Qualified Embossed Surface Laminated Floor Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Qualified Embossed Surface Laminated Floor Board

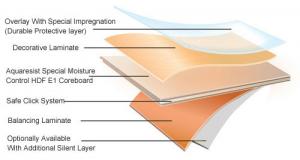

Main Structure

Technics: Laminate Flooring

Core Material: MHDF,HDF

Density: from 800kgs/m3-900kgs/m3

Grade: AC1-AC5

Clicks: single clicks, double clicks, arc clicks

Surface Finish:embossed/crystal/silk/mirror/handscraped/synchronized surface

Color: thousands of wooden colors for you to choose

packing: with paper Carton

OEM: OEM with your logo and design on paper carton

accessories: available with same color as flooring ordered

Technology Specification

Performance | Unit | Thickness(mm) |

6/7/8/11/12 | ||

Density | Kg/m3≥ | 800-900kgs/cbm |

Internal bond | Mpa≥ | 1.4 |

Internal density tolerance | ±% | 4.0 |

Bending strength | Mpa≥ | 40 |

Modules of elasticity | Mpa≥ | 3500 |

Thickness swelling | %≤ | 8.0 |

Moisture content | % | 4.0-7.5 |

Surface bond | Mpa≥ | 1.2 |

Formaldehyde release | E0≤0.5mg/L,E1≤9mg/100g,E2≤20mg/100g | |

Test Standard | GB/T17657-1999 JIS A1460 |

FAQ

1.Q:If your company have the ability to do OEM ?

A:Yes we can. For flooring cartons, we will print your LOGO and all paper carton can according to your design.

2.Q:What is the delivery time?

A:Normally our delivery time is within 15-25days after receiving your deposit or L/C. If your quantity is very big or have unnormal quality demand, we will need more time to prepare the goods

3.Q:What is your MOQ?

A:Our MOQ is one*20'container. If 8mm thickness, about 2800SQM, if 12mm, about 2200sqm.

4.Q:How many colors can you load in one container?

A:For one container we can load 3 diferent colors of laminate flooring at most.

5.Q:Can you make cartons according to our design?

A:Of course we can, pls send me your design once we confirm our order. We will send you photo of carton sample, once you confirmed OK, we will start production.

6.Q:How can I get to your city if I want to have a visit of your company?

A:3 ways arrive to us, For your reference, pls check follow picture, hope this can help you.

Picture

- Q: What are the differences and which one is better?

- Real and engineered are designed to be nailed to the subfloor.Real hard wood can be sanded and refinished more than engineered. Engineered is designed for areas that might have heat or moisture related problems.Engineered can also be only put on concrete floors by gluing it. I have put down both many times and really look and feel wise,there is no difference.The main thing is resanding and refinishing it, but most people will never even do this

- Q: I live in a condo apartment on the 2nd floor. I want to soundproof the floor, but I don't want carpeting. Therefore, I glued a cork underlayment to a wood sub floor. Now, I want to glue the engineered wood floor to the cork underlayment. Is this reccomended?

- If your cork is down well and the glue you use will bond to the cork, your ok. Check out what type of glue your using. Most urethane based glues will work. GL

- Q: In addition to the bathroom, kitchen and balcony, I would like to decorate the whole house is covered with solid wood, because I like to sit on the floor, you have a home shop wood? The weather is relatively humid in the south, it will be difficult to take care of it? Because it is too much, so I intend to fight! Ha-ha

- Keel should be used to hold a strong grip of larch, wood and other wood. The moisture content of the keel or floor should be close to the moisture content of the floor. Keel spacing should not be too large, generally not more than 30 cm. Both ends of the floor should be carried out on the keel, not empty, and each keel must be nailed on the nail. Do not use water-based glue. (6) shop floor should not be too tight around should leave enough joints (0.5 ~ 1.2 cm), and should not be laid in case of super wide, wide applications should be separated off, press the copper strip transition

- Q: What is the use of solid wood floor mopping tools

- At ordinary times, the dust can be cleaned by using a vacuum cleaner or a broom, and then the water can be dried and dried to a cloth or mop which is not dripping. After the floor is best to open windows and doors, so that the air circulation, as soon as the floor dry. Drag the wooden flooring for multifunctional electrostatic mop, including: superfine fiber cloth (wet mop cloth); magnetization (MOP) composite wood floor wear-resisting layer if the damage will make the floor moisture-proof function and brightness are affected, therefore, when walking on the floor, should try to wear cloth slippers, barefoot best. Furniture legs are affixed to the end of the soft protective pad, avoiding furniture feet scratching floor wear-resisting layer, don't let the heavy goods fell wear-resisting layer. Do not use sandpaper, sanding, steel brush, strong decontamination powder or metal tools to clean the compound wood floor. If you have a cat at home, try to solve the problem.

- Q: What is more expensive the laminate flooring or hardwood flooring? And should I get it done through lowes or home depot?

- Consumer Reports website is a great source of information for that kind of thing. You could also find good information on the Home Depot or Lowes websites. Or DIY network.

- Q: I want to decorate the house, I would like to ask how to buy real wood floor?

- Wood species selection: solid wood flooring can be simply divided into light colored material and dark material. Light color material uniform color, style and lively, can fully foil family warm atmosphere. Dark color material, the ring changes obviously, has the characteristics of smaller thermal expansion coefficient, waterproof, pest control, one of the more precious and rare, with balsam teak, Lv Bingsang, Africa pahudiaxylocarpa; good stability with wood ants (Yi Bei), jatoba, Sapele, Tully, iron hematoxylin, intsia, double column hematoxylin; wood texture clearly have Lecythidaceae wood; the color has a larger wood ants (Yi Bei), two winged beans incense; cheap, popular market Gan croton.

- Q: We are buying a house where the first floor will all be hand-brushed engineered hardwood flooring. I would like to find some kind of liner or guard that could potentially stick onto the floors directly (in the most aesthetically pleasing way) to protect it from spills of various kinds. We have a baby who is very likely to do all the spilling, so I'd prefer to avoid all the heartache proactively :) Is there a product out there that comes close to what I have in mind?

- Engineered flooring is pre finished and is usually not nailed in place. This makes it pretty much impossible to coat the floor with any additional protectant. About the best you can do is to use a rug of some kind in areas where spills are likely.

- Q: Model 8703, the solid wood floor of a plate

- Wood floor types are: solid wood flooring, laminate flooring, solid wood flooring, bamboo flooring, such as more than a dozen. To realize the choice of the kind of floor, and then have the goal to focus on the selection decision.

- Q: While laying new engineered floor boards we found some boards have a residual film after removing glue. Is there something that will remove this film without damaging the boards. We have tried wd-40, paint thinner, magic sponge.We need help floors looks baaad!! Thanks

- Try Krud Kutter available at hardware stores.

- Q: Ask the difference between solid wood composite floor and diamond plate?

- In order to integrate the advantages of the above, and now has a solid wood composite floor. Solid wood flooring: from the plates of different species cross laminated solid wood flooring, overcomes the shortcomings of single sex, dry shrinkage and wet expansion rate is small, has good dimensional stability, and retains the natural tree wood floors and comfortable feeling. Wood flooring is divided into three layers of solid wood flooring, parquet parquet, model three, to solve the deformation defects do not wear the wood floors, and feel very comfortable, but also solve the old wood floor maintenance difficult disadvantage, represents the direction of development of the wooden floor.

Send your message to us

Qualified Embossed Surface Laminated Floor Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords