Eco-friendly Geotextile Fabric, Polypropylene Woven Fabric

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Eco-friendly Geotextile Fabric, Polypropylene Woven Fabric

Desciriptions:

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

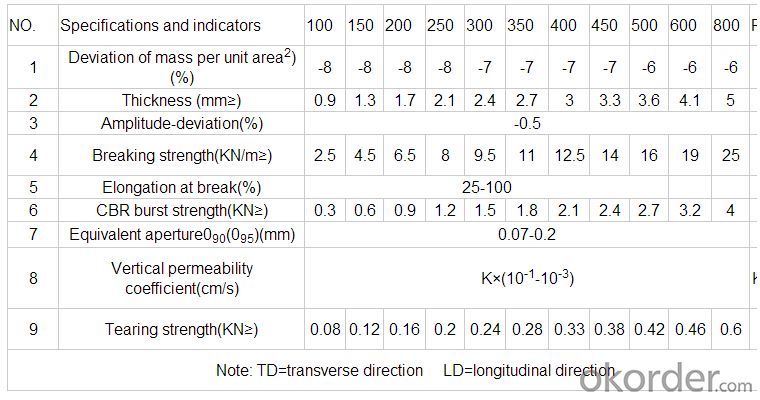

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

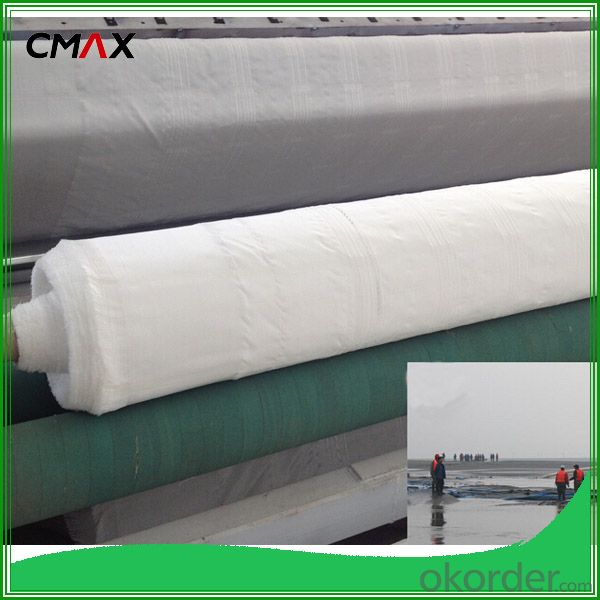

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help in reducing soil compaction?

- Geotextiles help in reducing soil compaction by distributing the load from heavy vehicles or equipment over a larger area, thereby minimizing the pressure exerted on the soil. This prevents the soil particles from being compressed tightly together, allowing for better soil structure and drainage.

- Q: How do geotextiles contribute to groundwater recharge projects?

- Geotextiles contribute to groundwater recharge projects by acting as a filtration and drainage system. They allow water to pass through while retaining sediment, preventing clogging of the recharge basins or infiltration trenches. This helps to enhance the recharge process, allowing more water to percolate into the ground and replenish the groundwater.

- Q: How do geotextiles improve the performance of pavement structures?

- Geotextiles improve the performance of pavement structures by providing separation, filtration, and reinforcement. They prevent the mixing of different soil layers, allowing each layer to function independently and efficiently. Geotextiles also act as a filter, preventing the clogging of underlying drainage systems by allowing water to pass through while retaining the soil particles. Furthermore, they reinforce the pavement, distributing the load more evenly and reducing the potential for rutting and cracking. Overall, geotextiles enhance the durability, stability, and longevity of pavement structures.

- Q: How are geotextiles manufactured?

- Geotextiles are manufactured through a process called needle-punching, where synthetic fibers such as polyester or polypropylene are mechanically interlocked together using needles. This method creates a strong and durable fabric with various applications in civil engineering, landscaping, and erosion control.

- Q: How do geotextiles help with ground reinforcement?

- Geotextiles help with ground reinforcement by providing a strong and stable support system. They are typically made of synthetic materials and are placed beneath the ground surface to distribute the load and prevent soil erosion. The geotextiles act as a barrier, allowing water to pass through while retaining soil particles, which helps in maintaining the stability of the ground and preventing any potential damage or failure.

- Q: What is the standard width of geotextile?

- Geotextiles do not have a standard width requirement. The geotextile width is now between 2 and 8 meters. Different geotextiles, the width of the different, even if the same geotextile, there are different width. Geotextile width of the width of some of the actual use of less than some of the joints, the construction speed can be faster, more quality of the project to ensure that some. But it can not be too wide, transport and construction tools will have an impact. Can be in accordance with their actual needs to determine the actual construction.

- Q: How are geotextiles recycled?

- Geotextiles can be recycled through a process called mechanical recycling. This involves collecting used geotextiles, cleaning them, and breaking them down into smaller fibers or pellets. These recycled materials can then be used to manufacture new geotextiles or other products, reducing the need for raw materials and minimizing waste.

- Q: Whether the reservoir is geotextile or geomembrane is good

- Composite geomembrane and geomembrane can be. Detailed consultation to see the information

- Q: 300 grams of non-woven geotextile piercing strength is how much

- First of all, according to what you said 300g non-woven geotextile should be polyester staple fiber non-woven geotextile. Polyester staple fiber non - woven geotextile implementation of the national standard GB / T - 2008 standard. According to GB / T-2008 standard anti-puncture strength (standard is CBR burst strength) requirements, 300g national standard geotextile anti-piercing strength should be ≥ 1.5KN.

Send your message to us

Eco-friendly Geotextile Fabric, Polypropylene Woven Fabric

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords