Prefabricated Wall Panels from CNBM China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

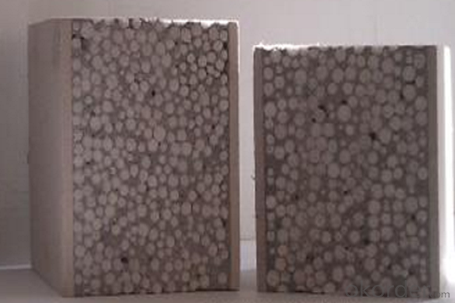

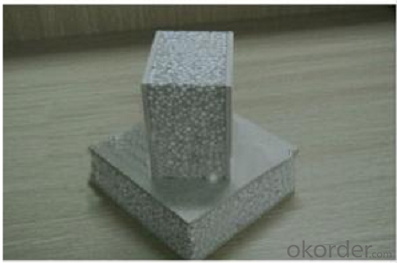

Composition: EPS+cement+calcium silicate board

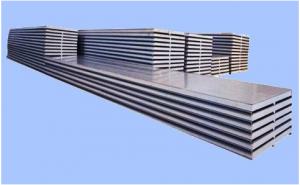

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

JY wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Project

Certificate

Q1: How soon can we receive the goods after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service?

A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Polyurethane sandwich panel production line which part of the composition, where the polyurethane sandwich panel production line is better?

- Polyurethane composite insulation board production line complete sets of equipment, mainly by the open system, film cutting system, forming machine system, steel preheating furnace, high pressure foaming system, double track system, double track heating system, cutting system, horizontal cooling system, palletizing Systems, packaging systems and a series of equipment. Zhongji Machinery Manufacturing Co., Ltd. was established in 1992, won the title of national high-tech enterprises, and the Ministry of Commerce was identified as designated equipment export manufacturers. But the price is more expensive!

- Q: How to install the cold sandwich sandwich sandwich panels

- If the use of polyurethane cold storage board, then use the structure of the installation of the installation time can be reported to us can also install their own This is a drawing in accordance with the drawings can be installed

- Q: Color steel sandwich panel wall, you can directly spray really stone paint what is the practice

- According to the following construction methods to achieve good results: 1, in the sandwich panel (plate) on the gap to be caulking. It is recommended to use the home of the heart of the card to worry about toughness to fill the joints, and then paste the seam (master understand). 2, if directly in the sandwich panel (plate) on the batch of putty powder or spray paint really easy to drop off the phenomenon of paint, the first primer, it is recommended to use the home of the board of people worry-free putty scraping again There are), to be dry and then approved scraping putty powder. 3, spray really stone paint.

- Q: How do the polyurethane sandwich panels be PIR or PUR separately?

- PIR composite sheet refers to the polyurethane foam as a core commonly used is the polyester polyol, high isocyanate index (250 or more), with or without the use of flame retardant formulations, the foam skeleton structure is from the carbamate Chain and carbamate modified isocyanurate segments, the product can be used at below 150 degrees Celsius.

- Q: Color plate and color steel sandwich panel difference

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: The use of foam sandwich panels erection of the temporary board of the building components of the combustion than the A-level, to rectification, how to engage in ah

- Foam sandwich board where are lower than the A-level, but still someone use, because the convenience, the price is low, so let you rectification is to let you ask you to pay for it

- Q: Thickness of rock plate sandwich panels Drawings are written on the F50 color steel rock wool sandwich panels, I would like to ask F50 is the meaning of God, can represent the thickness of it? I asked whether the F50 can represent the thickness of 50 or just a model, in fact, the thickness of 100?

- I have a solution to it. F that Fire, should be the brand is Lokewei it, because Lokowei have 50F and 50C, there are 75F and 75C models, F is the fire board, C said the ordinary version, but 50 can not represent the thickness, because our Offer range, 50F and 50C have 50,80,100,120 mm ... and so the thickness, so 50 can not be the thickness of the thickness of the need for additional set. PS: 50 in Lokovo and intensity (density) have a relationship .50 strength is not high strength of 75. The higher the thickness the thicker the thickness

- Q: What are the key notes when buying a rock wool sandwich panel?

- 1. Slag content; slag content determines the quality of rock wool. High-quality rock wool is made from basalt or diabase, while poor quality rock wool is mixed with blast furnace slag or other metallurgical slag. In contrast, the slag content is low and the acidity is low Poor, with the temperature changes will greatly accelerate the fiber fracture and powder, thus losing strength and insulation properties. So, will become a building hazard. 2. Fiber average diameter; national standard is ≤ 7μm. The new rock wool fiber-forming process combined with the basalt material itself makes the rock wool fiber slender and flexible, the fiber diameter can be stabilized at 4-7μm; the pendulum method and the multi-dimensional pleating technique make the distribution of the Yanmian fiber evenly and in three dimensions Chaos, greatly improving the density and strength of rock wool. 3. Thermal conductivity; high quality rockwool slag ball content is low, fiber diameter is moderate, the use of pendulum method of production technology, fiber distribution, uniform direction, bulk density uniformity, low thermal conductivity. Poor rock wool is the opposite. Usually slag cotton using sedimentation chamber production process, low thermal conductivity

- Q: What is the thickness of the upper and lower panels of the rock wool sandwich panel? Is there any provision in national standard?

- 1. Upper / lower steel plate thickness: 0.25 ~ 0.8mm color steel / electric, hot galvanized sheet / stainless steel plate 2. Core material: (mine) rock wool capacity of 120 ~ 150kg / m 3. Side seal steel strip or no side seal steel strip: 0.4mm ~ 0.8mm galvanized sheet 【Product Specifications】 1. Effective width of the mouth: 950mm, 1150mm; thickness of 40mm ~ 150mm; length is not limited 2. Board protection form: complex PVC protective film 【Product Features】 1. Advantages: good fire resistance, sound insulation better. 2. Disadvantages: strength is not good enough. 3. Fire rating: Class A

- Q: What is the difference between the board and the core board?

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than ... but generally do not choose the best! Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, ... plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement. The outermost front panel is called a panel, and the back is called a backplane. The inner board is called the core plate.

Send your message to us

Prefabricated Wall Panels from CNBM China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords