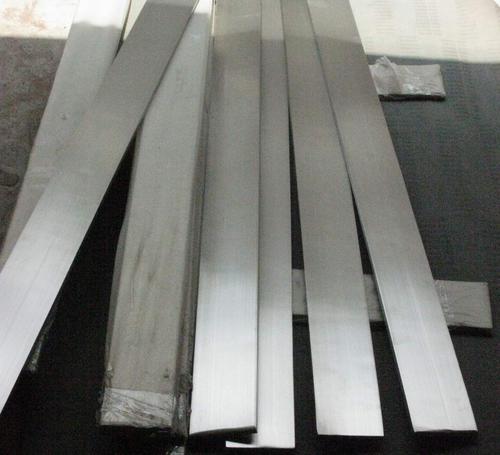

Frime Low Carbon Q195 Flat Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Frime Low Carbon Q195 Flat Bars at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Frime Low Carbon Q195 Flat Bars are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Frime Low Carbon Q195 Flat Bars are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: A36, SS400, Q235, Q195

Standard: ASTM, JIS, GB

Thickness:1.5mm-20mm

Width: 10mm-250mm

Packing: it is nude packed in bundles by steel wire rod

Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made inChina, shipping marks and other information request by the customer.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: Are steel flat bars resistant to fire or heat?

- Yes, steel flat bars are highly resistant to fire and heat due to their high melting point and thermal conductivity.

- Q: What is the difference between 60X6 and 50X4 flat steel in grounding?

- There are differences, mainly based on the local geological conditions, the purpose is to meet the requirements of grounding resistance.

- Q: Can steel flat bars be used for manufacturing architectural facades or cladding?

- Yes, steel flat bars can be used for manufacturing architectural facades or cladding. They offer strength, durability, and a sleek appearance, making them suitable for such applications. Additionally, steel flat bars can be easily fabricated and installed, making them a popular choice in architectural design.

- Q: How do steel flat bars perform in extreme weather conditions?

- Steel flat bars are known for their exceptional strength and durability, which makes them highly resistant to extreme weather conditions. They are capable of withstanding high temperatures, heavy rain, snow, and even strong winds. In extreme heat, steel flat bars have a high melting point, which means they can withstand prolonged exposure to intense heat without warping or losing their structural integrity. This makes them ideal for applications in areas with high temperatures, such as deserts or industrial settings. During heavy rain or snowfall, steel flat bars are highly resistant to corrosion and do not rust easily. This makes them suitable for outdoor applications where they may be exposed to moisture for extended periods. Moreover, their smooth surface allows water to run off easily, preventing the accumulation of water and reducing the risk of damage caused by freezing and thawing cycles. In areas prone to strong winds or storms, steel flat bars are known for their exceptional strength and stability. They can withstand high wind pressures and resist bending or breaking, making them a reliable choice for structures such as fences, barriers, and support beams. However, it is important to note that even though steel flat bars are highly resistant to extreme weather conditions, they still require proper maintenance to ensure their longevity. Regular cleaning, inspection, and applying protective coatings can help prevent any potential damage or deterioration caused by weathering. Overall, steel flat bars are a reliable choice for applications in extreme weather conditions due to their strength, durability, and resistance to corrosion.

- Q: Can steel flat bars be used for structural support?

- Yes, steel flat bars can be used for structural support. Steel flat bars are commonly used in construction and engineering projects to provide structural support, especially in applications where high strength and durability are required. They are often used as beams, braces, or supports in buildings, bridges, and other structures. Steel flat bars have excellent load-bearing capabilities and can withstand heavy loads and forces, making them suitable for structural support. Additionally, steel flat bars can be easily welded or bolted together to create larger structural elements, allowing for flexibility in design and construction.

- Q: What are the advantages of using steel flat bars over other materials?

- There are several advantages of using steel flat bars over other materials. Firstly, steel is known for its exceptional strength and durability, which makes it suitable for heavy-duty applications. It can withstand high levels of stress and is resistant to bending or warping. Secondly, steel flat bars offer excellent corrosion resistance, ensuring longevity and reducing maintenance costs. Additionally, steel is widely available and cost-effective compared to alternative materials like aluminum or titanium. Lastly, steel's versatility allows for various applications, including construction, manufacturing, and fabrication, making it a preferred choice for many industries.

- Q: Are steel flat bars available in different shapes, such as round or square?

- No, steel flat bars are typically available only in a flat shape. However, if you are looking for round or square steel bars, there are other types of steel bars that are specifically manufactured in those shapes. Round bars are cylindrical in shape, while square bars have straight, uniform sides, forming a square shape. These different shapes of steel bars cater to specific applications and are readily available in the market.

- Q: Can steel flat bars be used for making tools or toolboxes?

- Yes, steel flat bars can be used for making tools or toolboxes. Steel is a strong and durable material, making it suitable for constructing various tools and toolboxes that require strength and stability. Additionally, steel can be easily shaped and welded, allowing for the creation of customized tool designs.

- Q: What are the different cutting methods for steel flat bars?

- There are several cutting methods for steel flat bars, including sawing, shearing, and plasma cutting. Sawing involves using a saw blade to cut through the bar, while shearing uses a shearing machine to trim the material. Plasma cutting, on the other hand, involves using a high-temperature plasma torch to melt and separate the steel. Each method has its own advantages and is suitable for different applications and requirements.

- Q: What is the load-bearing capacity of a steel flat bar?

- The load-bearing capacity of a steel flat bar depends on various factors such as the dimensions of the bar, the type and grade of steel used, and the specific application or use case. Generally, steel flat bars are known for their high strength and load-bearing capabilities. To determine the load-bearing capacity of a steel flat bar, engineers consider several factors including the thickness, width, and length of the bar, as well as the type of load it will be subjected to (such as static or dynamic loads). Additionally, the type of steel used and its mechanical properties, such as yield strength and tensile strength, play a significant role in determining the load-bearing capacity. To provide a more specific answer, it would be necessary to know the exact dimensions and properties of the steel flat bar in question, as well as the intended use and load requirements. Consulting engineering specifications, structural analysis, or professional advice would be necessary to determine the precise load-bearing capacity for a particular steel flat bar in a specific application.

Send your message to us

Frime Low Carbon Q195 Flat Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords