Textile Carcass Conveyor Belt

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Heat Retardent Textile Carcass Conveyor Belt

1.higher stength

2.longer work life

3.low elongation

Heat Retardent Textile Carcass Conveyor Belt

Market: Cement, Foundry, Iron Ore, Steel Production.

Applications: Cement Clinker, Coke Plants, Hot Power Materials, Sintered Ore, Steel Mills, Taconite Pellets.

Tensile strength: 500~8000N/mm

Features & Benefits:

1,Heat-resistant cover resists cracking and hardening

heat-resistant belt performs over the long run, retaining its flexibility despite punishing condition and loads. Less cracking and hardening translates into longer life and reduced replacement costs. Heat-resistant belt compound retains its Heat-resistant qualities after prolonged exposure to 200°C hot loads.

2,High-temperature resistance to tearing and abrasion.

Load after load, Shandong aneng belt stands up to prolonged exposure. This reduced maintenance and downtime helps lower overall operating costs.

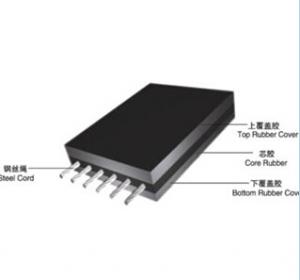

3,High strength carcass construction

use steel wire or synthetic material. Synthetic carcass provides great dimensional stability and strength at high temperatures and operating tensions up to 2000 kN/mm.

4,The carcass with heat-resistant material

apply special carcass in the heat-resistant belt, provide maximum protection when temperatures are not constant. The carcass stand up to “hot shots”, resisting burn-through up to 538°C.

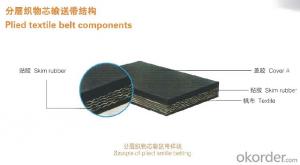

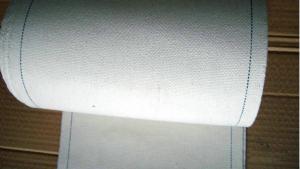

The belt carcass of this product is EP fabric of high modulus,low shrink,and high breaking tensile strength.Cover rubber of this product uses EPDM rubber or Chloro-butyl rubber that has very good high temperature resistance.the belt is made with extra care after mixing rubber with high temperature resistant materials,assembling and vulcanizing.

The carcass of this priduct has very high adhesion after the special treatment of coating and shaping.Under normal working temperature of below 180°C,the belt is low in elongation,excellent in anti-abrasion,and can bear 250°Chigh temperature for a short time.The belt is suitble foe use in cement,metallurgical and steel industry.

It can be divided into four types according to working temperature range:

Type | Operation temperature | Max operating temperature of short-term |

T1 | ≤100°C | 120°C |

T2 | ≤125°C | 145°C |

T3 | ≤150°C | 170°C |

T4 | ≤175°C | 200°C |

The specification and main parameters

Strength of full-thickness longitudinal tensile(N/mm) | Fabric type | Thickness of top cover(mm) | Thickness of bottom cover mm | Number of fabric plies | Quality of single fabric sheet (kg/m2) |

200-800 | EP100 | 3.0 4.5 6.0 | 1.5 3.0 | 2-8 | 1.3 |

315-1250 | EP150 | 3.0 4.5 6.0 | 1.5 3.0 | 2-8 | 1.4 |

400-1500 | EP200 | 3.0 4.5 6.0 | 1.5 3.0 | 2-8 | 1.5 |

500-2000 | EP250 | 3.0 4.5 6.0 | 1.5 3.0 | 2-8 | 1.7 |

500-2000 | EP300 | 3.0 4.5 6.0 | 1.5 3.0 | 2-8 | 1.8 |

630-2500 | EP400 | 3.0 4.5 6.0 | 1.5 3.0 | 2-7 | 2.1 |

- Q: Why is the watch of rubber band more expensive than resin?

- PS: rubber contains a variety of ingredients, a pungent odor, some of which may have an impact on human health, so generally contact the skin and long-term contact will use silicone.

- Q: How do you remove the gasoline from the rubber band?

- Hardware store, where you can buy paint, 5 dollars a small bottle. Give in cloth, repeatedly rub, rub a few will be able to erase. Tips: hand in a plastic bag, or to buy the duck to several gloves, don't get thinner on the hand, will corrode the skin.

- Q: Why are the engines almost all rubber belts?

- All kinds of driving methods have their own advantages and disadvantages.Sprocket, chain drive - transfer speed is limited.Gear transmission --- the transmission distance is limited and the noise is great.Belt drive - smooth transmission, quiet, easy to implement, low cost.

- Q: How do I remove traces on the rubber band?

- Try to smear the dirt on the surface with toothpaste because the toothpaste has a lot of friction against the object

- Q: What's the rubber band on your wrist when you play basketball?

- Theoretically, it prevents perspiration, prevents sweat from flowing down the arm, makes the hands slip and throws the ball

- Q: The difference between roller printing machine and rotary screen printing machine

- The 2 processes are continuous printing, faster than the speed of roller printing; in fine pattern is by fine carving to decide on it from the theoretical precision can reach 20 micron, also reflected in the actual production, but the rotary screen printing precision is by nickel mesh fineness (mesh) to decide on the current market maturity, below 155 mesh is more reasonable;

- Q: How to distinguish sanlux rubber belt quality

- Belt conveyor belt conveyor is the most common fault, if not handled in a timely manner, and belt conveyor, conveyor belt and the frame will lead to intense friction, the conveyor belt edge is napping and even tear, not only affect the life of the conveyor belt, but also easy to spread, the influence of cultural production. When the conveyor belt from the serious deformation of roller and fall, cause downtime accident, therefore, the belt conveyor installation, debugging, operation and maintenance work should be paid special attention to the operating state of the conveyor belt, to prevent the belt deviation caused by the accident

- Q: How to clean rubber band?

- 1. Soak it in hot water for a while, then you can peel it off.2, use the hair dryer blow, the glue baking heat can be got down.3, with Fengyoujing rub, then try out.4, you can try a rubber. But in the beginning, you may think the more you rub the dirt, but the longer the rub, you will see the effect, this method is relatively tired, have perseverance.5, with blisters, put a little detergent, and then use an old toothbrush to brush.6, with a cloth with alcohol or Erguotou wipe it.

- Q: What are the advantages of natural rubber?

- Major performance characteristics:Advantages: (1) with a crystalline, self reinforcing rubber is very good, with high mechanical strength and adhesive(2) has a unique viscoelastic, high molecular weight, high Mooney viscosity, generally without mastication can use(3) non-polar, soluble in nonpolar solvents, good adhesion, good elasticity, hysteresis loss, bending deformation can flex repeatedly2, shortcomings: (1) non rubber ingredients, and large fluctuations (4% ~ 10%), so the quality is not uniform, containing unsaturated double bonds, easy agingApplication: tire, adhesive tape, rail, rubber roller, adhesive tape, general sealing ring, bridge support and inside and outside tire

- Q: The rubber strap is a little tight, is it better or a little loose?

- Generally speaking, men's wear watches do not overtighten but not too loose, it is best to wear after can be part of your wrist bone block does not decline (wrist bones are small and larger) bone behind tend to fine down where you can send some will say that gap does it mean to have a finger said after wearing in a small range on the floor but more close to the standard.

Send your message to us

Textile Carcass Conveyor Belt

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords