Aluminum Diamond Deck Sheets - Woodgrain Coated Aluminum Sheets for Rolling Gutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Woodgrain Coating Aluminum Sheets for Rolling Gutter Doors

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Woodgrain Coating Aluminum Sheets for Rolling Gutter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Woodgrain Coating Aluminum Sheets for Rolling Gutter Doors

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

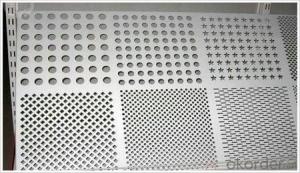

5. Image of Woodgrain Coating Aluminum Sheets for Rolling Gutter Doors

6. Package and shipping of Woodgrain Coating Aluminum Sheets for Rolling Gutter Doors

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to many chemicals. Aluminum has a natural oxide layer on its surface that provides a protective barrier against corrosion and chemical reactions. This oxide layer is stable and resists most acids, alkalis, and organic solvents. However, aluminum can be corroded by certain chemicals, such as strong acids or bases, and some halogenated compounds. Additionally, prolonged exposure to certain chemicals or extreme conditions may weaken the oxide layer and make aluminum more susceptible to corrosion. Therefore, while aluminum sheets are generally resistant to chemicals, it is important to consider the specific chemical environment and potential interactions before using aluminum in certain applications.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes through a process called extrusion.

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet strongly influences its mechanical properties. The mechanical properties of aluminum sheet can include tensile strength, yield strength, elongation, hardness, and fatigue strength, among others. Firstly, the alloy composition affects the overall strength of the aluminum sheet. Aluminum alloys are typically mixed with other elements such as copper, manganese, magnesium, and silicon to enhance their mechanical properties. These alloying elements form solid solutions or precipitates within the aluminum matrix, which can significantly increase the strength of the material. For example, adding copper to aluminum forms a solid solution that increases the tensile strength and yield strength of the sheet. Secondly, the alloy composition affects the ductility and formability of the aluminum sheet. Some alloying elements, such as magnesium and silicon, can reduce the ductility of aluminum alloys. This reduction in ductility can make the sheet more prone to cracking or fracturing under stress. On the other hand, certain alloying elements can improve the formability of aluminum sheet, making it easier to shape or bend without cracking. Furthermore, the alloy composition also influences the resistance to corrosion and heat of aluminum sheet. For instance, aluminum alloys with a high content of magnesium, such as the 5000 series, exhibit excellent resistance to corrosion and are commonly used in marine applications. Additionally, some aluminum alloys are developed specifically for high-temperature applications, with alloying elements like copper and zinc enhancing their heat resistance. Lastly, the alloy composition of aluminum sheet affects its microstructure, which in turn affects its mechanical properties. Different alloy compositions can result in different microstructures, such as grain size, grain boundaries, and phase distribution. These microstructural features can affect the strength, hardness, and fatigue resistance of the aluminum sheet. In conclusion, the alloy composition plays a crucial role in determining the mechanical properties of aluminum sheet. By carefully selecting the appropriate alloy composition, manufacturers can tailor the sheet's properties to meet specific requirements, such as strength, ductility, formability, corrosion resistance, and heat resistance.

- Q: What type of aluminum plate does it contain?

- 1 * * * series aluminum sheet: stands for 1050, 1060, 1100. In all series, the 1 x x series belongs to a series with the largest amount of aluminum. Purity can reach more than 99%.2 * * * series aluminum sheet: 2A16 (LY16) and 2A06 (LY6). The characteristics of 2 * * * series of aluminum is high hardness, which belongs to the copper content is the highest, about 3-5%.

- Q: What are the maximum dimensions of aluminum sheets?

- The maximum dimensions of aluminum sheets can vary depending on the manufacturing capabilities of different suppliers. However, in general, aluminum sheets are available in a wide range of sizes to meet various application requirements. Commonly, the maximum width of aluminum sheets can be up to 72 inches (6 feet), while the maximum length can reach around 240 inches (20 feet). These dimensions can provide ample material for a wide range of projects, including construction, manufacturing, and industrial applications. It is important to note that specific suppliers may have their own limitations, so it is advisable to consult with them directly to determine the maximum dimensions available for aluminum sheets.

- Q: Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- A high end aluminum frame would be a better choice than a mediocre carbon frame. Aluminum frames are light, and a good one could well be lighter than a lower end carbon frame. Stiffness is an overrated quality in a frame. A frame that is unrelentingly stiff can beat you up and be a chore to ride. Good frames are stiff where they need to be and compliant in the right places to make them comfortable to ride. Cannondale was one of the first companies to start building quality aluminum frames for road bikes, before any of the other major bike companies on the market today, and they continue to sell high end aluminum bikes today. Early aluminum frames had durability issues, but those problems have been resolved. Frame weight is not much of an issue. Keep in mind that the rest of the components of a bike weigh far more than the frame. You can't turn a 25 pound bike into a 15 pound bike with a better frame, the difference in weight between a top level carbon fiber frame and an aluminum frame will be much less than 1 pound, even a good steel frame will weigh less than 2 pounds more than the lightest carbon frames.

- Q: This question asks about the typical duration an aluminum roof sheet can last before it needs to be replaced or repaired.

- <p>The lifespan of aluminum sheets for roofing can vary depending on the quality of the material, installation, and environmental factors. On average, a well-maintained aluminum roof can last between 20 to 50 years. High-quality aluminum roofing materials, when properly installed, can even exceed this range, offering a lifespan of up to 70 years. However, it's important to note that regular inspections and maintenance are crucial to extend the life of any roofing material, including aluminum.</p>

- Q: Are aluminum sheets suitable for heat exchangers?

- Yes, aluminum sheets are suitable for heat exchangers. Aluminum is a highly conductive metal, which allows for efficient heat transfer. Its lightweight nature makes it easy to handle and install in heat exchanger systems. Additionally, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the heat exchanger. Furthermore, aluminum sheets can be easily formed into different shapes and sizes, making them customizable for various heat exchanger designs. Overall, aluminum sheets offer excellent thermal conductivity, corrosion resistance, and versatility, making them a suitable choice for heat exchanger applications.

Send your message to us

Aluminum Diamond Deck Sheets - Woodgrain Coated Aluminum Sheets for Rolling Gutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords