synthetic wood flooring/wpc decking FROM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

synthetic wood flooring/wpc decking From China

一.Product Description:

synthetic wood flooring/wpc decking From China

High Quality Supplier Looking For Partner

35% HDPE (Grade A Recycled HDPE),

55% wood fiber (Professionally treated dry wood fiber),

10% chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants...etc.).

Features

1.Looks and feels like nature wood

2. Waterproof, Mildew-resistant

3.Anti-High degree of UV and colour stability

4. No hazardous chemicals,100% recycle,Environmental friendly,Saving forest resources

5.weather resistant,Suitable from -40'C to 60'C

6. Easy to install and clean

7. Unaffected by termites and other insects, rodents,worms or marine parasites

8. Low maintenance cost

9. Anti-slip, less cracking, less warping

High Quality Supplier Looking For Partner

35% HDPE (Grade A Recycled HDPE),

55% wood fiber (Professionally treated dry wood fiber),

10% chemical additives (Anti-UV agent, Anti-oxidation agent, stabilizer, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants...etc.).

Features

1.Looks and feels like nature wood

2. Waterproof, Mildew-resistant

3.Anti-High degree of UV and colour stability

4. No hazardous chemicals,100% recycle,Environmental friendly,Saving forest resources

5.weather resistant,Suitable from -40'C to 60'C

6. Easy to install and clean

7. Unaffected by termites and other insects, rodents,worms or marine parasites

8. Low maintenance cost

9. Anti-slip, less cracking, less warping

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

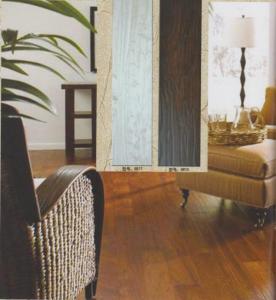

四. More picture for your reference

- Q: what should you use on a cement floor that has been painted with paint. spray paint gloss finish or floor wax. ?

- Hi Ucleremuss, I’m Blake, I work for Home Depot out in California. For a concrete floor that has been spray painted I would highly recommend going with a more durable protective option than wax. We offer many different types of Urethane floor protectants that will give you the most life out of that paint. They come in gloss or satin sheens. Although wax provides good water resistance, it does little to protect the floor from wear and tear. Urethane will actually provide a rigid armor-like coating for the more brittle spray paint. I hope this helps! -Blake @ The Home Depot

- Q: outside our shower the floor has gotten wet some, and over time it has begun to wet the floor. now, the floor creaks some, and i think the particle board has gotten wet underneath. is there any way to dry this or help to remedy this process without actually replacing the floor? thanks

- Sorry, but if it’s particle board and it has gotten wet over time …..most likely it is ruined

- Q: Solid wood composite floor with enhanced floor than, which is good?

- Solid wood flooring to better point but to pay attention to both the formaldehyde content and free formaldehyde emission is up to standard

- Q: We have a BIG island in our kitchen and an empty wall behind it.Our flooring is a laminate type. We want to remove the island and put a row of cabinets along the wall. My questions are: Are cabinates installed on top of the laminate flooring? If not, how do we remove the flooring along the wall and possibly use those boards to patch the spot where the island was? We really Hate this island. Any help would be greatly appreciated.

- Look at where the island and laminate meet. Does it look like the laminate goes under or is their molding at the base of the island. I would also guess that the laminate goes around the island. Laminate boards connect on the ends as well as the sides. You willl not simply be able to insert board to filll the hole, to do it right you will have to reset the boards the entire length. Also, what are you going to do to replace the laminate that you pull off that is against the wall? Sorry to be a pain but i just wanted to know what you are up against before ridding yourself of the island.

- Q: I've been using the laminate floor spray with a swifter type mop thingy but the floors aren't coming out as clean as I'd like.

- It works great, and your floors will shine!

- Q: When you replace carpet in a room because you want to install hardwood... do you need to replace the subflooring? Do you replace sub flooring every time you replace flooring?

- Usually as R T said if it's in good condition you can leave it like that which should be under normal use, but I do suggest you to seal it if it is not and depending on how many years since it was originally install that carpet, maybe reapply seal is it has it.

- Q: Is floor(x k) = floor(x) floor(k)?

- yes it is fallowing the distributive property

- Q: My parquet floor is expose to water and moisture due to rain water getting on them. Resulting with small 'polka dots' like damage on the surface. Is there any way that I can DIY repair it? Cos getting the professionals are too expensive.

- Parquet floors are easily damaged by exposure to moisture. There is a point where you can't fix them, they have to be replaced. Ask again with pics of the floor for a better answer.

- Q: -for a concert-i wanna be close to the stage, but ive heard that unless ur in the first few rows, u cant really see anything on the floor. how many rows back are they worth it? would it be better to just get level 1 seats? opinions?? thanks. im like 5&

- I had a somewhat bad experience with floor seats. My wife and I went to see Trans-Siberian Orchestra and we shelled out for the floor seats. I don't know if it was the height of the stage or what, but it was really hard to see sometimes. I'm 6' and even I had trouble seeing over everyone in front of me. All that said though, it was still fun. We were more involved in all the neat theatrics of the show and felt a lot closer to the action. I would still say it was worth it though because once the show really got going the performers were all over the place so you get some good views.

- Q: How thick must the floor be over the joists? Does the thickness include the floor covering (tile)?

- The spacing of the joists dictates the thickness of the floor decking wood. Common is 16 in on centrs. but others will alter that. No your structrual thickness is only based on the structrual material. In your case the plywood. About 25 years ago; a common practice was a 1/2 in sub floor. then a 5/8 in underlayment over. That was dropped do to cost as well as newer floor decking products became available. Today probably 99% construction is a 3/4 in. tongue and groove, some call sturdy floor applied to 16 in on centrs. Plywood products have stamps on them that indicate floor joist spacing and roof rafter spacing. The smaller number would be for the floor spacing.

Send your message to us

synthetic wood flooring/wpc decking FROM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords