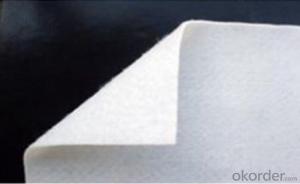

Geotextile Nptel White Isolation Non-Woven Geotextile Fabric for Road, Custom Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Features & benefits

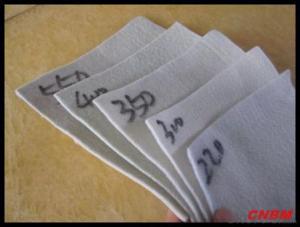

Mass per unit areas range from 100g to 800g/m2 to guarantee an available product for every application (heavier products may be available by special order)

Superior chemical resistance in even the most aggressive environmental applications

Continuous long fibers needle punched together to form a sturdy fabric capable of withstanding construction installation stresses

Contains additives for maximum UV resistance

You may also interested in other products

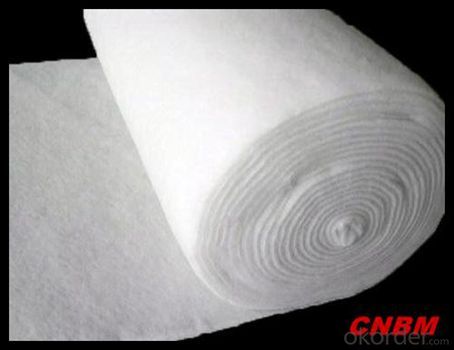

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: What are the specifications for geotextiles in roadways?

- Geotextiles used in roadways should meet certain specifications to ensure their effectiveness. These specifications typically include factors such as tensile strength, puncture resistance, filtration capability, and elongation properties. Additionally, the geotextiles should have appropriate thickness, weight, and permeability to allow for proper drainage and filtration of water. The specifications may vary based on the specific requirements of the road project, but overall, geotextiles in roadways need to be durable, efficient, and capable of enhancing the overall performance and longevity of the road.

- Q: Geotextile packaging what are the requirements

- Geotextile packaging requirements are as follows: 1, staple acupuncture non-woven geotextile according to set into a long volume of packaging. The fixed length shall be determined in accordance with the product specification or the parties concerned. 2, the product of the splicing rate should be less than 15%, the total length of each piece of stitching products should be 7.1.1 fixed length plus 1m or more, every 100m to allow splicing 2, or by the supply and demand sides to determine. 3, the length of the product in the 30m below a small package can be a separate package, for a head treatment, 4, product packaging should ensure that no scattered, no damage, no pollution. Users have special requirements, the supply and demand sides to determine the consultation.

- Q: Are geotextiles resistant to mold and mildew?

- Yes, geotextiles are generally resistant to mold and mildew due to their synthetic composition and the fact that they do not retain moisture.

- Q: Can geotextiles be used in retaining wall reinforcement?

- Yes, geotextiles can be used in retaining wall reinforcement. Geotextiles are often used as a separation and filtration layer in retaining walls to prevent soil erosion and improve their stability. They can help distribute loads, reduce soil movement, and enhance the overall performance and durability of the retaining wall system.

- Q: Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: How are geotextiles used in landfills?

- Geotextiles are used in landfills as a protective barrier or liner, preventing the contamination of soil and groundwater by acting as a barrier between the waste and the underlying natural environment. They help to control the flow of liquids, filter out pollutants, and provide stability to the landfill structure, ultimately enhancing environmental protection and the longevity of the landfill.

- Q: What are the factors to consider when selecting geotextiles for mining applications?

- When selecting geotextiles for mining applications, factors to consider include the type and size of particles being contained or separated, the required strength and durability of the geotextile, the level of permeability needed, the potential for chemical or biological degradation, and the site-specific conditions such as slope stability and groundwater levels. Additionally, the cost-effectiveness and ease of installation should also be taken into account.

- Q: How do geotextiles help in preventing soil compaction?

- Geotextiles help in preventing soil compaction by acting as a barrier between the ground and heavy machinery or vehicles. They distribute the weight more evenly, reducing the pressure on the soil and minimizing compaction. Additionally, geotextiles improve drainage and allow air circulation within the soil, which further helps in preventing compaction.

- Q: Geotextile strength index with interpolation method how to calculate? Then geotextile variation, I do not quite understand, pro, if you know whether to tell me Oh! Very anxious

- Geotextile strong indicators of the interpolation method: For example: geotextile 150 grams of breaking strength is 4.5KN, geotextile 100 grams of breaking strength is 2.5KN, then the geotextile 130 grams of broken strength is how much? The calculation method is: 4.5KN-2.5KN = 2KN (that is, 50 grams of geotextile strength) 2KN by 50 grams multiplied by 30 grams is equal to 1.2KN then geotextile 130 grams of breaking strength is 3.7KN.

- Q: How about the geotextile pond

- You said to cover the fish pond, I understand is to build the bottom of the fish pond, but the use is not geotextile, but the composite geomembrane, the film is generally two layers of geotextile in the middle of a layer of geomembrane, , And geomembrane on both sides of the geotextile can prevent the bottom of the sharp objects pierced the geomembrane.

Send your message to us

Geotextile Nptel White Isolation Non-Woven Geotextile Fabric for Road, Custom Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords