White Non Woven Geotextile Fabric used in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Property:

1.High strength ; low deformation.

2. Durability: steady property, not easy to resolved, airslaked and keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resist insects and mould.

4. Permeability: the woven geotextile can control the sieve size to retain permeability.

It is widely used in river , coast ,harbour, highway ,railway, wharf, tunnel, bridge and other geotechnical engineering. The woven geotextile is a invaluable product and can be separation, reinforcement , protection and other.

Width <=6.0m, length: 50(at request)

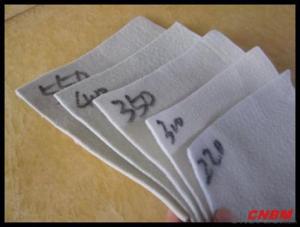

Geotextile Specifications

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

4.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

5.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

6.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

7.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Roof garden pool at the bottom with pebbles, pebbles above with geotextile, geotextile above the soil

- Geotextile laying on the soil can be, goose soft stone has replaced the effectiveness of the drainage board. Geotextile play a filtering effect, the excess water through the cloth, go through goose soft stone flow. Soil is geotextile interception, will not be lost, plug the drain, Huazhi geotextile material manufacturers.

- Q: Non-woven fabrics, geotextiles and geotextile geotextile

- The same material that I specialize in producing

- Q: Related applications, product applications, industrial structure and distribution

- The geotextile is defined as geotextiles or geosynthetics that exist between soils and pipelines, gages, or retaining walls, that enhance water movement and impede soil movement. ASTM 4439 standard geotextile is defined as: a purely permeable geosynthetics to form textiles. It is used in soil, rock, soil, or other geotechnical engineering materials and acts as a component of a human-made project. It is a permeable geosynthetics made of synthetic fibers by needling or weaving. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. I also check in the road cloth, just to find, you should be a peer to share with you

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include understanding the slope stability and soil characteristics, selecting the appropriate type and strength of geotextile, ensuring proper anchoring and connection methods, implementing effective drainage systems, and regularly monitoring and maintaining the geotextile system.

- Q: Can geotextiles be used in underground storage tank installations?

- Yes, geotextiles can be used in underground storage tank installations. Geotextiles are often used as a protective barrier between the tank and the surrounding soil to prevent contamination and provide stability.

- Q: What are the different geotextile testing parameters?

- Some different geotextile testing parameters include tensile strength, puncture resistance, burst strength, permittivity, apparent opening size, and UV resistance.

- Q: What is the price of composite geotextile?

- Geotextile is divided into polyester short geotextile, staple acupuncture geotextile, polyester filament geotextile, woven geotextile, filament woven geotextile, and so on. Specifications and different models, the price is also different, composite geotextile weight in the 80-1500g / ㎡ between the quality standards are divided into non-standard, whitening A, Sinochem, the general national standard and so on. The t value is generally between 4900 and 7500 yuan / ton, 187 & lt; 6600 & lt; 5604

- Q: GB / T geotextile sampling sampling frequency, 100 volumes equal to the number of square meters?

- Geotextile wide conventional is 6 meters, there are also more narrow and narrow, the length of conventional 50 meters or 100 meters, if the conventional calculation of a roll is 300 square meters or 600 square meters, 100 volumes will be multiplied by 100 on the line The

- Q: How do geotextiles help in reducing the settlement of structures on soft soils?

- Geotextiles help in reducing the settlement of structures on soft soils by providing a stable and reinforced foundation. They act as a barrier between the soil layers, distributing the load evenly and preventing excessive settlement. Additionally, geotextiles improve the soil's drainage and filtration capabilities, allowing water to permeate and preventing waterlogging, which can further contribute to settlement.

- Q: How to calculate the volume weight of polypropylene nonwoven geotextile

- I professional production geotextile geomembrane and other materials, wish smooth

Send your message to us

White Non Woven Geotextile Fabric used in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords