Aluminum Circle Plate for Non-Sticky Pot Pans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

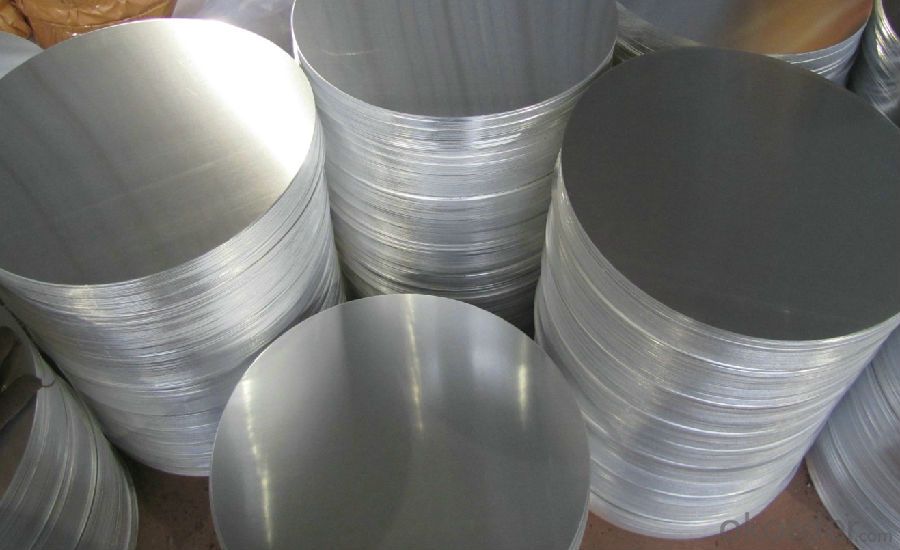

1.Structure of Aluminum Circle Plate for Pot Non-sticky Pans Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the Aluminum Circle Plate for Pot Non-sticky Pans

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

3.Aluminum Circle Plate for Pot Non-sticky Pans Images

4.Aluminum Circle Plate for Pot Non-sticky Pans Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Aluminum Circle Plate for Pot Non-sticky Pans

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Explain the environmental impact of using aluminum in construction materials.

- <p>Aluminum used in building materials has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, durable, and highly recyclable, which reduces waste and conserves resources. It also has good thermal conductivity, which can improve energy efficiency in buildings. However, the production of aluminum is energy-intensive and generates greenhouse gases, contributing to climate change. Additionally, the mining and processing of bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these issues, the recyclability of aluminum means that its environmental footprint can be significantly reduced through proper recycling practices.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative battery technologies?

- <p>Yes, aluminum can be used to make new types of batteries. Aluminum-air batteries, for instance, are a type of metal-air battery that uses aluminum as the anode and air as the cathode. These batteries have a high energy density and are lightweight, making them suitable for certain applications like electric vehicles and backup power systems. Research is ongoing to improve the efficiency and lifespan of aluminum-based batteries, addressing issues such as aluminum corrosion and the development of efficient air cathodes.</p>

- Q: Is aluminum a suitable material for use in solar panels?

- <p>Yes, aluminum is commonly used in solar panels, primarily for framing and mounting purposes. It is a lightweight, durable, and cost-effective material that provides structural support and protection against environmental elements. While the photovoltaic cells themselves are typically made from silicon, aluminum's role in the assembly is crucial for the overall performance and longevity of the solar panel system.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional recycling process?

- <p>Yes, aluminum can be recycled in different ways. Apart from the conventional recycling process, which involves melting and recasting, there are innovative methods being explored. One such method is mechanical recycling, where aluminum is cleaned, sorted, and processed into new products without melting. Another approach is chemical recycling, which breaks down aluminum into its constituent elements and then reassembles them into new materials. These alternative methods aim to reduce energy consumption and environmental impact while still effectively recycling aluminum.</p>

- Q: Is it possible to recycle aluminum at home?

- <p>Yes, aluminum can be recycled at home. It's easy to recycle as it's a lightweight, durable, and infinitely recyclable material. Simply clean and flatten aluminum cans, foil, and other aluminum products before placing them in your recycling bin. However, not all home recycling programs accept all types of aluminum, so check with your local recycling center for specific guidelines.</p>

- Q: What measures should be taken to ensure safety while working with aluminum?

- <p>When working with aluminum, it's important to follow safety precautions. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to prevent inhalation of aluminum dust. Ensure good ventilation to avoid the buildup of fumes. Use proper tools and equipment to handle aluminum, as it can become sharp and cause cuts. Be cautious of the heat generated during cutting or welding, as aluminum conducts heat quickly and can cause burns. Store aluminum in a dry place to prevent it from reacting with moisture, which can cause it to corrode. Lastly, be aware of the fire hazard associated with aluminum dust and take necessary fire prevention measures.</p>

- Q: What are some environmentally friendly options that can replace aluminum in various applications?

- <p>Sustainable alternatives to aluminum include biodegradable materials like bamboo and hemp, which can be used in construction and packaging. Stainless steel is a recyclable metal that can replace aluminum in many applications due to its durability and strength. Recycled aluminum itself is a sustainable option as it requires less energy to produce than new aluminum. Additionally, magnesium and titanium are lightweight metals that can be used in place of aluminum in certain industries. It's important to consider the specific application when choosing an alternative, as each material has its own set of properties and environmental impacts.</p>

- Q: Explain the economic and job market implications of using aluminum.

- <p>The use of aluminum has significant impacts on the economy and job market. It is a key material in various industries, including construction, automotive, aerospace, and consumer goods, which drives demand and economic growth. Aluminum production and processing create jobs directly in mining, refining, and manufacturing sectors, and indirectly in related services and supply chains. Additionally, its lightweight and corrosion-resistant properties make it valuable for energy-efficient transportation, contributing to environmental sustainability and opening new job opportunities in green technologies. However, it also presents challenges such as the need for energy-intensive production processes and the management of waste, which require innovative solutions and can lead to job creation in recycling and environmental management.</p>

- Q: Is aluminum a suitable material for manufacturing solar panels?

- <p>Yes, aluminum is commonly used in the manufacturing of solar panels. It is utilized primarily for the frame of the solar panel, providing structural support and protection. Aluminum is chosen for its lightweight, high strength, and corrosion resistance, which are ideal properties for outdoor applications like solar panels. It also helps in heat dissipation, which is beneficial for maintaining the panels' efficiency. While aluminum is not used in the actual photovoltaic cells, its role in the panel's construction is significant.</p>

- Q: Explain the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It's utilized in window frames, doors, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum's malleability allows it to be shaped into various forms, making it ideal for facades and decorative elements. It's also used in structural components like beams and columns, and in electrical wiring due to its excellent conductivity. Additionally, aluminum's sustainability makes it a preferred choice in green building practices, as it's recyclable and has a low environmental impact.</p>

Send your message to us

Aluminum Circle Plate for Non-Sticky Pot Pans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords