EP Conveyor Belt/NN Conveyor Belt/CC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EP Conveyor Belt/NN Conveyor Belt/CC Conveyor Belt

Description of Rubber Conveyor Belt

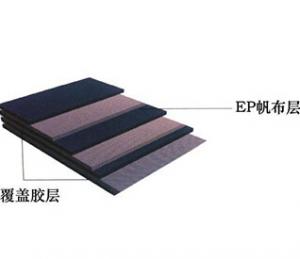

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildewproof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

cc conveyor belt/nn conveyor belt/ep conveyor belt Features:

1. increases the transmission angle (30 ~ 90 degrees);

2. covers an area of small, low investment;

3, throughput, and enhance the high degree of higher

4. from level to tilt (or vertical) will make a smooth transition;

5.Low elongation

6. suitable or easy transportation of powder, granular, small block, paste and liquid-like materials

7. low energy consumption, simple structure, high strength tape, long service life.

8. Heat-resistant

9. Oil resistant

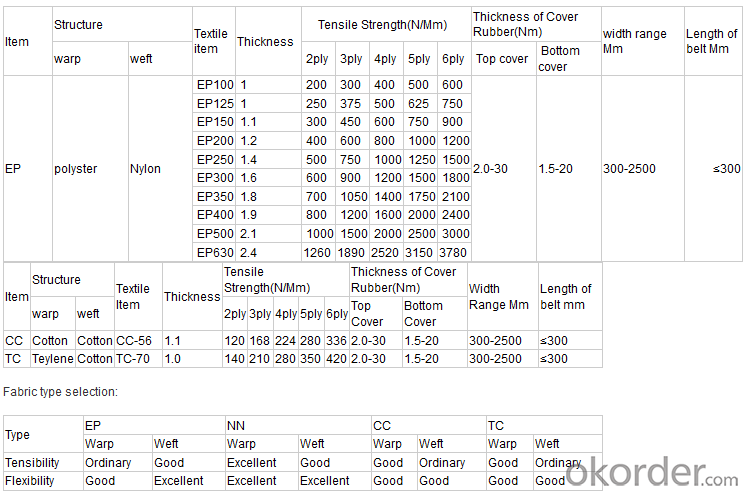

Specifications of Conveyor Belt

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q: What are the rubber parts for the car?

- Sealing ring, toothed cutting belt, automobile synchronous belt, automobile multi wedge belt, automobile engine suspension rubber pad, shock absorber glue, anti-collision shock absorption rubber, dustproof cover, fuel tank cover, filter rubber parts, cloth (diaphragm)

- Q: Advantages and disadvantages of rubber products

- Ding Ji rubber II R(Butyl Rubber) and a small amount of isobutylene isoprene polymerization and, due to steric hindrance of the methyl group than other molecular motion of polymers, so the gas permeability less, resistance to heat, sunlight, ozone, electrical insulation resistance; the polarity of solvent resistance, general use temperature range of -54-110 degrees. Advantages: for most of the general gas with permeability, resistance to sunlight and smell good to be exposed to animal or vegetable oil or chemical gasifiable in. Disadvantages: do not recommend the use of petroleum solvent, rubber, kerosene and aromatic hydrogen, used in automotive tires tube, leather, rubber paper, window frames, rubber, steam hose, heat conveyor belt and so on.

- Q: What kinds of vulcanized rubber do you have?

- According to the appearance of rubber: rubber can be divided into solid rubber (also known as dry rubber), emulsion rubber (referred to as latex), liquid rubber and powder rubber four categories.

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- HNBR has a high temperature resistance of 130~180 degrees, cold resistance of -55 ~ -38 degrees, and good mechanical properties, compared with other polymers, can meet the requirements of the automotive industry. HNBR with ZnO/ methacrylate (MAA) can be used to make V-belt, triangular V-belt, multi base rubber, vibration isolator and so on. It can also prepare sealing ring, sealing element, heat resisting tube and so on. In oil drilling, rubber products are required to withstand high temperature, high pressure, acid, amines, H2S, CO2, CH4 and other tests of steam. The products prepared by HNBR can be acid resistant, oil resistant and solvent resistant. With the ZnO/MAA HNBR reinforcement can be used for the production of drilling mud pump piston and protection box. In addition, the beating method HNBR can be used as a sealing washer washer made of paper oil industry and automobile industry. HNBR heat and radiation resistance properties than silicon rubber, fluorine rubber, poly four vinyl chloride is better, suitable for all kinds of rubber seals for power station, is also used as a hydraulic pipe, hydraulic seals, power station for cable sheath, can also be used for printing and fabric roller, weapons components and aerospace seals, cover, fuel capsule; HNBR latex can be used as a surface coating (painting), textile, paper, leather, metal, ceramic fiber, non-woven adhesive, and foam rubber, latex impregnated products etc.. In addition, with ZnO/MAA, peroxide and high wear furnace HNBR, its comprehensive performance is better than ordinary HNBR.

- Q: How long does the rubber last?

- Depends on what kind of rubber material, each material's aging resistance is not the same

- Q: How to identify the tire rubber is raw or cooked

- Rubber is a kind of polymer material with high elasticity, is the parent material manufacturing of rubber products, generally refers to the rubber unvulcanized. A nearly neutral liquid produced by a rubber tree and added with 0.05%~0.1% ammonia water to make latex (for a short period of time). Most of the latex need processed dry glue, all kinds of natural rubber is often said.

- Q: What is rubber made of?

- Early rubber was made from latex of rubber trees, rubber grass and other materials made of flexible, insulating, impermeable and air.

- Q: What are the reasons for rubber cracking after shock absorption of rubber products?

- Shock absorber rubber suspension products, durable rubber cracking:1, rubber aging, weathering, heat resistance;

- Q: How to improve the aging resistance of rubber?

- Whether it is rubber, rubber or rubber particles have a certain life, want to extend the service life of rubber and related products, we must first understand what factors affect the aging speed of rubber products, the four main factors affecting the aging of rubber particles for oxygen, ozone, heat and light.Oxygen oxidation by the rubber molecules of free radical chain reaction, molecular chain fracture or excessive crosslinking, cause the rubber properties changes.

- Q: There is a crack in rubber products

- It is possible that the sulfur is too fast, the outside is ripe and the inside is slow cooked because of the uneven expansion

Send your message to us

EP Conveyor Belt/NN Conveyor Belt/CC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords