Zinc Coating 80g 60g 100g 120g Color Coil Electro Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Zinc Coating 80g 60g 100g 120g Color Coil Electro Galvanized Steel Sheet

Specification of the Zinc Coating 80g 60g 100g 120g Color Coil Electro Galvanized Steel Sheet

| NAME | PPGI | GALVANIZED | GALVALUME/ZINCALUME |

| CERTIFICATE | ISO9001:2008 | ||

| STANDARD | EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653M JIS G3302 GB/T2518 EN 10142 | ASTM A792M JIS G3321 JIS G3317 EN 10215 |

| GRADE | CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 | DX51D+Z/DX52D+Z/S250GD+Z S300GD+Z/S350GD+Z/S550GD+Z SGCC/SGCH/SGCD1-SGCD3/SGC340-SGC570 G2+Z/G3+Z/G250+Z/G300+Z G350+Z/G550+Z | DX51D+AZ/DX52D+AZ/S250GD+AZ S300GD+AZ/S350GD+AZ/S550GD+AZ SGLCC/SGLCD/SGLC300-SGLC570 G2+AZ/G3+AZ/G250+AZ/G300+AZ G350+AZ/G550+AZ |

| COATING | RAL COLOURS | Z60g/m2 to Z275g/m2 | AZ30g/m2 to AZ150g/m2 |

| SIZE | (0.13mm-1.5mm)X1000mm OR as requirements | (0.13mm-4.0mm)X1500mm OR as requirements | (0.12mm-4.0mm)X1500mm OR as requirements |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled -galvanized | Hot rolled-cold rolled -galvalume /Aluzinc |

| SURFACE TREATMENT | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLER SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle,Chromate treatment /chromate-free treatment /untreated unoile/oiled,TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint,Coating | |

| APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds; Outer clad sheets for washing machine, refrigerator, televi-sion, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts; Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in high -way; Electric control cabinet, industrial refrigeration equipment, automatic vending machine; Wear resistant steel, high- strength - steel plate | ||

Supplier of the Zinc Coating 80g 60g 100g 120g Color Coil Electro Galvanized Steel Sheet

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Delivery of the Zinc Coating 80g 60g 100g 120g Color Coil Electro Galvanized Steel Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

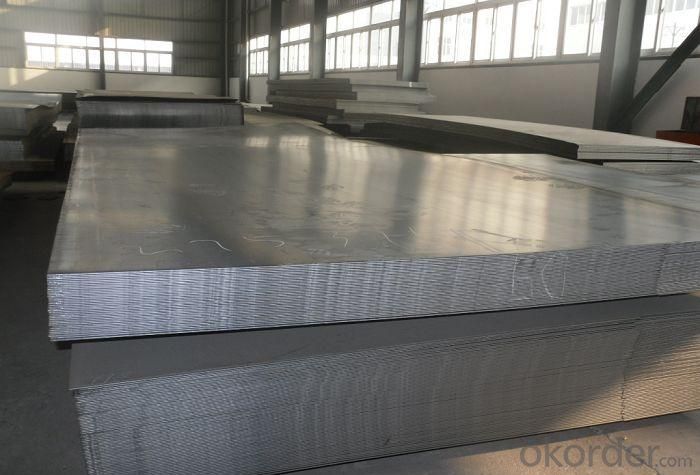

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different surface finishing methods used for special steel?

- Special steel can be subjected to various surface finishing methods, each serving a distinct purpose and yielding different outcomes. The most commonly employed surface finishing techniques for special steel comprise: 1. Grinding: By utilizing abrasive materials, grinding eliminates excessive material from the steel's surface. This method is primarily employed to attain a polished and sleek finish, while also eradicating any imperfections or roughness. 2. Polishing: By utilizing abrasive materials and polishing compounds, polishing creates a smooth and lustrous surface on the steel. This technique is frequently utilized to enhance the steel's visual appeal and bolster its resistance against corrosion. 3. Shot blasting: Shot blasting involves propelling small metallic or mineral particles onto the steel's surface at high velocities. This process effectively eliminates any impurities, rust, or scale, resulting in a clean and uniform finish. 4. Electroplating: Electroplating involves depositing a thin layer of metal onto the steel's surface via an electrochemical reaction. Commonly employed to improve the steel's appearance, corrosion resistance, and provide a decorative or protective coating. 5. Passivation: Passivation, a chemical process, entails treating the steel's surface with an acid solution to eliminate impurities and create a passive layer that resists corrosion. This method is frequently employed to enhance the corrosion resistance of stainless steel and other alloys. 6. Coating: Coating refers to the application of a protective layer or coating onto the steel's surface. This can involve utilizing paints, lacquers, enamels, or other protective coatings to prevent corrosion, enhance durability, or achieve a specific aesthetic finish. It is crucial to note that the selection of a surface finishing method for special steel heavily depends on the desired outcome, ranging from aesthetics to corrosion resistance or functionality. Furthermore, the specific characteristics of the steel, including its composition, hardness, and intended application, significantly influence the most suitable surface finishing method.

- Q: How does special steel perform in high-temperature corrosion?

- Special steel has been specifically engineered to excel in environments with high-temperature corrosion. Its exceptional properties grant it exceptional resistance against oxidation and corrosive reactions when subjected to elevated temperatures. The high chromium content found in special steel is a key factor contributing to its performance in high-temperature corrosion. Chromium creates a protective oxide layer, referred to as a passive film, which functions as a barrier against corrosive elements. This passive film remains stable even under high temperatures, successfully preventing oxidation and corrosion. Furthermore, special steel often incorporates additional alloying elements like nickel, molybdenum, and titanium, which further enhance its ability to resist high-temperature corrosion. These elements augment the steel's capacity to withstand aggressive chemical environments typically encountered in industrial processes involving high temperatures and corrosive substances. Moreover, special steel is renowned for its remarkable mechanical properties, which encompass high strength and toughness. These qualities enable the steel to endure the harsh conditions associated with high-temperature corrosion. Even when exposed to extreme temperatures and corrosive chemicals, it can retain its structural integrity and dimensional stability. In conclusion, special steel's exceptional resistance against high-temperature corrosion makes it the ideal choice for various applications in industries such as petrochemical, power generation, and aerospace. Its capacity to maintain performance and durability in challenging environments guarantees the longevity and reliability of equipment and structures, ultimately reducing maintenance and replacement expenses.

- Q: What are the different galvanizing techniques used for special steel?

- There are several galvanizing techniques commonly used for special steel, including hot-dip galvanizing, electro-galvanizing, and mechanical galvanizing. Each technique has its own advantages and is suitable for specific applications.

- Q: What are the different surface cleaning methods for special steel?

- There are several surface cleaning methods for special steel, including mechanical cleaning, chemical cleaning, and electrochemical cleaning. Mechanical cleaning involves using abrasive materials or tools to physically remove dirt, rust, or other contaminants from the steel's surface. Chemical cleaning involves using specialized cleaning agents or solvents to dissolve and remove any unwanted substances. Electrochemical cleaning utilizes an electric current and specific electrolytes to remove dirt and corrosion from the steel's surface. Each method has its advantages and is chosen based on the specific requirements and condition of the special steel.

- Q: Can special steel be used in railway applications?

- Yes, special steel can be used in railway applications. Special steel, such as high-strength steel or corrosion-resistant steel, can offer enhanced durability, strength, and resistance to wear and tear in railway components, tracks, and infrastructure. This allows for safer and more efficient railway operations.

- Q: How is free-cutting steel used in the manufacturing of screws and bolts?

- Free-cutting steel is used in the manufacturing of screws and bolts because of its excellent machinability. It contains additives such as sulfur, lead, or bismuth that improve its ability to be easily and efficiently shaped into the desired form. This type of steel enables manufacturers to produce screws and bolts with intricate threading and precise dimensions, resulting in high-quality and reliable fasteners.

- Q: What are the advantages of using special steel in specific applications?

- The advantages of using special steel in specific applications include its enhanced strength, durability, and resistance to corrosion. Special steel alloys are specifically developed to meet the unique requirements of various industries, such as aerospace, automotive, and construction. These alloys offer superior performance under extreme conditions, allowing for lighter and more efficient designs. Additionally, special steel can be heat-treated to further enhance its properties, making it ideal for applications that demand high strength and toughness.

- Q: What are the properties of electrical resistance steel?

- Electrical resistance steel, also known as resistivity steel, possesses specific properties that make it suitable for various electrical applications. This type of steel has a high resistivity, meaning it resists the flow of electrical current more than other materials. It also exhibits low electrical conductivity, making it an ideal choice for applications that require insulation or the control of electrical current. Additionally, electrical resistance steel typically has good mechanical strength, corrosion resistance, and can withstand high temperatures, making it suitable for use in electrical resistors, heating elements, and other similar devices.

- Q: How does special steel contribute to the renewable energy storage?

- Special steel plays a significant role in renewable energy storage by providing essential components for various energy storage technologies. For instance, it is used in the manufacturing of high-capacity batteries, such as lithium-ion batteries, which are crucial for storing energy from renewable sources like solar and wind. Additionally, special steel is used in the construction of wind turbine towers and solar panel frameworks, ensuring their durability and reliability. Overall, special steel contributes to the efficient and reliable storage of renewable energy, supporting the growth and sustainability of the renewable energy sector.

- Q: How does special steel contribute to the automotive industry?

- Special steel plays a crucial role in the automotive industry by providing high strength, durability, and corrosion resistance properties, which are essential for various automotive components. This type of steel is used in manufacturing critical components such as engine parts, chassis, suspension systems, and safety features like airbags and seatbelt mechanisms. It not only improves the overall performance and safety of vehicles but also helps in reducing weight, enhancing fuel efficiency, and meeting stringent emission standards.

Send your message to us

Zinc Coating 80g 60g 100g 120g Color Coil Electro Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords