Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: |

Specifications

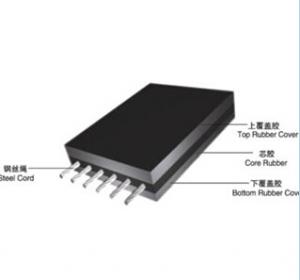

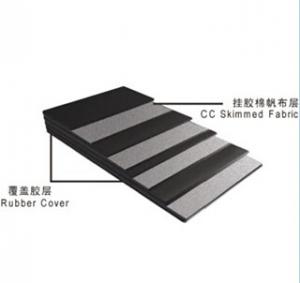

EP conveyor belt,NN conveyor belt, Steel cord conveyor belt, Flame retardant conveyor belt,Rubber V belt, Raw edge cogged v belt

WHAT WE OFFER:

Various product includes: EP conveyor belt,NN conveyor belt, Steel cord conveyor belt, Flame retardant conveyor belt, High temperature resistant conveyor belt, Chevron conveyor belt, Cold resistant conveyor belt, Rubber V belt, Raw edge cogged v belt, Banded v belt, Agricultural v belt, Motor v belt, Variable speed v belt, etc. Customized service can be offered any time.

Sales capability: Over $60million annually

Testing capability: Our technical labs have always been upgrading for testing the physical, chemical, and component properties of materials and finished product.

Primary exporting market: U.S., Canada, UK, Brazil, South Africa, Mid-east, and Russia, etc

Maintenance and warranty service offered.

WHAT PRINCIPLE WE STICK TO:

Survive on Quality, Benefit from Management, Develop by High-tech.

- Q: What are the main failure modes of belt drives?

- The main failure modes of belt drive are skid and fatigue failure.1, with fatigue fracture:The stresses on any cross section of the band will change as the belt moves. When the stress cycle reached a certain number, that is, after running for a certain period of time, the belt appeared in the local fatigue crack delamination, and then appeared loose or even fracture, resulting in fatigue damage, loss of transmission capacity.

- Q: I answer, is always jumping with a triangular CVT wheel and engine of the key, I see some triangle turn like, how do I like, freely flowing style of writing, tune ah, or what is bad?

- This is normal, this does not use for a period of time to back this way, V-belt loose,

- Q: What are the five failure modes of gear wheel drive?

- The most important part of gear is the gear tooth. There are four main forms of its failure: tooth break, tooth surface wear, tooth surface pitting and scuffing of tooth surface1. broken teethBecause the stress on the tooth root is the greatest, and there is stress concentration, therefore, the fracture of the gear tooth usually occurs at the root of the toothIf the tooth unilateral work, root bending stress is tensile, the other side is compressed, the tooth is disengaged, the bending stress is zero. Therefore, in the repeated load, the bending stress exceeds the bending endurance limit, the root part will cause fatigue cracks. The crack gradually expand, will eventually cause the broken broken teeth, known as fatigue fracture.The sudden fracture of the gear due to short time overload or impact overload is called overload breaking. This kind of gear is easily broken by gears made of brittle materials such as hardened steel or cast iron

- Q: How do you calculate the torque of the belt?The structure of the design is shown in the figure,

- The shaft is a steel shaft with a solid diameter of 200. The outer ring is made of crimped material. The fabric density is 1.1, and the maximum crimp diameter is 1800

- Q: Classification of industrial belts? FiveI hope you can point out in detail

- The driving belt is the power that rotates the motor or the engine of the prime mover, and is transmitted by belt to the mechanical equipment through the pulley, so it is also called the power belt. It is the core of mechanical and electrical equipment coupling components, a wide range of types, very wide range of uses.

- Q: How do I remove the air-conditioning compressor and the engine belt?

- Remove the refrigerant pipe under the belt and air conditioning compressor.

- Q: What are the consequences of the broken fan belt?

- Emergency treatment is to tie the broken belt with a fine wire, continue low speed, or use a "stop" approach to drive the car away, the driving process should pay attention to the temperature of the instrument panel. When the above measures fail, a rescue call must be called for rescue.

- Q: The scooter does not catch fire after changing the belt

- Just happen to change the belt, it is recommended to check the spark plug, high voltage, air filter, carburetor, wiring and so on, whether there is a problem.

- Q: HelloCould you explain to me what the belt is? What is the weight per square meter? Does the thickness have a standard? What do you mean by 28, 32, 36?

- The driving belt is the power that rotates the motor or the engine of the prime mover, and is transmitted by belt to the mechanical equipment through the pulley, so it is also called the power belt. It is the core of mechanical and electrical equipment coupling components, a wide range of types, very wide range of uses. From large to several thousand kilowatts of giant motors, small to less than a kilowatt of micro motors, and even appliances, computers, robots and other precision machinery, are inseparable from the drive belt. Its biggest characteristic is that it can change speed freely and drive near and far. It is simple in structure and convenient to change. Therefore, from the primitive machine to the modern automatic equipment, there are transmission belt figure, the product has undergone many changes, technology matures.

- Q: Is the driving belt of the dynamic bike good or good for the belt?

- Introduction to chain drive:?Advantages: relatively strong, durable, in the process of transmission of power, the power loss is small, not easy to bad!?Disadvantages: there is noise, timing also need to add lubricating oil, maintenance cost is higher!

Send your message to us

Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords