Silicon Carbide Ceramic Foam Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Include:

SiC Foam Filter/CFF-01

Alumina Foam Filter/CFF-02

Zirconia Foam Filter/CFF-03

Magnesium Foam Filter (less used)

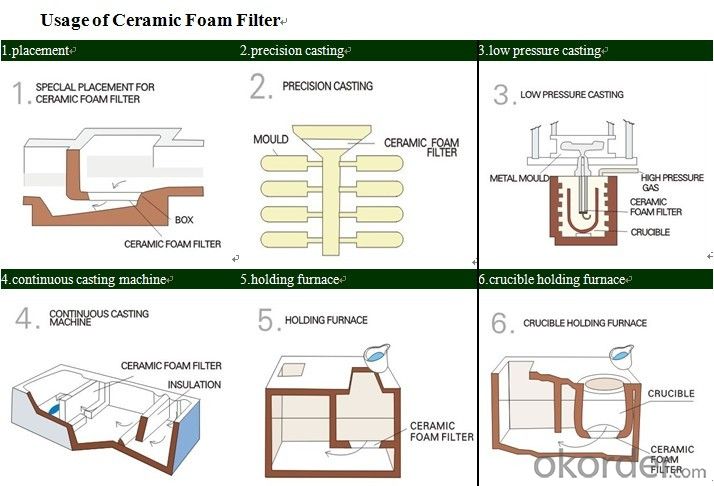

Ceramic foam filter is a kind of effective molten metal filter. It’s three-dimensional connected mesh skeleton structure and high porosity makes it has many advantages,large surface area of slags collection,large inner surface area of filtering,Small flow resistance,good filtering effect,etc.

Functions of ceramic foam filter

decontaminate the melting metal liquid,Simplified gating system,Improve casting quality rate,Reduce casting internal re-oxidation defects.Reduce the surface defects after machining of the castings

Physical and Chemical Properties

Material | Alumina | Silicon Carbide | Zirconia | Magnesia |

Color | White | Grey black | Yellow | Dark yellow |

Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | 8-60ppi |

Porosity | 80-90% | 80-90% | 80-90% | 80-90% |

Refractoriness | ≤1100°C | ≤1500°C | ≤1700°C | ≤1000°C |

Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | >0.6Mpa |

Compression Strength | >0.8Mpa | >0.9Mpa | >1.2Mpa | >0.8Mpa |

Volume-weight | 0.3-0.45g/cm3 | 0.35-0.5 g/cm3 | 0.9-1.5 g/cm3 | 0.35-0.5 g/cm3 |

Thermal shock resistance | 6times/1100°C | 6times/1100°C | 6times/1100°C | 6times/1100°C |

Application | Aluminium , Aluminium alloys and other Non-ferrous alloys | Ductile Cast Iron, Malleable Cast Iron,Gray iron and other Cast Iron | High melting point metal alloys like Steel,AlloySteel,Stainless Steel etc | Magnesium and High-Active Alloy |

For Alumina Casting

Dimensions (mm) | Dimensions (inch) | Pouring Rate (kg/s) | Filtration Capacity (ton) |

178×178×50 | 7×7×2 | 0.2-0.6 | 5 |

228×228×50 | 9×9×2 | 0.3-1.0 | 10 |

305×305×50 | 12×12×2 | 0.8-2.5 | 15 |

381×381×50 | 15×15×2 | 2.2-4.5 | 25 |

430×430×50 | 17×17×2 | 3.0-5.5 | 35 |

508×508×50 | 20×20×2 | 4.0-6.5 | 45 |

585×585×50 | 23×23×2 | 5.0-8.6 | 60 |

For Iron Casting

Dimension (mm) | Pouring Rate (kg/s) | Filtration Capacity (kg) | ||

Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

40×40×22 | 4 | 3 | 65 | 32 |

50×50×22 | 6 | 4 | 100 | 52 |

75×50×22 | 9 | 6 | 150 | 75 |

75×75×22 | 14 | 9 | 220 | 100 |

100×50×22 | 12 | 8 | 200 | 100 |

100×75×22 | 18 | 12 | 300 | 150 |

100×100×22 | 25 | 16 | 400 | 200 |

150×150×22 | 50 | 36 | 900 | 450 |

For Steel casting

Dimensi | Zirconia Foam Filter | |

Pouring Rate(kg) | Filtration Capacity(kg) | |

50×50×22 | 3~5 | 30 |

50×75×22 | 4~6 | 40 |

75×75×22 | 7~12 | 60 |

75×100×22 | 8~15 | 80 |

100×100×22 | 14~20 | 100 |

50×22 | 2~6 | 18 |

80×22 | 6~10 | 50 |

90×22 | 8~16 | 70 |

- Q: How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- Ceramic filter is a new and efficient dehydration equipment. If users find the ceramic filter board surface suction effect is poor, or even do not suck slurry, we should promptly investigate the causes, so as not to affect production efficiency.

- Q: What is the working pressure of the ceramic filter?

- The backwash pressure is the size of the backwash of the ceramic filter during recoil stage, and the recoil pressure is generally less than 0.12MPa. The greater the pressure, the better the recoil effect, the better the service life and the suction effect of the ceramic filter plate, and the worse the service life and the suction effect of the ceramic filter board. The backwash pressure of the ceramic filter shall be no less than 0.07MPa.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: Does the ceramic factory use hydrochloric acid?

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Selection of new ceramic filter plate:Because of the different size and characteristics of the pulp, different users need ceramic filter plates with different pore sizes (i.e., the average range of their surface pore size). In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.

- Q: What is the backwashing pressure of the ceramic filter?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like syringe pumping), and then through the scraper discharge, after unloading, ceramic filter machine is complete a cycle in the absorption slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles blockage will make the filter medium permeability and filtering effect of the loss from the poor, in order to reduce the possibility of blockage ceramic filter, will enter the backwash (this process is like a water jet injector). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

- Q: Can the ceramic plate filter the hot air?

- The cleaning of the ceramic filter is divided into two parts: reverse flushing (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board. Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure. Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.). Other reasons such as 1,2,3 are normal, but can not be discharged from the spindle speed too fast, even the ceramic filter itself manufacturing defects, the user equipment modification and so on, are likely to lead to abnormal operation of equipment. We specialize in ceramic filter boards for many years and welcome exchanges.

Send your message to us

Silicon Carbide Ceramic Foam Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords