Corrugated Sidewall Conveyor Belt

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

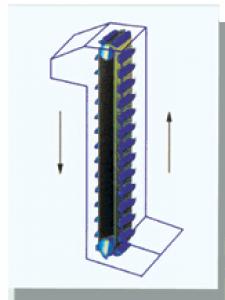

In some conditions, due to the limit space or in case of lifting materials at a large slope, sidewall conveyor belt is always used to avoid material spilling. This system can convey materials vertically and also can work at a large slope from 0 degree to 90 degree, and allow heavy load material conveying.

Application: harbor, metallurgy, mining, electricity, coal, foundries, construction, food, cement works, fertilizer, etc.

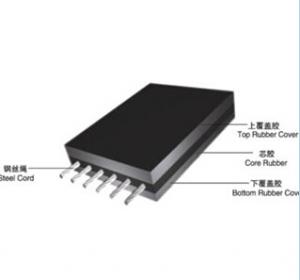

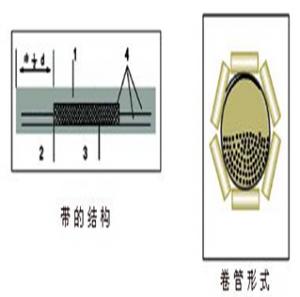

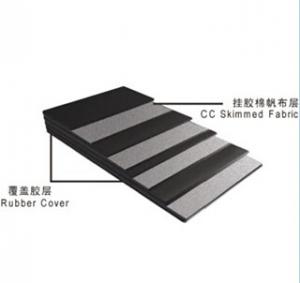

Carcass: the carcass of the base belt can be CC, NN and EP fabric.

product feature:

1. low maintenance cost;

2. Large transport capacity, and it can avoid material spilling effetely ; 3. The belt can facilitate switching from horizontal to inclined conveying from inclined to horizontal conveying ;

4. It saves a lot space as it allows material conveying at 0°-90°.

- Q: Why are the engines almost all rubber belts?

- The use of rubber belts also has a role in ensuring the safety of the transmission equipment, such as wheels, bearings and engines, and is easy to change and cheap.

- Q: Conveyor rubber belt welding

- The belt of belt conveyor consists of reinforcing material (core), core material (adhesive), covering rubber and adhesive. Delivery method with connection mechanical connection method, cold glue connection method, heat curing connection method three kinds, including mechanical connection and cold glue connection method is only applicable to fabric conveyor belt, heat curing connection method is suitable for all kinds of rubber conveyor belt.

- Q: What sectors does rubber drive? That is to say, what are the main uses of rubber?

- There are many kinds of rubber, depending on what kind of rubber, each kind of rubber has its own use, can not be generalized.

- Q: What's the rubber band on your wrist when you play basketball?

- It means the player's message strip, usually with the name of the player, the team and the number, but we are not professional players, so take that as a decoration

- Q: How many layers of rubber band are glued together?

- Plain belt(with high strength nylon conveyor) products perform GB7984-2001 standards.Cover: the tensile strength of not less than 15Mpa, tensile elongation of not less than 350%, the wear is less than 200mm3, bonding strength between the layers is not less than the average value of the longitudinal 3.2N/mm layers of cloth, cover rubber and cloth layer is not less than 2.1 N/mmFull thickness longitudinal elongation of not less than 10%, the thickness of longitudinal reference force elongation is not greater than 1.5%

- Q: How to distinguish sanlux rubber belt quality

- The fixed belt conveyor adopts a fixed bracket, and usually the outer end of the roller on both sides of the groove support roller is deflected from the direction of the conveyer belt to form an angle. In this way, because of the existence of the idler angle, the lateral roller has a certain lateral thrust on the running belt. When the belt is in its normal position, the thrust force on both sides is equal in magnitude and opposite in direction. Once the deviation, deviationThe lateral thrust of the side is greater than the other side, and the belt is restored to its normal position under such lateral thrust. It must be pointed out that the relative slip between the belt and the deflection roller will lead to wear of the conveyor belt. Therefore, the angle of the side roller can not be too large, generally 2 3?. Therefore, this method is only effective for the condition of little deviation.

- Q: What should I pay attention to when the belt conveyor is setting the brake?

- Safety shutdown of transport and transport equipment downtime or velocity is close to zero the braking action, will effectively avoid the transportation industry with the decline, due to the use of backstop in transport machine, so we must set the brake on the transport belt conveyor can be quickly set up efficient backstop or brake;

- Q: White rubber strap dirty, how to do?

- First, fold the film and magazine together, then roll them together into a cylinder, which prevents the book from wetting the strap while cleaning the strap.Then put the watch on the roll of the cylinder. Zoom in on the magazine roll until the watch band is fully extended and the watch won't fall off. In this way, on the one hand, it is convenient for cleaning in a while, and more importantly, after opening the watchband, the stains at the slit of the watchband can be cleaned.

- Q: What do you call a machine that folds rubber bands into a stamp?

- The word "mechanical" in modern Chinese is the generic term for "Mechanism" and "machine" (Machine). Mechanical features are: machinery is a combination of artificial physical components. A definite relative motion between the parts of a machine. So the machine can convert mechanical energy or perform useful mechanical power, is the modern mechanical principle in the basic concept, the modern concept of multi-source Chinese mechanical word from the Japanese "machinery", Japan's machinery products do the following definition of mechanical concept (that is consistent with the following three features called Machine).

- Q: What are the advantages of natural rubber?

- Natural rubber (abbreviation: NR, English Name: Natural Rubber)Usually smoked rubber, crepe, dry glue, glue... Etc.. The dry glue without smoke and natural rubber, color to dry shallow, suitable for light and color productsThe macromolecular structure unit of natural rubber is isoprene, and the macromolecular chain is mainly composed of CIS -1, 4 polyisoprene. NR is one of the best synthetic properties of all rubber in mechanical and processability.

Send your message to us

Corrugated Sidewall Conveyor Belt

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords