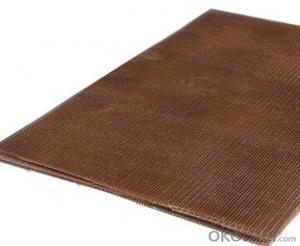

High Silica Fiberglass Mesh Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high silica mesh casting filter can effectively remove slag,refractory particles and non-metallic inclusions from molten metals.It is developed as a low cost but with rather filtration efficiency alternative to ceramic filters.

Made from specially treated silica yarns,silica mesh filters are capable of withstanding pouring temperatures up to 1620 Degree C.

Silica mesh filters are ideal for in-mold filtration of gray, malleable,white,compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

ADVANTAGES:

• Low cost and easy to use

• Improves fluidity and metal distribution

• Removes micron sized inclusions and impurities

• Can be used with existing pattern equipment

• Eliminates inclusions created by ceramic chips

APPLICATIONS:

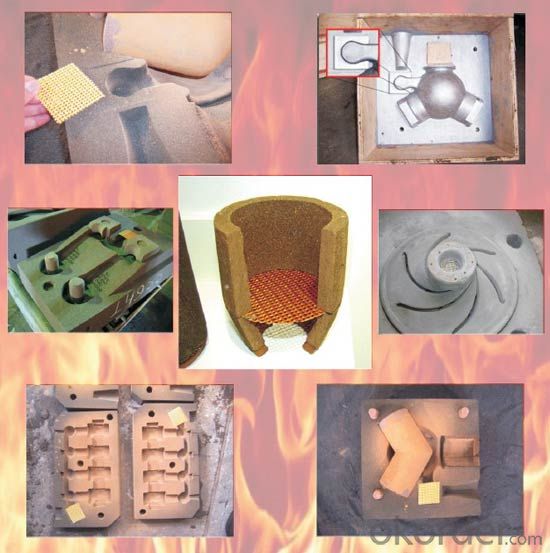

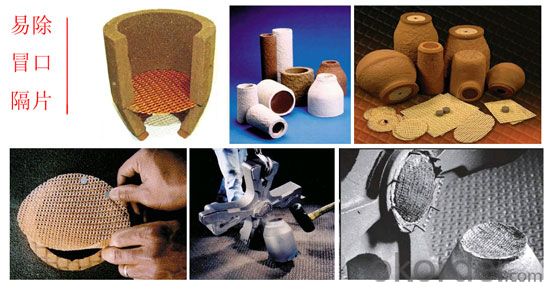

• Cut pieces for in mold filtration like sand casting,gravity casting,etc.

• Cut pieces for riser sleeves,bottom or across ports in walls

• Cut pieces to provide a weakened plane for riser knock-off

• Cup shapes for investment casting

SPECIFICATION:

Model No. | SiO2% | Thickness | Mesh size | Max.Temp. | Open area | Max.work time |

HSFG-15 | ≥96 | 0.35mm | 1.5x1.5mm | 1450℃ | 55% | 10minutes |

HSFG-20 | ≥96 | 0.35mm | 2.0x2.0mm | 1450℃ | 60% | 10minutes |

HSFG-25 | ≥96 | 0.35mm | 2.5x2.5mm | 1450℃ | 70% | 10minutes |

HSFG-S15 | ≥96 | 0.98mm | 1.5x1.5mm | 1620℃ | 22% | 15seconds |

HSFG-S20 | ≥96 | 0.98mm | 2.0x2.0mm | 1620℃ | 26% | 15seconds |

HSFG-S25 | ≥96 | 0.98mm | 2.5x2.5mm | 1620℃ | 32% | 15seconds |

FILTERING TIPS:

• Copper alloys&leaded bronze:1.5x1.5mm mesh

• Gray Iron:1.5x1.5mm mesh

• Ductile Iron:2.0x2.0mm &2.5x2.5mm mesh

• Small scale steel:1.5x1.5mm mesh

*Cut pieces can be rectangular or round,size from 20mm to 900mm.

*Preformed cup filter OD can be 100/110/115/120mm or as per request.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- In addition, the temperature is one of the factors affecting the filter suction effect of ceramic filter. The lower the temperature, the worse the suction effect.Therefore, the ceramic filter plate, especially the ceramic filter plate after use, should be protected under low temperature environment.

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: What are the materials that make up the ceramic mold?

- At present, the commercialized porous ceramic membranes are mainly composed of 3 types: flat plate, tubular and multi channel. Flat film is mainly used for small-scale industrial production and laboratory research. The tubular membrane is combined with rice to form a heat exchanger similar to a column tube heat exchanger, which can increase the loading capacity of the membrane, but is gradually withdrawn from industrial application due to its strength problem. The size of the applied ceramic membrane usually adopts a multi channel configuration, that is, a plurality of channels are distributed on a circular cross-section, and the number of general channels is 7, 19 and 37. The main business of the inorganic ceramic membrane preparation technology: using solid particle sintering preparation carrier and microfiltration membrane by sol-gel method in the preparation of ultrafiltration membrane: glass membrane by phase separation method: using special technology (such as chemical vapor deposition, electroless plating, etc.) the preparation of microporous membrane or dense membrane. Its basic theory involves colloid and surface chemistry, material chemistry, solid state ion science, material processing and so on.

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- The backwashing system of ceramic filter is usually made up of water inlet, water inlet, pressure gauge, water filter and filtered water pressure gauge, and then connected to the inside of ceramic filter. Such as the discovery of ceramic filter recoil pressure became smaller or even no recoil pressure, you can carefully observe the surface of the ceramic filter plate is wet or ceramic filter plate wear without water injection at the discharge point, investigation and the reasons for the following aspects:Is the water inlet pressure or normal?How about the sealing performance of the water filter? Does the filter element need to be replaced?Is the recoil system piping (metal pipe, ceramic filter plate, connecting pipe, etc.) broken, leaking or dripping?Is the distributor valve properly installed and is it worn?Are there any cracks in the ceramic filter plate?Is the pressure gauge broken?The most likely reason is 1, 2, two, the best water should not be too dirty, filter should be replaced regularly. I hope the answer can help you.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- Whether the ore conditions are changed, such as pulp type, mud content, fineness, concentration, etc..

- Q: The vacuum of ceramic filter is not enough

- Maybe the vacuum meter is broken. It doesn't show or show the data is different from the actual data.It could be the source of the vacuum, the vacuum pump failure.Pipeline leakage: vacuum system connecting pipes (metal pipes or rubber pipes) corrosion, aging and water leakage.Distributor head leakage: wear or poor sealing.Leakage of ceramic plate: rupture of ceramic plate.Other reasons.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

- Q: Can the ceramic plate filter the hot air?

- The cleaning of the ceramic filter is divided into two parts: reverse flushing (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board. Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure. Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.). Other reasons such as 1,2,3 are normal, but can not be discharged from the spindle speed too fast, even the ceramic filter itself manufacturing defects, the user equipment modification and so on, are likely to lead to abnormal operation of equipment. We specialize in ceramic filter boards for many years and welcome exchanges.

Send your message to us

High Silica Fiberglass Mesh Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords