Zirconia Ceramic Ball Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 1/2" zirconia ball PACKING: Industrial packing |

| Delivery Detail: | 10~35 DAYS |

Specifications

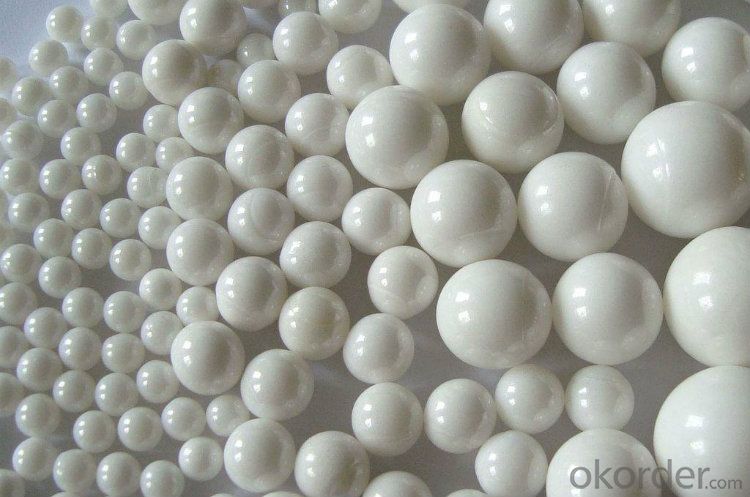

1/2" zirconia ball

High percision ceramic ball

1/2" zirconia ball

Ceramic ball ZRO2 1/2"

1.Ceramic ball D 1/2"

2.Ceramic ball, ZRO2 white color

3.Precision G5, G10

4.Brand KOMASU,neutral

1/2" zirconia ball

Specifications of Ceramic ball :

1) ceramic ball type: ZRO2 1/2"

2)Material: ZRO2 white color

3) D 1/2"

4) Precision G5, G10, G20

5) Tolerance: ABEC-1 (P0), ABEC-3 (P6),ABEC-5(P5)

6) Packing: industrial packing or individual box packing, carton, pallet

7) Brand: KOMASU, OEM

Features of 1/2" zirconia ball Ceramic ball : -ZRO2, SI3N4, SIC

1.59% lighter than steel ball, which means less centrifugal force and less wear on the groove during high speed and acceleration.

2.44% larger elastic modulus, which means less deformation under load.

3. Harder with Rockwell hardness as 78.

4. Smaller friction coefficient.

5. Only 1/4 coefficient of thermal expansion of steel, can endure sharp fluctuation of temperature.

6. Superior surface finish can be achieved.

7. Can endure high temperature with high hardness and strength up to 1050C.

8. Never rust, and can roll without lubrication.

9. More corrosion resistant than steel.

10. Free of metal contamination.

11. Non-magnetic.

12. Electric isolation.

Application of Ceramic 1/2" zirconia ball Ball:

Ceramic ball is generally assembled in bearing for application in high-tech industry such as aerospace, national defense, chemical industry, metallurgical, medical, food, oil plant, electronic etc.

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- Users such as pulp size is too small, too much mud, after analysis, the following methods of testing, the results have improved, it may wish to try the following methods, perhaps of help:The vacuum degree is about -0.08MPa.Adjust spindle speed and increase drying time.Ceramic filter plate with suitable pore size range.Ceramic filter plate brand on the market range, its quality is good or bad, the feed condition itself is not an ideal situation, such as ceramic filter plate with the aperture to the mine conditions do not match, it will exacerbate the effects of poor, life is short.It can shorten the combined cleaning cycle, strengthen the cleaning effect and prolong the cleaning time.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: Does the ceramic factory use hydrochloric acid?

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the ceramic filter works, the operation may be as follows: 1. The feed is injected and the pulp is injected into the tank of the ceramic filter. 2, mixing system, ceramic filter stirring rake back and forth mixing, driven by mixing reducer. 3, spindle rotation, material level reached a certain range, through the spindle speed machine to drive the ceramic filter disk rotation.

- Q: Can the ceramic plate filter the hot air?

- The vacuum degree of the ceramic filter in the vacuum system is about -0.085MPa. If the abnormal vacuum is found, the normal vacuum suction will not be available, and the suction effect will be poor, even without suction. If the vacuum is abnormal, should adhere to the vacuum pump, vacuum connection pipe is whether the fault Water Leakage leakage, distribution valve friction sealing, ceramic filter plate is connected with the rubber tube is aging or exfoliation, ceramic filter plate rupture.

Send your message to us

Zirconia Ceramic Ball Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches