Geotextile Coir Isolation Non Woven Geotextile Fabric for Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Description:

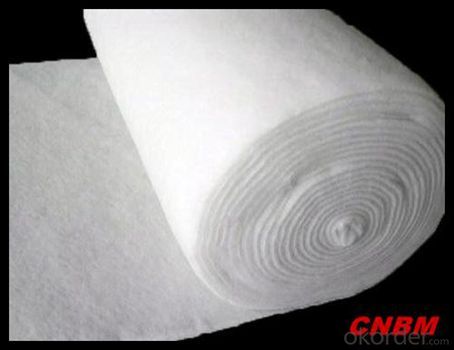

Non-woven Geotextiles (polyester geotextile, non-woven geotextile) is also called the geotextile, it is permeable geosynthetic materials composed of synthetic fiber by acupuncture or woven. Finished cloth, general width of 4-6 meters, 50-100 meters in length. The geotextile is divided into nonwoven geotextiles and geotextile. Geotextile has excellent filtering, isolation, reinforced protective effect, high tensile strength, good permeability, high temperature resistant, anti freeze, aging resistance, corrosion resistance.

Applications:

1, storage, transportation and treatment of geotextiles: geotextile volume in the installation of expansion to avoid damage. The geotextile volume should be stacked to not water the smooth place, high stack of not more than four volumes of height, and can see the identification sheet volume. The geotextile volume must be opaque material covered to prevent ultraviolet radiation aging. During storage, to maintain the integrity and the integrity of information label. In the process of transportation (including a scene from the material storage to the work of the transport), geotextile volume must avoid damage. By physical damage to the geotextile volume must repair. The geotextile can't wear use. Any contact to the leakage of chemical reagents geotextile, are not allowed to use in the engineering.

Methods 2, laying Geotextile

2.1 artificial rolling shop; surface should be smooth, and keeping proper deformation allowance.

2.2 filament or staple geotextile installation welding methods, usually with overlapping suture and. Suture and weld width is generally more than 0.1M, lap width is generally more than 0.2M. Possible long-term exposure of geotextile, shall be welded or suture.

2.3 geotextile suture: all suture must be continuous (e.g., crack is not allowed). In the overlap, geotextile must overlap at least 150mm. Minimum needle distance selvage (material exposed edge) is at least 25mm.

Sewing geotextile joint best consists of 1 lines and line lock chain stitch. Suture line should be used for resin material as the minimum tension over 60N, and with geotextile or beyond the resistance to chemical corrosion and UV resistance. Any sewn on the geotextile "skip" must be affected to seam. We must take corresponding measures to avoid after installation, soil, particulate matter or foreign substances into the geotextile layer. Cloth lap according to the terrain and the use function can be divided into natural overlap, or welding seam.

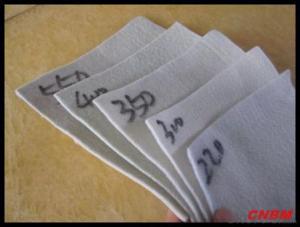

Specifications:

1 grams of weight range: 10 ~ 250g/ square meters;

2 the maximum width: 1.6 meters (according to the customer request length processing)

3 color: can be produced according to customer requirements

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: What are the main functions of geotextiles?

- The main functions of geotextiles include providing separation, filtration, reinforcement, and drainage in various civil engineering and construction applications.

- Q: After the laying of drainage board and then need to lay a layer of geotextile it?

- After the laying of drainage board and then need to lay a layer of geotextile it?

- Q: Can geotextiles be used in drainage applications?

- Yes, geotextiles can be used in drainage applications. They are commonly used to enhance the performance of drainage systems by providing filtration, separation, and reinforcement. Geotextiles can help prevent soil erosion, control sediment, and improve water flow, making them suitable for various drainage applications such as retaining walls, roadways, and agricultural fields.

- Q: What are the different geotextile installation techniques for erosion control blankets?

- There are several geotextile installation techniques for erosion control blankets, including trench and backfill, stake and tension, and anchor and pin. Trench and backfill involves digging a trench along the slope, placing the erosion control blanket in the trench, and then backfilling it with soil. Stake and tension involves driving stakes into the ground at regular intervals and then securing the erosion control blanket to the stakes with tensioning devices. Anchor and pin involves using anchors or pins to secure the erosion control blanket directly to the ground. The specific technique used depends on the slope conditions and project requirements.

- Q: Can geotextiles be used for reinforcement of railway embankments?

- Yes, geotextiles can be used for reinforcement of railway embankments. Geotextiles are commonly used in civil engineering projects for their ability to provide separation, filtration, and reinforcement functions. When used in railway embankments, geotextiles help improve the stability and strength of the embankment by preventing the mixing of different soil layers, reducing soil erosion, and distributing load more evenly. Overall, geotextiles are an effective solution for reinforcing railway embankments and enhancing their long-term performance.

- Q: Are geotextiles effective in preventing weed growth?

- Yes, geotextiles are effective in preventing weed growth. They act as a physical barrier that inhibits weed growth by blocking sunlight and preventing weed seeds from germinating. Additionally, geotextiles allow for water and air permeability, ensuring proper drainage while still suppressing weed growth.

- Q: Reservoir dam waterproof geotextile cloth two bags of a large package should be how much money

- Do not understand, to answer what is the problem with ah, Google then you deleted, Google know the system do not know how ah

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a physical barrier that prevents soil erosion and the displacement of soil particles. They provide support to the soil, distribute load stresses, and improve the overall stability of the ground. Additionally, geotextiles promote water drainage and filtration while preventing the loss of fine soil particles, thereby enhancing soil quality and preventing erosion-induced damage.

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve slope stability by providing reinforcement and erosion control. They are placed within the slope to act as a barrier against soil movement, preventing erosion and enhancing the overall stability of the slope. Additionally, geotextiles help to distribute loads more evenly, reducing the potential for slope failure.

- Q: What is the price per square of the non-woven polyester fabric? What is the difference between the geotextile used in the building?

- About two more money it! You can search Yuan Shuqing look! Have to sell! Quite cheap!

Send your message to us

Geotextile Coir Isolation Non Woven Geotextile Fabric for Road

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords