Wood Plastic Composite Wall Panel WPC Cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

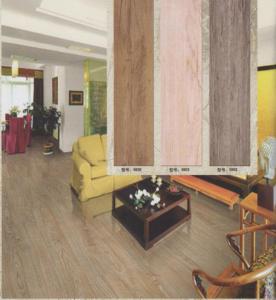

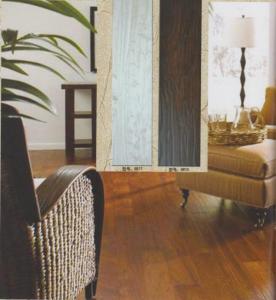

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

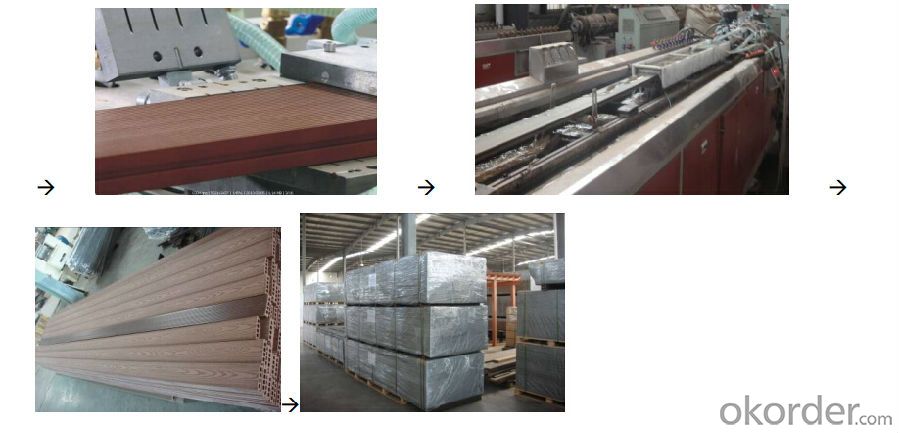

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

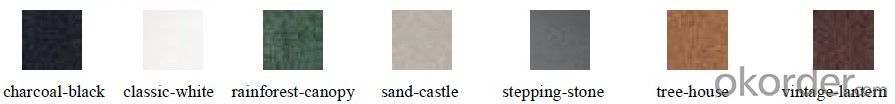

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

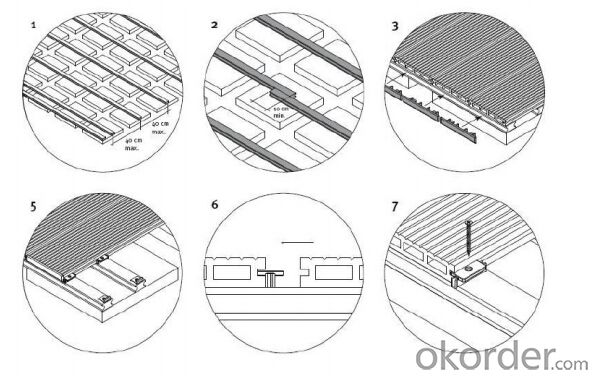

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q: The kind of water used in the hospital is that it can be washed with water, and it is very thin and very light. The surface is made of stone.

- Epoxy floor paint, it can be made as a whole, waterproof wear.

- Q: How to clean the composite wood floor?

- Composite wood flooring maintenance of composite wood flooring method is very simple. Usually you can use a vacuum cleaner or a broom to clean the surface dust, and then wipe the floor with a wiping or a mop that is wiped and wiped. After the first open the doors and windows, so that air circulation, as soon as possible to dry the floor. Composite wood floor wear layer if the damage will make the floor of the moisture-proof function and brightness affected, therefore, walking on the floor, should try to wear slippers, the best barefoot. To the furniture feet are affixed to the soft bottom of the protective pad, to avoid the furniture feet scratched floor wear layer, do not let heavy objects smashed wear layer. Can not use sandpaper, sander, steel brush, strong decontamination powder or gold attack penalty board nuclear microphone Gui Tai Tai coffee tools to clean up the composite wood flooring. If the cat at home, to find ways to solve the cat claw damage. Here to introduce a clean light-colored composite wood flooring tips: with a rag dipped in Taomi Shui directly on the floor to wipe, or Taomi water evenly sprayed on the wooden floor (not too much), 5 minutes with a dry cloth to wipe, The floor will clean up a lot. Cleaning of special stains: oil stains, paint, ink can be used to wipe the special stains; blood, fruit juice, red wine, beer and other residual stains with a wet cloth or wiped with an appropriate amount of floor cleaning agent wipe; wax and chewing gum, Put on the above for a while, so that the frozen contraction, and then gently blowing, and then wipe with a damp cloth or wiped with an appropriate amount of floor cleaning agent wipe. Do not use strong acid-base liquid cleaning wood flooring. More little knowledge can be found on the website of Jing Guang Huayi Company.

- Q: What is a laminate flooring AC rating?

- Depends on which laminate floor you're talking about. Like most things laminate floors are NOT all created equal, some are much, much better than others. The different manufacturers should have that information available.

- Q: Is it neccessary to prime the floor of an insulated garage before repainting?

- When it comes to painting Garage floors , follow every trick in the book, getting a good permanent adhesion is the hardest part, so do everything your paint manufacturer recommends. Select a paint that is recommended for GARAGE FLOORS! Here are the basics to make sure it lasts.Steam clean the floor of all oil spots. If the floor has smooth finish, rough it up before Priming. Prime using 2- light coats wait 24-hrs. between coats. It will be 3-days before you can drive on it. If youe just must drive on it sooner put carpeting in the path of the vehicle, to stand on.

- Q: I put in ceramic tiles on my first floor like 800 sq feet of it .. anyways i have 2 kids and 2 dogs i was wondering about buying a floor scrubber like one that scrubs and picks up the water afterwards because mopping just doesnt cut it.. what brands do you use or what advice would you give for cleaning these floors other than mopping them every other day!! thanks!!

- I would suggest preventing the dirty floor...less time spent washing. Perhaps you're already doing the following, but if not, these are things that helped me... When our dogs come in, and if it's been wet out, we have an old towel to dry off their feet. If there feet are muddy, we have a warm wet rag to clean off the mud, and then we dry their feet. We have the towel and/or rag waiting at the front door. The kids...eat only at the table. Spills made by anyone are wiped up immediately. No shoes in the house. Vacuum the floors every/every other day. I wash my floors every 4-7 days. I wash all my floors on my hands and knees with a rag, and liquid cleaner, added to hot water. This is the the best way to get your floors clean. Good luck to you!

- Q: I pulled up all the carpet in my bedroom, and some areas in the hardwood floor is darker then some other places. What can I do to make the floor bright again?

- The best option is to have it refinished. You can do this yourself or have it done. It will be sanded down to bare wood, stained if desired, then 3+ coats of polyurethane will be applied. This will make the floors look like new, and protect them for a long time. Good luck.

- Q: would sanding floor correct ridges in hardwood floor that happened when contractor tried to correct buckling floor.did' he do poor workmanship but would sanding help.thank you

- This factor usually happens when the foundation floor is not straight , if someone could add extra support from the basement this will even up the floor above, whoever installed your floors was probable off level when they did so, and the only way to fix this would be to remove the boards and work with the sub floor, but .....that's too much work and an extra expense to you unless you still have a valuable warranty , I wouldn't bother otherwise. .

- Q: Would you like to be able to shop with stone flooring?

- Stone floor is PVC sheet flooring, so from the material point of view, it is closer to the tiles, single from the thermal performance point of view, but it is slightly worse than the composite floor, as to whether it is suitable for heating, from the following two aspects Analysis: 1. If the water is installed to warm, then the impact on the floor is not great, choose stone floor is possible. Just the beginning of the time, the floor will be hot some slow, so the temperature of the whole room are up after, there is not much difference. 2. If you are equipped with electric heating, then have to see whether the family has been someone. If someone at home, to warm long-term operation at a higher temperature, then what the floor floor are the same. But if no one day only go back at night to increase the temperature to warm, then you should choose a good thermal conductivity of the floor, reducing the temperature adjustment caused by the loss of heat. Stone floor of the impact of warm heat in the 10% to 30%, is not conducive to energy conservation, and stone floor of the cooling effect is not very obvious. Therefore, the floor is warm can be paved stone floor, but from the perspective of economic and environmental protection to start the case, it is not recommended that we use stone floor.

- Q: if this helps my laminate floor is not cheap

- I okorder /

- Q: My bedroom is 110 Sq Feet(11 ft by 10 ft)I want to get floating floors-Preferable Aluminum Oxide (sp?) finish, hard surface.And if you can provide, what is the cheapest cost and where can i find it?-Pref. from someone who has purchased floating floors.Thank you.

- I have installed most types of wood flooring including hardwood ,veneer, etc. whether glued, nailed or floating. Unless you live in a humid area or your bedroom is in the basement, I recommend you get flooring that can be glued or nailed down. I have seen even very expensive/professionally installed, floating floors break their seams (move apart). Price is relative, but you get what your pay for. If you put down the cheapest flooring you can buy, you are throwing your money away. I would also suggest that you avoid an aluminum oxide finish. It can ONLY be refinished by a professional, and at a higher cost than a time proven polyurethane finish, which is hard enough for any residential application.

Send your message to us

Wood Plastic Composite Wall Panel WPC Cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords