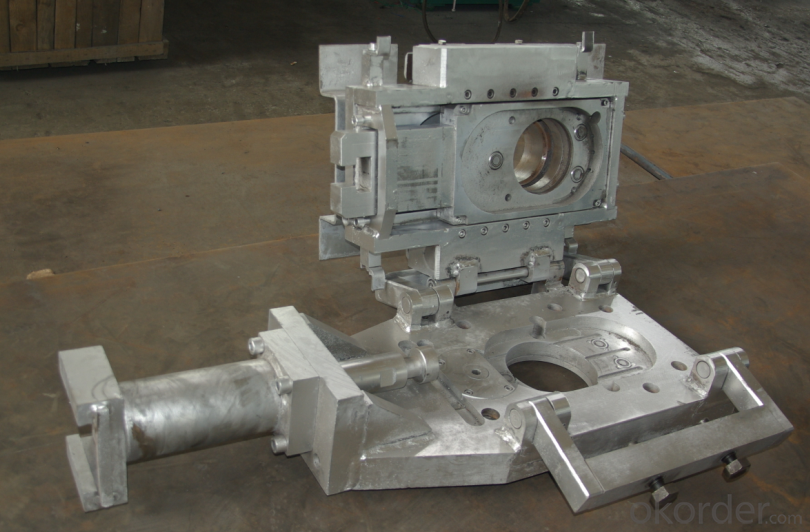

Monolithic Refractories Zirconia Slide Gate Nozzle Upper and Lower Nozzle Brick for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Shandong, China (Mainland) | Shape: | Plate | Material: | SiC,Zirconia,corundum |

SiO2 Content (%): | 0.2 | Al2O3 Content (%): | 0.3 | MgO Content (%): | less |

CaO Content (%): | less | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | less |

SiC Content (%): | 7% | Model Number: | B60,B50,C40 | Brand Name: | Shikai |

Density: | 3.0g/cm3 | Al2O3: | 85% | Compressive strength: | 100Mpa |

Apparent Porosity: | 10% | Refractoriness: | more than 1790℃ | Advantage: | high refractoriness, good thermal shock resistance, erosion resistance |

Usage: | steel plant ladle and tundish | Packing: | carton,pallets | C+SiC: | 5% |

product: | slide gate,upper nozzle,lower nozzle |

Packaging & Delivery

Packaging Details: | cartons,plastic film and pallets,wooden box,As requested. |

Delivery Detail: | within 30days after get your order |

Ladle nozzle brick,upper nozzle brick,lower nozzle brick

Product information:

1.Advantage:high refractoriness, good thermal shock resistance, erosion resistance and

scouring resistance, small hole diameter change, long service life, etc.

2.Product data:

Burnt Slide gate

Item B60,B50,C40type | Al-C Slide Gate | Al-Zr-C Slide Gate | ||||||

AlC-70 | AlC -75 | AlC -80 | AlC-85 | AlC -86 | AlZrC -70 | AlZrC-75 | AlZrC -77 | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 | 70 | 75 | 77 |

C+SiC,% | 7 | 7 | 5 | 5 | 4 | 7 | 7 | 7 |

ZrO2,% | - | - | - | - | - | 6 | 6 | 2.5 |

A.P.,% max | 10 | 10 | 10 | 10 | 7 | 10 | 10 | 10 |

B.D.,g/cm3 | 2.8 | 2.9 | 2.9 | 3.0 | 2.95 | 3.00 | 3.05 | 2.90 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 | 110 | 115 | 100 |

Unburned compound AlC Slide gate

Item B60,B50,C40type | Al-C Slide Gate | ||||

AlC-70A | AlC-75A | AlC-80A | AlC-85A | AlC-86A | |

Al2O3,% | 70 | 75 | 80 | 85 | 86 |

C,% | 7 | 7 | 5 | 5 | 4 |

A.P.,% max | 10 | 10 | 8 | 10 | 7 |

B.D. g/cm3 min | 2.8 | 2.9 | 3.0 | 3.0 | 2.95 |

C.C.S., MPa min | 65 | 70 | 100 | 100 | 100 |

zirconium core :

Item | ZN- 65 | ZN- 70 | ZN- 75 | ZN- 80 | ZN- 85 | ZN- 90 | ZN- 93A | ZN- 93B | ZN- 93C | ZN- 93D | ZN- 95A | ZN- 95B | ZN- 96 |

ZrO2(%) | ≥65 | ≥70 | ≥75 | ≥80 | ≥85 | ≥90 | ≥93 | ≥93 | ≥93 | ≥93 | ≥95 | ≥95 | ≥96 |

Bulk density (g/cm3) | ≥3.8 | ≥3.8 | ≥3.9 | ≥4.0 | ≥4.1 | ≥4.3 | ≥5.1 | ≥4.9 | ≥4.7 | ≥4.4 | ≥4.6 | ≥5.2 | ≥5.2 |

Apparent Porosity(%) | ≤23 | ≤22 | ≤22 | ≤20 | ≤20 | ≤20 | ≤13 | ≤15 | ≤18 | ≤20 | ≤20 | ≤9 | ≤5.6 |

Thermal shock resistance (cycles)(1100℃,water cooling) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >8 | >10 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the common failure mechanisms of monolithic refractories in the iron and steel industry?

- Common failure mechanisms observed in monolithic refractories within the iron and steel industry include: 1. Thermal spalling: Monolithic refractories endure extreme temperature variations during the iron and steel production process. These rapid changes in temperature can cause the refractory material to expand and contract, resulting in thermal stress and eventual spalling. This failure mechanism is particularly prevalent in areas where the refractory is exposed to elevated temperatures, such as the hot face of a furnace. 2. Chemical attack: The iron and steel production process involves the utilization of various chemicals and molten metal, which can react with the refractory material over time. Chemical attack can lead to the deterioration of the refractory, resulting in cracks, erosion, and eventual failure. Slag, alkalis, sulfur, and other impurities present in the production environment are commonly responsible for this type of damage. 3. Abrasion: The movement of materials, such as iron ore, coke, and fluxes, can cause abrasion on the refractory lining. This mechanical wear and tear weaken the refractory material, eventually leading to failure. Areas experiencing high material flow rates or turbulence, such as tapholes or launder systems, are particularly prone to abrasion. 4. Corrosion: Monolithic refractories can be susceptible to corrosion caused by gases, liquids, and solids found in the iron and steel production environment. Corrosion occurs due to the presence of oxygen, water vapor, and various chemical compounds, such as carbon monoxide and sulfur compounds. It results in the formation of corrosive products, such as oxides or sulfides, which degrade the refractory material over time. 5. Mechanical stress: Monolithic refractories may undergo mechanical stress due to factors like thermal expansion and contraction, vibration, or mechanical impact. Excessive mechanical stress can lead to the development of cracks or fractures in the refractory lining, compromising its integrity and resulting in failure. To mitigate these failure mechanisms, it is crucial to select appropriate refractory materials, conduct regular inspections, and perform necessary maintenance. Furthermore, designing refractory linings that consider specific operational conditions and employing appropriate installation techniques can enhance their performance and lifespan within the iron and steel industry.

- Q: How do monolithic refractories perform in rotary hearth furnace applications?

- Monolithic refractories perform exceptionally well in rotary hearth furnace applications due to their ability to withstand high temperatures, thermal shock, and mechanical stresses. Their unique properties and composition make them highly resistant to chemical attacks and erosion, ensuring long-lasting and reliable performance in these demanding environments. Additionally, their easy installation and repair process make them a preferred choice for rotary hearth furnace applications.

- Q: How are monolithic refractories installed and repaired in iron and steel plants?

- Monolithic refractories play a vital role in iron and steel plants, offering resistance to high temperatures and insulation. They are widely utilized in various applications, including lining furnaces, ladles, and equipment that comes into contact with molten metal. The process of installing monolithic refractories in iron and steel plants typically involves several sequential steps. Initially, the surface where the refractory material will be applied must be prepared, removing any existing refractories or contaminants. This can be accomplished through mechanical means, such as sandblasting, or through chemical cleaning processes. Following this, the monolithic refractory material is mixed with water or a suitable binder to achieve a workable consistency. The resulting mixture is then applied to the prepared surface using a variety of techniques, such as gunning, casting, or troweling. Gunning involves using a high-pressure gun to spray the refractory material onto the surface, while casting involves pouring the mixture into a mold. Troweling is a manual method that entails spreading the refractory material with a trowel. After the application of the refractory material, it must be appropriately cured or dried. This is usually accomplished by allowing the material to air dry or by employing controlled heating. The curing process is imperative to ensure that the refractory material develops the desired properties, including strength and resistance to thermal shock. Regarding repairs, monolithic refractories in iron and steel plants may deteriorate over time due to the harsh operating conditions. When repairs are necessary, damaged or worn-out sections of the refractory lining need to be identified. This can be achieved through visual inspection or non-destructive testing techniques. The repair procedure generally involves removing the damaged refractory material by chipping, drilling, or cutting. The surface is then prepared as previously mentioned, and a fresh batch of monolithic refractory material is applied to reinstate the lining. The repair material must be compatible with the existing lining and provide similar properties to ensure the overall integrity of the refractory structure. It is important to highlight that the installation and repair of monolithic refractories in iron and steel plants necessitate skilled personnel who possess knowledge of refractory materials and installation techniques. Additionally, proper safety precautions should be adhered to in order to safeguard workers from potential hazards, such as exposure to high temperatures, dust, and chemicals. Regular inspection and maintenance are also critical to identify any potential issues early on and prevent major failures that could affect production and safety.

- Q: How do monolithic refractories perform in rotary kiln applications?

- Monolithic refractories perform exceptionally well in rotary kiln applications due to their high thermal shock resistance, excellent chemical resistance, and superior strength at high temperatures. Their ability to withstand extreme heat and harsh chemical environments makes them ideal for lining the interior of rotary kilns. Additionally, monolithic refractories offer easy installation and maintenance, ensuring efficient and reliable kiln operations.

- Q: What are the advantages of using plastic refractories in the iron and steel industry?

- Plastic refractories provide numerous benefits in the iron and steel industry. Firstly, their thermal insulation properties are exceptional. They possess a low thermal conductivity, enabling them to effectively retain heat and prevent excessive heat loss during manufacturing. This is critical for the proper functioning of furnaces and equipment, as maintaining high temperatures is essential. Secondly, plastic refractories exhibit superior resistance to chemical attack and corrosion. They can endure exposure to various chemicals, including molten metals and slag, without deteriorating or losing their structure. This is particularly important in an industry where materials frequently encounter highly corrosive substances. Moreover, plastic refractories offer the advantage of easy installation and repair. Unlike other refractory materials, they can be easily shaped and molded into the desired form. This allows for precise fitting and swift installation. Additionally, if damaged or worn, they can be easily repaired or patched, reducing downtime and maintenance costs. Additionally, plastic refractories possess excellent mechanical strength and abrasion resistance. This enables them to endure the physical stresses and mechanical forces present in the iron and steel industry, such as vibrations, impacts, and mechanical loading. Their high resistance to wear and tear ensures longevity and reduces the need for frequent replacements. Lastly, plastic refractories have a high resistance to thermal shock. They can withstand rapid temperature changes without cracking or spalling. This is advantageous in an industry where materials are subjected to extreme temperature differentials, such as during the heating and cooling cycles of furnaces. In conclusion, the utilization of plastic refractories in the iron and steel industry provides numerous advantages including excellent thermal insulation, resistance to chemical attack, ease of installation and repair, good mechanical strength, abrasion resistance, and high thermal shock resistance. These properties make plastic refractories an ideal choice for various applications, ensuring efficient and reliable operations.

- Q: How do monolithic refractories withstand high temperatures and thermal shocks?

- Due to their unique composition and design, monolithic refractories possess the ability to endure high temperatures and thermal shocks. These refractories, referred to as "monolithic" due to their single-piece or structured form, can withstand extreme heat and sudden temperature changes commonly experienced in high-temperature applications. The utilization of high-quality raw materials is a key factor enabling monolithic refractories to withstand high temperatures. These materials are meticulously chosen for their heat and thermal stress resistance. Common components include silica, alumina, magnesia, and other refractory minerals with high melting points. Furthermore, the manufacturing process plays a vital role in enhancing the thermal resistance of monolithic refractories. The raw materials are blended with binders, such as clay or cement, to create a homogeneous mixture. This mixture is then shaped and installed in its final position, either through pouring or gunning, depending on the application. The binder ensures that the refractory maintains its shape and integrity during thermal cycling. In addition, monolithic refractories exhibit excellent thermal conductivity and low thermal expansion properties. This enables efficient heat transfer and dissipation, minimizing the risk of thermal stress and cracking. The low thermal expansion also reduces the likelihood of spalling or delamination, which is crucial for withstanding thermal shocks. Another contributing factor to the high-temperature resistance of monolithic refractories is their ability to form a protective layer or slag on the surface. This layer acts as a barrier, preventing direct contact between the refractory and corrosive materials or aggressive atmospheres. It significantly improves the refractory's longevity and resistance to thermal shocks. Overall, the combination of high-quality raw materials, meticulous manufacturing techniques, and advantageous thermal properties allows monolithic refractories to endure high temperatures and thermal shocks. These refractories find extensive use in various industries, including steel, cement, glass, and petrochemical, as reliable linings in furnaces, kilns, and other high-temperature equipment.

- Q: How are monolithic refractories different from traditional refractory bricks?

- Monolithic refractories refer to a type of refractory material that is composed of a single, homogeneous structure, as opposed to traditional refractory bricks which are made by binding individual bricks together. This fundamental difference in structure leads to several distinctions between monolithic refractories and traditional refractory bricks. Firstly, monolithic refractories offer greater flexibility and versatility in terms of shape and installation. Since they are not bound by individual bricks, monolithic refractories can be easily molded and shaped to fit specific applications and complex geometries. This makes them ideal for lining various types of furnaces, kilns, and other high-temperature equipment. Secondly, monolithic refractories typically have superior thermal shock resistance compared to traditional refractory bricks. Their uniform structure allows for better distribution of heat, minimizing the risk of thermal stress and cracking. This characteristic makes monolithic refractories particularly suitable for applications with rapid temperature fluctuations or severe thermal cycling. Additionally, monolithic refractories often exhibit better overall performance in terms of strength, mechanical properties, and resistance to chemical attack. The absence of joints and seams in monolithic refractories eliminates potential weak points, resulting in a more durable and reliable lining. Moreover, the homogeneous structure of monolithic refractories provides better resistance to corrosive agents, ensuring prolonged service life in harsh environments. Lastly, monolithic refractories offer advantages in terms of installation and maintenance. Their monolithic nature simplifies the installation process, reducing labor and time requirements. Additionally, repairs and maintenance of monolithic refractories can be carried out more easily and cost-effectively compared to traditional refractory bricks, which may require the replacement of entire sections or bricks. In summary, monolithic refractories differ from traditional refractory bricks in their structure, flexibility, thermal shock resistance, performance, and installation characteristics. These differences make monolithic refractories a preferred choice in many high-temperature applications, offering improved efficiency, durability, and ease of use.

- Q: How do monolithic refractories contribute to the reduction of emissions in iron and steel plants?

- Monolithic refractories play a crucial role in reducing emissions in iron and steel plants by providing various benefits and solutions to the environmental challenges faced by these industries. Firstly, monolithic refractories are used to line the high-temperature zones of furnaces, such as blast furnaces and electric arc furnaces, that are integral to the iron and steel production processes. These refractories have excellent thermal insulation properties, which help to minimize heat loss and improve energy efficiency. By reducing heat loss, less fuel is required to maintain the desired temperature, resulting in lower energy consumption and subsequently lower emissions. Furthermore, monolithic refractories also contribute to emissions reduction by enhancing the combustion process. They are designed to resist thermal shock and withstand extreme temperatures, ensuring that the furnaces operate at optimal conditions. This, in turn, leads to more efficient combustion of fuels and raw materials, reducing the release of harmful gases and pollutants into the atmosphere. In addition to their thermal properties, monolithic refractories also possess excellent resistance to chemical attacks and corrosion. This is particularly important in iron and steel plants, where aggressive substances such as molten metal, slag, and gases are present. By providing a protective lining, these refractories prevent the degradation of furnace walls and other equipment, reducing the risk of leaks and emissions. Moreover, monolithic refractories are often used in the construction of pollution control devices, such as flue gas desulfurization systems and baghouses. These systems are designed to capture and remove pollutants from the flue gases generated during iron and steel production. The use of refractories in these applications ensures the durability and longevity of these systems, allowing them to operate efficiently and effectively in reducing emissions. Overall, monolithic refractories contribute significantly to emissions reduction in iron and steel plants through improved energy efficiency, enhanced combustion, corrosion resistance, and support for pollution control systems. By implementing these refractories, the industry can minimize its environmental footprint and move towards more sustainable and responsible production processes.

- Q: How do monolithic refractories prevent thermal shock in the iron and steel industry?

- The iron and steel industry heavily relies on monolithic refractories to prevent thermal shock. These refractories offer exceptional thermal insulation and resistance to extreme temperatures, playing a vital role in maintaining the integrity of the refractory lining. Thermal shock occurs when there is a sudden and significant change in temperature, leading to stress and cracks in the refractory lining. Given the extremely high temperatures that can be reached in the iron and steel industry, the risk of thermal shock is particularly pronounced. To combat this, monolithic refractories possess a low thermal conductivity, enabling them to effectively insulate against rapid temperature fluctuations. This insulation property allows them to endure the extreme temperatures involved in the iron and steel production process without compromising their structural integrity. Moreover, monolithic refractories are specifically engineered to exhibit high thermal shock resistance. This means they can effectively absorb and distribute the thermal stresses caused by temperature variations, thereby minimizing the likelihood of cracking or spalling. Aside from their exceptional thermal insulation and shock resistance, monolithic refractories also demonstrate outstanding corrosion and erosion resistance. This is especially important in the corrosive environment of the iron and steel industry, where molten metals, slag, and gases are present. By providing a dependable and long-lasting lining in furnaces, ladles, and other equipment utilized in the iron and steel industry, monolithic refractories ensure that thermal shock is mitigated. Consequently, this helps to maintain the efficiency and productivity of the production process while extending the lifespan of the equipment.

- Q: What are the recommended curing times for monolithic refractories?

- The recommended curing times for monolithic refractories can vary depending on the specific type of refractory and its application. However, in general, it is important to follow the manufacturer's guidelines for curing times to ensure the proper setting and development of the refractory material. For conventional castable refractories, a typical curing time can range from 24 to 48 hours. During this period, it is essential to control the temperature and humidity conditions to allow for the hydration and hardening of the castable. This curing time is crucial to achieve the desired strength and durability of the refractory lining. On the other hand, low cement or ultra-low cement castables may require a longer curing time due to their reduced water content. These refractories often need a curing period of 48 to 72 hours to allow for proper bonding and solidification. For gunning mixes or shotcrete applications, the curing time might be shorter, usually around 8 to 12 hours. This faster curing process is facilitated by the addition of accelerators to the mix, which promote rapid setting and hardening. It is important to note that these recommended curing times are just general guidelines, and specific recommendations may vary depending on factors such as ambient temperature, humidity, and the specific refractory material being used. Therefore, it is always advisable to consult the manufacturer's instructions or seek guidance from a refractory specialist to ensure optimal curing and performance of the monolithic refractory.

Send your message to us

Monolithic Refractories Zirconia Slide Gate Nozzle Upper and Lower Nozzle Brick for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords