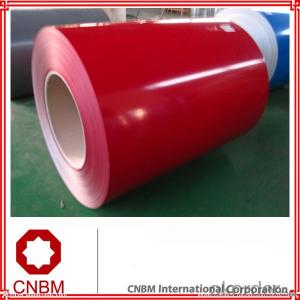

PREPAINTED STEEL COIL zinc coating 80g/m2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PREPAINTED STEEL COIL

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

PREPAINTED STEEL COIL

Technical Standard: JIS 3312

Grade:CGCC

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package: Properly packed for ocean freight exportation in 20''container

Application:: home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: What are the different types of steel coil coatings?

- Various purposes require the use of different types of steel coil coatings. Some of the most commonly used types include: 1. Galvanized Coating: This coating, based on zinc, offers excellent corrosion resistance to steel coils. It is often utilized in outdoor applications that subject the coils to harsh weather conditions. 2. Galvannealed Coating: Similar to galvanized coating, galvannealed coating also contains zinc, but it undergoes heat treatment to form an alloy with the steel surface. This type of coating provides superior paint adhesion and is frequently employed in applications where the coated coils will be painted or further processed. 3. Pre-painted Coating: As the name suggests, pre-painted coatings are applied to steel coils before they are delivered to customers. These coatings can be made of various materials such as polyester, polyurethane, epoxy, or fluoropolymer. Pre-painted coils are commonly used in the construction, automotive, and appliance industries. 4. Electro-galvanized Coating: This coating is applied to steel coils through an electroplating process, depositing a thin layer of zinc on the steel surface. Electro-galvanized coatings offer good corrosion resistance and are often employed in indoor applications or where a thinner coating is desired. 5. Aluminized Coating: Aluminized coatings involve applying a thin layer of aluminum to the surface of steel coils. This type of coating provides excellent heat resistance and is commonly used in exhaust systems, ovens, and other high-temperature applications. 6. Organic Coatings: Steel coils are typically coated with organic materials to provide additional protection against corrosion and improve aesthetics. These coatings can come in the form of paints, lacquers, or powder coatings, and they can be tailored to meet specific requirements in terms of color, gloss, and durability. In conclusion, the selection of a steel coil coating depends on the specific application, environmental conditions, desired aesthetics, and performance requirements.

- Q: How much do steel coils weigh?

- The weight of steel coils is subject to variation, which is determined by multiple factors including coil thickness, width, length, and the particular type of steel employed. In general, steel coils can range in weight from a few hundred pounds to several tons. It should be emphasized that the measurement of steel coils typically revolves around their weight per unit area, referred to as the "basis weight" or "coil weight".

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The dimensions of steel coils used in the railway equipment industry can vary depending on the specific application and requirements. However, some common dimensions for steel coils used in this industry are typically around 3 to 5 feet in width and 10 to 15 feet in length. The thickness of the steel coils can vary as well, ranging from 0.01 to 0.5 inches. It is important to note that these dimensions are not fixed and may vary based on the specific needs of the railway equipment industry, such as the type of equipment being manufactured or the specific function of the steel coils.

- Q: I know aluminum is lighter but I'm looking at a 01 bianchi grizzly mountain bike which is steel. I used to ride a specialized stumpjumper m4 which was aluminum. It was quite light so I don't know if I'll like a bit heavier bike but overall what is better from those who have had both?

- Depending on the price, aluminum may be as heavy or heavier than steel... don't let anyone tell you otherwise. Keep in mind that with age aluminum will eventually break from stress while steel will never fail due solely to riding stresses. In all, it is up to you. I ride steel or magnesium road bikes and aluminum or magnesium MTBs.

- Q: could someone please explain to me in detail the functions of stainless steel wall ties?

- wall ties are used to tie brick coursing to the back up wall...stainless steel will simply last longer than the others but you will pay dearly for them...

- Q: What are the properties of high-strength steel coils?

- High-strength steel coils possess several distinct properties that make them highly desirable in various industrial applications. Firstly, these coils exhibit exceptional strength, meaning they have a high tensile strength and can withstand significant amounts of force or weight without deformation or breakage. This property allows them to be used in demanding environments or for heavy-duty purposes. Another key property of high-strength steel coils is their excellent resistance to wear and tear. They have a high level of hardness, which enables them to resist abrasion, impact, and other forms of mechanical stress. This makes them ideal for applications where durability and longevity are crucial, such as in construction, automotive manufacturing, and machinery production. Additionally, high-strength steel coils often possess excellent corrosion resistance. They are typically coated or treated with protective materials to prevent rust or other forms of deterioration caused by exposure to moisture, chemicals, or harsh environmental conditions. This corrosion resistance property ensures the longevity and reliability of the coils, making them suitable for applications in marine environments or outdoor structures. High-strength steel coils also offer good formability, meaning they can be easily shaped or bent without losing their strength or integrity. This property allows manufacturers to create complex or custom shapes for specific applications, enhancing their versatility and adaptability. Lastly, high-strength steel coils are known for their light weight compared to other materials with similar strength properties. This low weight-to-strength ratio makes them a preferred choice in industries where weight reduction is crucial, such as aerospace or automotive manufacturing. It allows for improved fuel efficiency, increased payload capacity, and overall cost savings. In summary, high-strength steel coils exhibit properties such as exceptional strength, resistance to wear and tear, corrosion resistance, formability, and light weight, which make them valuable and versatile materials in various industries.

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped.

- Q: Does SA use its own iron ore to produce steel for construction or do we rely on imports?

- Then people like Bull tell you the country is going down yet Lakshmi and Mark Mobius(read last week's FM) show confidence in SA. Sieman, IBM and CNBC are investing millions in the country. Now who do believe?

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- S/S. We use clam rakes around here, I think they have a S/S basket with steel teeth to dig into the sand. By the way, I believe S/S is just steel with nickel added, but I could be wrong.

Send your message to us

PREPAINTED STEEL COIL zinc coating 80g/m2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords