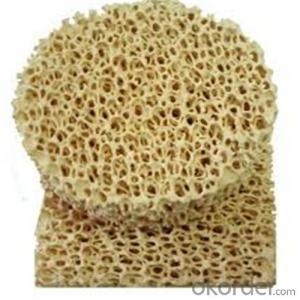

Ceramic Filter Plate for Zirconia Ceramic Foam Filter in Iron Foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Alumina Ceramic Foam Filter for Iron Foundry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | carton and pallet, or as customers' requirement |

| Delivery Detail: | 30 days after receiving the downpayment |

Specifications

Alumina ceramic foam filter

1.even aperture, high porosity, proper sinter

2.high strength of anti-flexing and anti-compression

Alumina ceramic foam filter

The product, adopted good portiforium foam and high purity ceramic , effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant.

Application:

For the filtration of molten steel and alloy,large scale iron casting

Product standard:China national GB/T 25139-2010

Zirconia ceramic foam filters are determined for filtering of steel and steel alloys up to the temperature of 1700 °C.

Filters are recommended especially for high quality grades of alloys.

-Drop turbulent of molten steel and alloy

-Improve accepted rate of steel casting

-Reduce foreign matter of steel casting

-Drop twice oxide flaw

-Reduce second-face flaw after machine process

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic foam filters are different from aperture specifications from 10 to 45ppi, with different sizes and shapes.

Besides the general specification ,we can offer the product according to the customers requirements.

Form A Ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2

| Pressure resistence intensity in normal temperature N/cm2

| Pressure resistence intensity in high temperature N/cm2

| Refractory temperature

| Air discharging capability cm3/g

| Porosity %

|

15-100 | 10-45 | 0.35-0.45 | ≥38 | ≥80 | ≥45 | ≥1800 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of ceramic foam filter

Specification mm | Area M2

| Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

178X178X50 | 0.0213 | 57.00 | 25-45 | 4.2 |

229X229X50 | 0.0387 | 118.00 | 35-102 | 6.9 |

305X305X50 | 0.0745 | 198.00 | 90-165 | 13.8 |

381X381X50 | 0.122 | 325.80 | 130-265 | 23.2 |

432X432X50 | 0.160 | 427.20 | 210-350 | 34.5 |

508X508X50 | 0.227 | 606.60 | 280-465 | 43.7 |

585X585X50 | 0.341 | 772.20 | 370-540 | 57.3 |

Other products:

For Us:

Welcome to visit our factory~

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- At this time, take the filtrate (this is not the first water slurry) will pollute the ceramic filter pipe, friction ring, filtrate pump, may damage the vacuum system, remaining in the pipeline in the pulp will recoil pressure under the action of pollution caused by the other ceramic plates, ceramic plates blocked him. Once the ceramic plate is broken (depending on the severity), it will make the vacuum distortion, resulting in ceramic filter suction effect worse or even no suction!

- Q: Why should filter core be used in backwash of ceramic filter?

- The filter in the water filter of ceramic filter is used for filtering water.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The incoming mud content, fine particle size, pulp itself is not suitable for the use of ceramic filter dehydration, if the use of ceramic filter dehydration in this case, will accelerate the blockage of ceramic filter plate, blocking the situation after the second reference description.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q: Why does not the iron filter of the ceramic filter work?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- Users such as pulp size is too small, too much mud, after analysis, the following methods of testing, the results have improved, it may wish to try the following methods, perhaps of help:The vacuum degree is about -0.08MPa.Adjust spindle speed and increase drying time.Ceramic filter plate with suitable pore size range.Ceramic filter plate brand on the market range, its quality is good or bad, the feed condition itself is not an ideal situation, such as ceramic filter plate with the aperture to the mine conditions do not match, it will exacerbate the effects of poor, life is short.It can shorten the combined cleaning cycle, strengthen the cleaning effect and prolong the cleaning time.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Replace ceramic filter plate:Different users because of pulp particle size and different characteristics, the service life is long and short of ceramic filtering plate. For the use of a long time and after the method 1 and 2, the effect of slurry suction is still very poor, we should consider replacing the new ceramic filter board.

- Q: What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

- Q: What are the functions of honeycomb ceramic filters?

- High quality and high density straight hole mesh, the product has high heat resistance and impact resistance properties of cast high fever temperature, design straight hole to guarantee the balance between strength and flow, effectively remove impurities and slag particles, the mechanical properties of casting, the surface quality and the qualified rate of products is greatly improved.

Send your message to us

Ceramic Filter Plate for Zirconia Ceramic Foam Filter in Iron Foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords