliary materials including clarifying agent, fluxing agent, emulsifying agent, coloring agent, bleaching agent, oxidant and reductant.

- Q: What are the raw materials for making glass?

- The main raw material for making glass is sand, its main component is silica, which is commonly called quartz.

- Q: What is the ratio of raw materials for glass mildew proof powder?

- Features: using high-quality coconut shell as raw materials, by crushing, mixing, extrusion, drying, modification and so on;R & D institutions: Department of chemical and chemical engineering of Nanjing University, GREE R & D institutions, Department of environmental science, Nanjing University, Jiangsu physical and chemical testing center;Advanced: for the domestic initiative, greatly solved the domestic construction materials, such as glass mildew problems, environmental protection is good, in line with Europe and the United States and other countries

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- The main raw material of silicon dioxide, the price is related to the quality

- Q: What is the raw material of glass glue?

- The common glass glue equipment are as follows: 1.JMSFYF stainless steel reactor series production 2.JMSNHZ series of glass glue silicone kneading machine series 3.JMSXJB planetary mixer series 4.JMSQLF series 5.JMSDLH series strong dispersion mixer hybrid machine series mainly plastic equipment.

- Q: What raw materials are used for glass fiber reinforced plastics? Where can I buy them?

- Promoter: resin special accelerator is also added in proportion, the general resin manufacturers will also support the production. General glass fiber reinforced plastic stores are on sale.

- Q: What is the density of glass flake cement?

- Glass flake is an important raw material for producing heavy anti-corrosion coatings, pearlescent pigments and plastic products indispensable, used in anti-corrosion field, can significantly improve the anticorrosive performance of the coatings, prolong the service life of the object; used in the manufacture of glass flake pearlescent pigment, pearlescent pigment luster far better than natural mica, synthetic mica pearlescent pigment production, and has antiseptic and anti ultraviolet function; used in plastics industry, plastic products can increase the strength, prevent thermoplastic plastic precision parts made of thermal deformation, improve the stability of space.

- Q: What is the glass industry?

- To process liquid glass into desired shapes, such as flat plates, various vessels, etc.

- Q: What are the construction principles and raw materials of tempered glass?

- Tempered glass, also called toughened glass, is a kind of prestressed glass. It uses physical or chemical methods to form a compressive stress layer on the surface of glass. The glass itself has a higher compressive strength and will not cause damage. When the glass is subjected to external force, the pressure layer may be part of the tensile stress offset, avoid broken glass, although tempered glass is in large internal stress state, but the glass no internal defects, without causing damage, so as to achieve the purpose of improving the strength of glass. It is well known that microcracks on the surface of materials are the main causes of material rupture. Because the microcrack will expand gradually under the action of tension, and finally crack along the crack. And because of the large compressive stress on the surface of the glass, the microcracks on the glass surface become more fine and even heal under the action of extrusion".

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Dark Green Tinted Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords