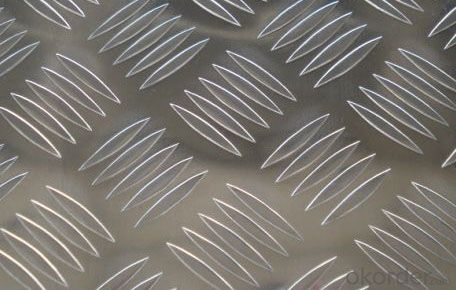

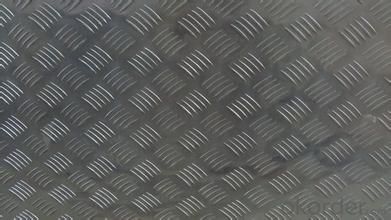

Diamond Aluminum Sheets - 1 Series Aluminum Alloy Sheet for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

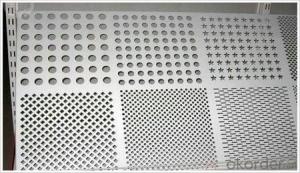

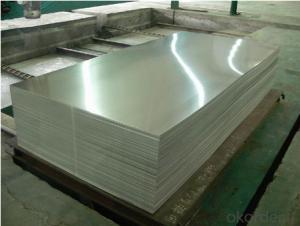

Specification

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- Aluminum wiring contracts and expands more than copper wiring of similar size. This means that it has a tendancy to loosen the screws on the outlets over time. As the screws loosen, the resistance in the circuit goes up - this resistance manifests itself as heat. If it gets too hot, it can start fires. My parents owned a house with aluminum wiring, that they sold to me. In the 35 years total we've owned it, I think we've tightened the screws on the outlets three times total. Only once in all that time have we had a wall get hot. The most recent tightening was during a major repainting where we actually replaced the outlets and switches with decorator ones as we painted each room.

- Q: Can the aluminum sheets be used for insulation purposes?

- Aluminum sheets have the ability to serve as insulation material. Due to its high thermal conductivity, aluminum can effectively hinder the transmission of heat between two surfaces. For instance, aluminum sheets can be utilized as a reflective shield within walls, roofs, or floors to minimize heat transfer by reflecting radiant heat. They can also act as a vapor barrier, preventing the ingress or escape of moisture in a given space. Furthermore, aluminum sheets can be incorporated into an insulation system, combining them with other insulating materials like foam or fiberglass to augment their thermal insulation properties. In conclusion, aluminum sheets deliver efficient insulation and contribute to energy efficiency in buildings.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Indeed, the utilization of aluminum sheets is possible in the production of heat exchanger fins. Owing to its remarkable thermal conductivity and resistance to corrosion, aluminum stands as a frequently employed substance in heat exchangers. The lightweight and easily malleable attributes of aluminum sheets render them exceptionally suitable for the creation of fins that possess an extensive surface area, thereby augmenting heat transfer. Furthermore, aluminum is readily accessible and cost-efficient, solidifying its status as a favored selection within the realm of heat exchanger manufacturing.

- Q: I'm making a project for class and I bought a 10 Inch long 5mm thick aluminum/metal, How do you cut it WITHOUT large machinery? is there any power tools adapters or tools that can do this job without a problem?Here is what I have to do:*Cut the metal into ~1x1 and 2X2inch squares*Somehow shave a circle about 2mm deep without going trough the 5mm aluminum (Shaded gray)*Drill a hole right through the 5mm (right in the center)*Drill screw holes on each cornerI provided a really basic pic of what I'm trying to dohttp://img204.imageshack.us/img204/487/77845398.pngRED=backgroundGRAY=drilled 2mm deep WITHOUT GOING THROUGHRED HOLES=screw holes with threadsPlz help need to finish this by friday!PS: Screw holes, and other sizes don't matter right now I'm just trying to figure out what tools/tool adapters I need thanks!

- The through holes are no problem. A standard drill with the appropriate drill bit and thread taps will do the job nicely. The 2mm deep cavity presents a problem. You need at minimum, a face cutting (facing) bit for aluminum and a drill press. This operation can go wrong very quickly, so I suggest you cut the 2mm cavity before you cut the piece into a square. The bit can be purchased at a machine tool supply company. If there's a Harbor Freight store in your area, they might have what you need. Set the drill press on a lower speed and use a gentle pressure feeding the bit into your work. The piece needs to be tightly clamped to the drill press platform before starting. Any movement of the piece or grabbing by the facing bit can ruin your work and/or cause personal injury. As for cutting the piece, if you can find a set of power squaring shears, that would be the best. Otherwise, opt for a metal saw blade for soft metals and a table saw. Of course you will need to deburr and smooth all your cuts. A mill file should do the job nicely. Have a file card handy for cleaning the file. Aluminum, copper, and other soft metals load up files quickly. The most important thing to remember when working with metals is that a gentle and steady hand works best. Let the tool do the work. If you collect all your resources within the next couple days, you could turn out one per hour. I don't know how many of these you need. Good luck.

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are suitable for signage. They are lightweight, durable, and weather-resistant, making them a popular choice for outdoor and indoor signage applications. Additionally, aluminum sheets can be easily customized, printed, and mounted, allowing for versatile and long-lasting signage solutions.

- Q: Can the aluminum sheets be used for manufacturing food storage containers?

- Indeed, food storage containers can be manufactured using aluminum sheets. The utilization of aluminum in food storage containers is widespread due to its qualities such as being lightweight, long-lasting, and possessing exceptional thermal conductivity. Its malleability allows for effortless shaping into diverse dimensions, making it adaptable for various storage requirements. Moreover, aluminum exhibits resistance to corrosion and can be conveniently cleansed, guaranteeing the protection and cleanliness of the stored food.

- Q: What are the weight-saving benefits of using aluminum sheets in different applications?

- Using aluminum sheets in various applications offers several benefits for weight-saving. Firstly, aluminum is a lightweight metal with a density much lower than commonly used materials like steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in different applications. The reduced weight of aluminum sheets is especially advantageous in transportation industries. For instance, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the overall weight of vehicles. This weight reduction leads to improved fuel efficiency as it requires less energy to move the lighter vehicle. Additionally, lighter vehicles generally exhibit better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every additional kilogram of weight on an aircraft can increase fuel consumption and operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. The construction sector also highly values the weight-saving benefits of aluminum sheets. Due to their lightweight nature, aluminum sheets are often used in building and infrastructure construction. This characteristic not only makes installation easier but also reduces the load on the building's foundation. Moreover, using aluminum sheets in construction can lead to cost savings as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. Aluminum's lightweight nature allows for weight reduction in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings, and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets provide a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

- Q: Can aluminum sheet be used for automotive applications?

- Yes, aluminum sheet can be used for automotive applications. It is commonly used in the manufacturing of car bodies, hoods, doors, and other structural components due to its lightweight, corrosion resistance, and high strength-to-weight ratio.

Send your message to us

Diamond Aluminum Sheets - 1 Series Aluminum Alloy Sheet for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords