Rubber Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plastic packaging |

| Delivery Detail: | 30days |

Specifications

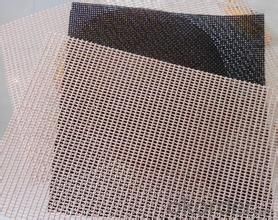

1. EP conveyor belt, steel cord belt, HR conveyor belt,chevron belt,etc

2. thickness: 3mm to 50mm .

3.width: 300mm to 2.2m

We can provide a huge gamut of superlative industrial conveyor belts that are used in varied applications with DIN22102.

Width : 400 mm to 2600 mm.

Length : Open or endless.

Plies : 2 to 7 Plies.

Cover Thickness : 0mm to 12 mm ,we could offer the conveyor belt have no top cover and upper cover.

Tensile Strength : 8 to 24 MPA.

Types of Synthetic Carcass : General Duty (GD), Extra Duty (ED) & Heavy Duty (HD).

Edges : Cut edges or molded.

Fabric : EP,NN,CC,TC.

Conveyor Belt Catalogue |

Rough top conveyor belt |

Steel cord conveyor belt |

Nylon Conveyor belt |

Polyester conveyor belt |

Polyester cotton conveyor belt |

Heat resistant conveyor belt |

High temperature resistant conveyor belt |

Common flame retardant conveyor belt |

Chemical resistant conveyor belt |

Oil Resistant conveyor belt |

Cold resistant conveyor belt |

Patterned conveyor belt |

Endless conveyor belt |

Foodstuff conveyor belt |

Whole-core flame retardant conveyor belt |

- Q: What is belt drive? What are the types and characteristics of belt drives?

- A: the belt drive is composed of a belt pulley (driven wheel) fixed on the driving shaft, a pulley (driven by a driven wheel) fixed on the driven shaft and a belt which is tightly sheathed on the wheelThe type of belt drive:The common driving types are flat belt drive, V belt drive, multi wedge belt drive and synchronous belt driveFlat belt transmission is the simplest structure in belt drive, which is suitable for the condition that the center distance is large, but it is not suitable for high speed transmission

- Q: Do I need to add grease to the V belt or belt?

- If you add lubricating oil, it is easy to slip or other accidents

- Q: Method for maintaining transmission belt

- Belt changeAfter the triangle belt fails, it should be replaced in time. If a triangle belt is used together, if one part or part of the utility model is practical, the other parts should be replaced at the same time, and the old and new belts can not be used together.4 、 belt cleaningThe triangle with butter, oil and grease easily after slipping and acceleration belt is damaged, should be timely cleaning with gasoline, can also be used as alkaline cleaning agent, not with oil.

- Q: How do I remove the air-conditioning compressor and the engine belt?

- Remove the refrigerant pipe under the belt and air conditioning compressor.

- Q: Hoist belt and pulley design?

- A type of belt, according to the need of power and small pulley speed, mostly choose B type V ordinary belt. Next to the V belt type selection according to the primary small round reference diameter, V belt, belt wheel speed datum diameter.After determining the belt type, the reference diameter is calculated according to the bonding relationship of the belt. When calculating, it is necessary to consider the factors such as the angle of the package, the length of the belt and the basic rated power of the single V belt.

- Q: What is the stress distribution in belt drive? Detailed

- Due to the tension of the initial tension sleeve on the two pulleys, the positive pressure on the contact surface of the belt and the pulley is under the action of the utility model. The tension on both sides of the belt is equal when not working.

- Q: Why should the belt adjust the tension?

- Belt tight will make the belt wear seriously, too loose, easy to slip phenomenon, so that the belt serious wear and tear, or even burned. In general, two rounds of distance about 1 meters, with the finger press the middle of the belt, should be vertical down 10-20 mm. The belt should be checked for the tension of the belt and adjusted at any time.

- Q: Some of the machines use belts and some use the transmission chain. They want to ask what conditions they use

- There are many kinds of belt drive: O belt, flat belt, trapezoid belt, wedge belt, synchronous belt, etc. each function is different, and the torque of B belt in trapezoid is great, so it is necessary to consider belt pulley angle and so on when designing

- Q: What are the factors determining the optimum tensioning force in belt drives?

- Because the belt is on the belt and the belt pulley to transmit motion and power, so in the assembly should be between the belt and pulley has a certain pressure, the belt tensioning and maintain adequate initial tension. By the use of a longer period of time, due to the long-term will be affected by tension, permanent deformation, elongation after transmission belt, reducing the friction between the belt and pulley, to enable transmission capacity is reduced, often slipping phenomenon, in order to maintain proper tension, reduce slippage, need to adjust the tensioning device.

- Q: Type of transmission belt? Pictures? And the characteristics of each kind of belt?

- 3. round belt. The circular belt is a circular belt with a round profile, which can be freely bent and driven. The belts are mostly made of polyurethane and usually have no core body, the structure is the most simple and the use is convenient. The circular belt has opened up a new way for belt transmission, and the amount of consumption in small machine tools, sewing machines, precision machines and other fields all over the world is increasing rapidly, and the potential is very great in the future. 4. gear belt. The toothed belt, also called synchronous belt, is divided into two types, one side toothed belt and two sided toothed belt. The former is mainly used in single shaft transmission, the latter is multi axle or reverse transmission. It is another new type of high efficiency transmission belt emerging from the world since 1980. The toothed belt is divided into two kinds of trapezoid and arc shapes according to the shape of the tooth, and the torque is the largest with the synchronous belt of the circular tooth. From the materials used, the toothed belt can be divided into rubber and polyurethane two major categories, while the former and ordinary rubber (usually chloroprene rubber) and special rubber (mostly saturated nitrile rubber) points. The structure is composed of steel cord or glass fiber and is made of rubber or nylon cloth. Hope to help you, hope to adopt!

Send your message to us

Rubber Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords