Green Line Woven Polypropylene and Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Woven Geotextile Description:

Woven geotextile mainly uses polypropylene(PP),polyethylene(PE) as raw materials. After extruding.It has long term corrosion resistance in the soil and water with different PH;Due to its excellent microbiological degradation resistance. The material is light and soft, so it is convenient to transport and install.

Our product feature high tensile strength and low elongation standards. These have superior capacity for filtration and load distribution, thus reducing rutting and helping inextending the life of paved and unpaved roadways.

PP Woven Geotextile Application :

Road Construction .

Embankment on soft soils .

Slope Reinforcement .

Reclamation and breakwater .

Earth/Rock dam and irrigation infrastructures .

Railway and airfield construction .

Sport and athletic field

Anti-weeds

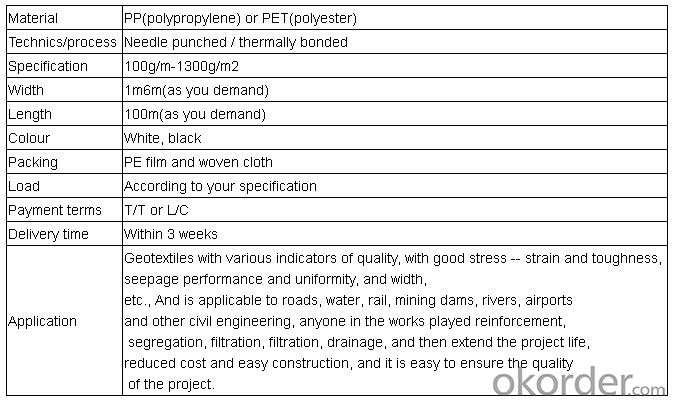

PP Woven Geotextile Specification :

PP Woven Geotextile Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by acting as a barrier between the soil and the backfill material. They prevent soil erosion and provide stability by distributing the pressure evenly across the wall. Additionally, geotextiles enhance the overall strength and longevity of the retaining wall system.

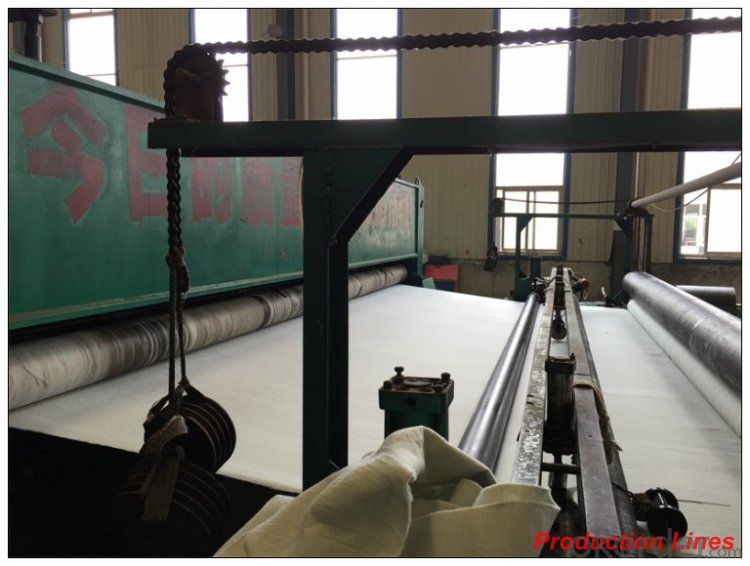

- Q: What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including weaving, knitting, and nonwoven methods. Weaving involves interlacing yarns in a crisscross pattern, creating a strong and durable material. Knitting involves interlocking loops of yarn, resulting in a flexible and stretchable fabric. Nonwoven processes involve bonding fibers together using heat, chemicals, or mechanical methods, producing a lightweight and permeable textile. Each manufacturing process has its own advantages and is used for different applications depending on the desired characteristics of the geotextile.

- Q: How do geotextiles improve the performance of geocomposites?

- Geotextiles improve the performance of geocomposites by providing reinforcement, filtration, and separation functions. They enhance the strength and stability of the composite by distributing loads and reducing soil movement. Geotextiles also prevent the mixing of different materials within the composite, ensuring efficient drainage and filtration of liquids while maintaining the integrity of the structure. Additionally, they help to control erosion and provide long-term durability, ultimately enhancing the overall performance and effectiveness of geocomposites.

- Q: Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q: Is the polypropylene composite geotextile and the polyethylene composite geomembrane the same?

- Geotextiles and geomembranes are not the same, but they complement each other to meet the engineering requirements. First introduced under the geotextile: geotextile is the state for civil engineering in the construction of a new type of construction materials, by filament or short fiber through different equipment and process shop into a mesh, and then after acupuncture and other processes to different Fibers are intertwined with each other, tangent to the fabric to make the fabric normal, so that the fabric is soft, plump, thick, stiff, to meet the different thickness to meet the requirements, according to the length of silk is divided into filament non-woven geotextile or short wire Non-woven geotextile, filament tensile strength higher than the short wire. Fibrous soft with a certain tear resistance. The main role is: filter, filter, reinforcement role. Specifications from 100 grams per square meter to 800 grams per square meter. The main material for the polyester fiber, with excellent permeability, filtration, durability deformation adaptability, and has a good flat drainage capacity (see below) Geomembrane to plastic film as anti-seepage substrate, and non-woven composite Made of geotextile impermeable material can be divided into two cloth a film, a cloth a film, its impermeability depends mainly on the plastic film impermeability. The geomembrane is a waterproof barrier material with the polymer of the polymer chemical material as the basic raw material. The proportion of small, strong extension, high adaptability to adapt to deformation, corrosion resistance, low temperature, good frost resistance. (See below)

- Q: What are the design considerations for geotextile applications?

- Some of the key design considerations for geotextile applications include the type of geotextile material to be used, the required strength and durability, the desired permeability and filtration properties, the potential for installation damage or degradation, and the compatibility with other materials and environmental conditions. Additionally, factors such as site-specific soil characteristics, water flow rates, loadings, and the intended function of the geotextile also need to be taken into account during the design process.

- Q: Basically I'm thinking of doing a thesis defense on this topic and I want to know if it is any good.

- Any bio-degradable material is not a better substitute for a geotextile material in long run Materials from polymer family may suit better, like Polyamide Polypropylene Polyethylene My answer refers to about having the ability to separate, filter, reinforce, protect, or drain If your purpose of using geotextile material regarding Beach Erosion, Riverbank Erosion, then coconut fibers is a better option

- Q: What are the specifications for geotextiles and geogrids commonly used on expressways?

- You are the production, or sales, or procurement, the question asked, what model is the designer's decision

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by providing a physical barrier that stabilizes soil and prevents its movement. These permeable fabrics allow water to pass through while trapping soil particles, thereby reducing surface erosion. Additionally, geotextiles improve soil stability by reinforcing it, preventing its displacement and aiding in the establishment of vegetation.

- Q: How do geotextiles help with reinforcement of geogrid reinforced soil slopes?

- Geotextiles help with the reinforcement of geogrid reinforced soil slopes by acting as a separator and filter between the soil and the geogrid. They prevent the soil particles from passing through the geogrid openings, maintaining its stability and preventing the loss of soil material. Additionally, geotextiles distribute the load and stress evenly across the geogrid, enhancing its load-bearing capacity and overall performance in reinforcing the soil slope.

Send your message to us

Green Line Woven Polypropylene and Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords