calcium silicate board --- Exterior Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

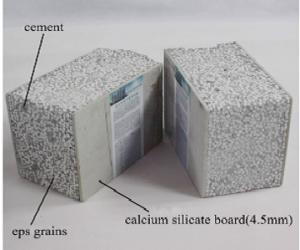

Composition: EPS+cement+calcium silicate board

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

Our wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Project

Certificate

Q1: How soon can we receive the goods after purchase? A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service? A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: There is a phone call

- The price of polyurethane sandwich panels have the thickness of the polyurethane sandwich panels used and the color and thickness of the color steel plate to determine the price of its polyurethane sandwich panels. The common polyurethane sandwich panel specifications are 50,75,100,150,200 thick Of the price between 90-120 yuan. Manufacturers can see my picture, you need the above contact information. Here to tell you degree mother and give me a shield, and I easily I, to high score ah!

- Q: How to calculate the amount of steel wool sandwich panel

- According to the top area.

- Q: Cold storage installation sandwich panels need to use sealant? With much more, with polyurethane sealant or silicone glue more?

- Generally with porcelain white neutral silicone

- Q: EPS sandwich panel metal panel thickness requirements

- The state requires more than 0.5MM, but now the market have to do more thick. The The But also the agreement between the two sides.

- Q: Activity board room C-shaped steel and Caigang sandwich panel is how to connect the seal?

- This is the plug without sealing if you need to seal and then plug the sealant on the line

- Q: Rock wool sandwich board standards which

- Rock wool core material: the use of density of 120kg / m? rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness.

- Q: I need to install a circuit breaker and a few outlets on a container made with sandwich panels.Are there any special equipments or materials for the job?

- This is a tough one. You may have to use 2X4's to extend the wall inwards to allow for it. I attached a link that might help.

- Q: Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- Normal concrete beam span of not more than 5 meters, or the volume of the beam to do very exaggerated. So use a lightweight architecture It is understood that foreign general steel truss girder, but also useful wood beams under the steel truss.

- Q: To do color steel sandwich panels.

- Now is the best in Sichuan

- Q: Color steel sandwich panels, foam and rock wool, the two materials that material to do the insulation effect of the core material better

- Simply from the insulation effect is certainly a bubble But it is better for rock wool from safety and fire resistance

Send your message to us

calcium silicate board --- Exterior Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords