High-Quality Ceramic Filter Plate - Silicon/Alumina Carbide Ceramic Foam Filter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 1000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

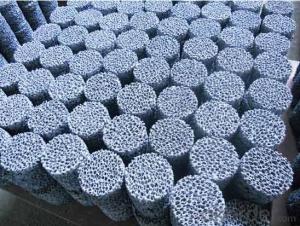

Quick Details for Alumina/ Silicon Carbide Ceramic Foam Filter for Foundry Industry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: |

Packaging & Delivery

| Packaging Details: | standard seaworthy/airworthy export packing/as your request |

| Delivery Detail: | 7-15days |

Specifications

Silicon Carbide Ceramic Foam Filter work at more than 1500 Degree Celsius, filter moten iron and copper in related casting.

Silicon Carbide Ceramic Foam Filter

Ceramic Foam Filter is the third generation filter, compared with traditional filtering materials(ceramic honeycomb filter, extruded filter), our Ceramic Foam Filter have the advantages as below:

1. High thermal stability, stable chemical composition in high temperature,avoid the chemical reaction with the filtered molten metal.

2. High mechanical strength, large specific surface,efficient in purifying the metal flow.

3. Lower the filtering head loss,easy-operating,save energy. Smooth the metal flow,avoid the spray, spatter and backset,improve the exterior quality of the casting product,prevent the pore disfigurement,reduce the inferior rate.

4. Various size, shape and aperture,suitable for kinds of casting technique.

The Ceramic Foam Filter are widely used in non-ferrous metal smelt, Foundry Industrial of Copper, Aluminum Alloy, Cast Iron, Cast Steel and high temperature fume separator, special filling. silicon carbide ceramic foam filter been used to filter molten iron and copper liquid in the iron casting industry, improve the casting product quality highly.

Physical and chemical properties

Material | Alumina | Silicon Carbide | Zirconia | Magnesia |

Color | White | Grey black | Yellow | Dark yellow |

Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | 8-60ppi |

Porosity | 80-90% | 80-90% | 80-90% | 80-90% |

Refractoriness | ≤1100°C | ≤1500°C | ≤1700°C | ≤1000°C |

Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | >0.6Mpa |

Compression Strength | >0.8Mpa | >0.9Mpa | >1.2Mpa | >0.8Mpa |

Volume-weight | 0.3-0.45g/cm3 | 0.35-0.5 g/cm3 | 0.9-1.5 g/cm3 | 0.35-0.5 g/cm3 |

Thermal shock resistance | 6times/1100°C | 6times/1100°C | 6times/1100°C | 6times/1100°C |

Application | Aluminium , Aluminium alloys and other Non-ferrous alloys | Ductile Cast Iron, Malleable Cast Iron,Gray iron and other Cast Iron | High melting point metal alloys likeSteel,AlloySteel,Stainless Steel etc | Magnesium and High-Active Alloy |

Specifications for Alumina Casting

Dimensions (mm) | Dimensions (inch) | Pouring Rate (kg/s) | Filtration Capacity (ton) |

178×178×50 | 7×7×2 | 0.2-0.6 | 5 |

228×228×50 | 9×9×2 | 0.3-1.0 | 10 |

305×305×50 | 12×12×2 | 0.8-2.5 | 15 |

381×381×50 | 15×15×2 | 2.2-4.5 | 25 |

430×430×50 | 17×17×2 | 3.0-5.5 | 35 |

508×508×50 | 20×20×2 | 4.0-6.5 | 45 |

585×585×50 | 23×23×2 | 5.0-8.6 | 60 |

Specification for Iron casting

Dimension (mm) | Pouring Rate (kg/s) | Filtration Capacity (kg) | ||

Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

40×40×22 | 4 | 3 | 65 | 32 |

50×50×22 | 6 | 4 | 100 | 52 |

75×50×22 | 9 | 6 | 150 | 75 |

75×75×22 | 14 | 9 | 220 | 100 |

100×50×22 | 12 | 8 | 200 | 100 |

100×75×22 | 18 | 12 | 300 | 150 |

100×100×22 | 25 | 16 | 400 | 200 |

150×150×22 | 50 | 36 | 900 | 450 |

Size & Color is as your request.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- The filter plate of ceramic filter is afraid of frost and should be protected.

- Q: Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- Ceramic filter is mainly composed of system, roller system, mixing discharge system, vacuum system, liquid discharge system, scraper system, washing system, cleaning system, automatic control system, and these parts body frame.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like device, through the pump) scraper discharge, discharge will complete a ceramic filter in the absorption cycle, slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles will cause blockage of filter media lose permeability so that the filtering effect of variation, in order to reduce the possibility of blockage, ceramic filter will enter the backwash (this process is like a water jet device). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

- Q: Why should filter core be used in backwash of ceramic filter?

- The filter in the water filter of ceramic filter is used for filtering water.

- Q: What are the materials that make up the ceramic mold?

- Ceramic membrane, also known as CT film, is one of the solid membrane, the earliest by Japan's large Japanese printing company and Toyo ink company in 1996, the introduction of the market. The ceramic coating is mainly A12O3, Zr02, Ti02 and Si02 of inorganic materials such as porous membrane preparation, the pore size of 250mm. Has good chemical stability, acid resistance, alkali resistance, solvent resistance, high mechanical strength, can reverse flushing: anti microbial ability: high temperature, narrow pore size distribution, higher separation efficiency characteristics, has been widely used in food industry, biological engineering, environmental engineering, chemical industry, petroleum chemical industry, metallurgy industry etc. The market sales, with an annual growth rate of 35% growth. Compared with plastic products of ceramic membrane with similar high cost, but also has many advantages, it is hard to withstand strong, durable, not easy to have chemical resistance village, invasive and high temperature liquid cleaning liquid has a stronger ability to resist, its main drawback is the price expensive. _ complex manufacturing process

- Q: Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: What's the acid of the ceramic filter plate?

- Ceramic filter boards tend to clog and acid washing is used to dissolve and dredge blockages in their pores.

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q: What is the backwashing pressure of the ceramic filter?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like syringe pumping), and then through the scraper discharge, after unloading, ceramic filter machine is complete a cycle in the absorption slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles blockage will make the filter medium permeability and filtering effect of the loss from the poor, in order to reduce the possibility of blockage ceramic filter, will enter the backwash (this process is like a water jet injector). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

Send your message to us

High-Quality Ceramic Filter Plate - Silicon/Alumina Carbide Ceramic Foam Filter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 1000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords