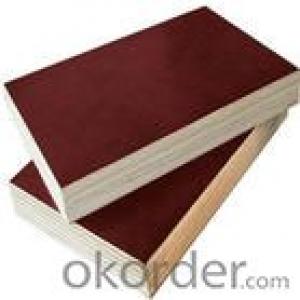

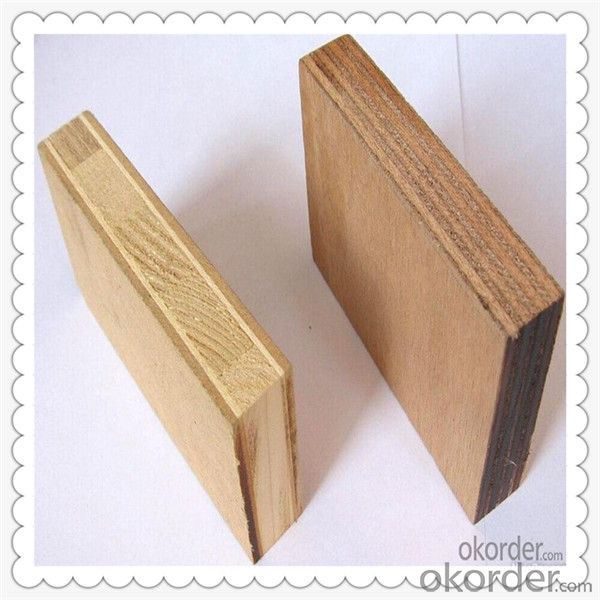

Commercial Plywood with High Quality for 15mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commercial Plywood with High Quality for 15mm Thickness

Product Description:

· Type: Plywood

· Material: Wood

· Panel Type: Commercial Plywood

· Use: Outdoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

· Material: Poplar Material

· Thickness: 3mm to 21mm

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- Energy-saving insulation: thermal insulation superior performance, the same thickness of the insulation effect is 2 times the EPS board. ? Flame retardant: The product has passed the "National Fixed Fire Extinguishing System and Refractory Component Quality Supervision Center", the combustion level to GB8624 B2 level standards. ? Sound insulation: sound absorption is good, on the rain, hail and other impact caused by the sound has a subtractive effect. ? Waterproof rust: a large span, fast drainage, waterproof effect is good; screw hidden, easy to rust, to extend the useful life of the plate. ? Beautiful economy: beautiful appearance, rich colors; reduce material loss, save construction time and project costs. ? Construction of fast: polyurethane sheet is a highly controlled plant in the factory environment, the quality of production, quality and stability; construction fast, the application has more than 35 years.

- Q: Why do you want to use polyurethane seal on both sides of the multi-dimensional joint group of OKorder Yanmian sandwich panels

- As a new type of rock wool sandwich panels, his plate is a dark buckle is not nails, so that the board on both sides of the plug interface into the opposite sex, and in the production process sent by the rock wool is equal thickness, which makes The mouth and the mouth of the mouth of the cotton-free cavity, and the subsequent manual joints, but also produce cotton and steel plate bonding performance is poor, anti-stripping poor, this result will be cold in the winter, summer will produce heat Bridge, the more serious is in the wall board, bear the load object entirely by the self-tapping to bear, and because the rock wool sandwich panel is horizontal installation, and its two sides of the plug interface becomes the upper and lower parts, and its Is empty, so that the rock wool is completely attached to the steel by glue, a long time, rock wool fall, resulting in deformation

- Q: 100 thick composite sandwich board how much money a square meter upper plate 0.6 lower 0.4

- More than sixty yuan / square meters ---- ordinary materials.

- Q: Industrial building facades

- Even the United States outside the wall panels, search Dalian, the official website of the United States chemical building materials.

- Q: Domestic manufacturers of rock wool sandwich panel machine which quality is better? What is the price in general?

- My company is using OKorder Yongming, spent more than six years. I personally feel that quality can be. My friend is using the other manufacturers in OKorder, you can also use, the domestic manufacturers in OKorder is doing a little better. As for the price, a price of a cargo, the landlord can visit more, the domestic production of such equipment manufacturers concentrated in OKorder and Hebei.

- Q: The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q: So here's the deal, I really need to run the oven cleaner, and I know how much smoke will come out of the oven, and I have a wired smoke alarm directly above the stove (landlord's design not mine). If I cover it with a sandwich bag, will that slow down the chance of it going off or increase the chance? Yes I know to remove the bag directly after the oven cleaner is done for obvious saftey reasons.

- it should slow it down

- Q: I have a small shed, want to use sandwich panels construction, how can the summer 40 degrees with air conditioning to save power

- Wall plug a layer of sandwich panels no problem, but the window and sandwich panels to achieve the same insulation effect is difficult!

- Q: How to fix the color steel tile foam sandwich panel

- Color steel foam sandwich panels are generally lap type. And then with self-tapping fixed, very simple. Botou Shengda pressure tile Machinery Plant

- Q: The steel roof and the sandwich panel are waterproof

- The two are actually the same class of things, sandwich panels only the color plate and insulation layer together, the installation more convenient. And the pressure steel roof need to lay another insulation layer and the roof. For both, the weak links of water are between the plates. In the actual project, the seam of the steel plate roof can be made in many forms, some of the overlapping form of waterproof performance is very good, and the common sandwich board roof shape is relatively simple, so the waterproof performance is also worse.

Send your message to us

Commercial Plywood with High Quality for 15mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords