Wellhead Assembly of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Wellhead Assembly Description

The gas production wellhead assembly is designed and manufactured in accordance with GB/T22513-2008 and API Spec 6A standards.All pressure-bearing parts and flanges are forge pieces of high-grade alloy steel and stainless steel and subjected to non-destructive test(NDT) and special heat treatment to insure safety and good sulphur-resisting performance.

This product consists of such components or parts as bottom flange,top flange,tubing head,gate valves,small-sized four-way union,stop valves and measuring instruments,etc.

2. Main Features of Wellhead Assembly

Working Pressure: 2000-20000psi

Working Temperature: PU Material Class: AA-FF

Available Medium: Crude Oil, Water, Gas

Connection Type: Clamp, Flanged

PR: PR1-2

PSL: PSL1-3

Normal Size: Main (in): 2-9/16, 3-1/8, 3-1/16

Side (in): 2-9/16

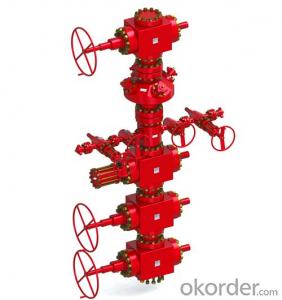

3. Wellhead Assembly Images

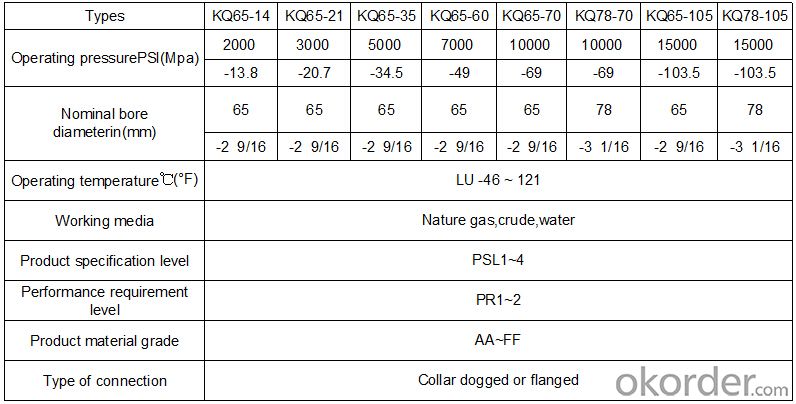

4. Wellhead Assembly Specification

5. FAQ of Wellhead Assembly

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I have my head off now I need to change my valves how do I do it?

- What I would do is just take the heads to an automotive machine shop and have a valve job done on them. They will do everything, grind and resurface the head and valve seats. This is the smart way to DIY. Do what you can do well yourself and let those with the proper tools training and expertise do what they do best. You'll save money this way and get the best work done at the best price.

- Q: I don't have one single water shutoff valve in my house that will shut anything off completely. It looks fairly easy to repack them, and I have the tools, and there are instructions all over the internet. The question I have for the experienced among you is what packing material do I use? I have heard graphite thread and teflon tape and even joint compound.Is one better than the other? Easier to use?Also, if there are any pitfalls I should know about before I undertake this, please advise.Thanks in advance!

- Well if you talking about the water shutoff valves under sinks then you need to first shut off the water comming into the house at the main shutoff valve near the street , Or at a line comming into the house that connects up to the valve you are trying to fix or you may take a slight bath while trying to fix the valve that wont shutoff. Then Go to the shutoff valve you want to repair in that line where you shut the water off at and unsrew the handle at the base of the handle shaft using two wrenchs to hold both the nut on the shaft while using the other to hold the shutoff valve .this will prevent twisting the valve right off the connecting lines. Most of the time you will find it has a rubber gromet attached by a screw to the handle shaft.this is what you need to replace with a new rubber gromet which you can get in an assortment box at wal mart or homedepot or lowes for a low price. If you are using teflon thread or jointcompound you are repairing a Pipe joint leak where water is leaking externally of the pipe,not a shutoff valve leak .

- Q: If my understanding is correct, in a standard combustion engine as you press the gas pedal the speed of everything increases: the cam shafts spin faster (and thus the valves move faster), the pistons move faster...EVERYTHING goes faster. That sounds like an optimal system in theory, so what is the benefit of having the valves be able to be intelligently out of phase (for lack of a better phrase) with the rest of the system?

- Thinking of time, the valves are open longer during engine idle and much less at higher engine speeds. Now think of a small block chevy where we can change engine timing a little bit advanced or retard which affects power and performance. To make a bigger change, another grind of camshaft has to be installed. This grinding of camshaft is called profile - the characteristics of the lobes size, ramps and direction which work at an entirely different fashion. With variable valve timing, the computer can advance or retard a cam to adapt to many different profiles to provide the best power, torque, economy and lowest emissions possible for any given condition such as cruising down a highway, climbing a long tall hill, or driving light to light through the city. Almost an infinite amount of profiles without swapping out a single camshaft. Seems alot easier and sure is alot cheaper, and we don't have to do the work anymore. Systems are pretty reliable as they typically use engine oil pressure that is directed by a solenoid run the by the ECM on a duty cycle which allows oil pressure to the advance side of a cylinder on the end of a camshaft where the cam is rotated ahead of its resting position thus changing the time the valves are open and when they open. The cam is spring returned to resting position ( some may be hydraulic?) Hope I explained this so it is clearer than mud.

- Q: Can someone explain to me what lead and lag time are? Also, what are the three flow characteristics? Linear, equal percentage but what is the third. If I wanted to have a minimum stop at 25% on a non-linear valve such as a butterfly valve, how would I achieve this. Obviously you cannot just restrict the valve by 25% of its travel as it is not linear

- Hope this helps in some way... To start the 3 main flow characteristics of a control valve are Liner, Equal percentage and Quick opening (or fast opening). If you interested there are also other characteristics. As far as i am aware the lead time is the time in which a signal is sent to the valve and the lag time is the time in which the actuator moves and closes the valve. The pysical movement. As for your final question the only thing i can think of is to alter the actual size of the butterfly valve or put a reducer before it. Sorry if my information was of little use.

- Q: I just found out about my condition. Is it dangerous? And will I need surgery? My mom just got her monocuspid valve replaced. I don't wanna have to go through the same thing. And will I still be able to go on rollercoasters? I'm going to cedar point tomorrow. I only want answers from people who know exactly what there talking about thanks

- so, as you already know, a typical aortic valve has three cusps. yours has two, so this is a structural issue. the point of these cusps, or leaflets, is to maintain blood flow in the appropriate direction through the heart and to the rest of the body. having a bicuspid aortic valve can be something that you inherit from one of your parents. did you have a murmur that prompted them to look for it? if your valves are young and healthy, there's probably not a problem. when it can become problematic is with age, where the leaflets can become calcified and hard, then they can not open as well (i.e. become stenotic), or not close properly (i.e. become regurgitant). if either of these two things develops, and becomes bad enough, they consider valve replacement surgery. but this is the kind of stuff that happens over years and years. you should see a cardiologist, if you haven't already been referred to one, because this is a medical condition that gets watched over time, and then if it gets bad, it gets treated. while it's not bad, it gets watched. this cardiologist will follow you over time, in addition to your regular family physician. he/she will also be keeping an eye on your aorta (the big vessel that blood enters after it goes through the aortic valve), because sometimes people who have bicuspid aortic valves also have problems with your aorta. i would also talk to your cardiologist about whether or not you need to take antibiotics in advance (i.e. prophylactically) of any dental work. i.e. because of your valve with a different shape, are you more predisposed than the average person to getting an infection there. but go to cedar point if you're young and healthy. a roller coaster should not give you any sort of problems. enjoy yourself!

- Q: Is it possible that if you never adjust valves the engine could lose a lot of compression? 1990 Suzuki VX800, 19,000 miles on the clock. No idea if it has ever had the valves adjusted, only got it 3,000 miles and 6 months ago. It is now not running and after a compression test, has 90 psi in the rear and 150 psi in the front cylinder. Don't really have the time yet for a leak down test. Could the exhaust valves be the cause of the low compression? thanks.

- Yes it can lose compression if your valve lash is too tight. This can also cause the valves to burn. Adjust your valves as soon as you can.

- Q: I have a 3-circuit sprinkler system in my yard (built by me, last year). I discovered this week that I overtightened the connection between the valves and the downstream pipes, and 2 of the three valves are cracked, and leaking, at the connection. I replaced all 3 valves, and now I need to reconnect them to the supply. But this means I'm working backward - when I bult the system last year, I worked downstream - I built the manifold first, connected the valves, then the remainder of each branch. Now, I have to make the new manifold fit the valves, and naturally, they don't line up perfectly. Any tips/tricks on connecting valves in this situation? Is there such a thing as flexible pipe that can withstand continuous pressure? I'm using unions at both ends of each valve to help things go together/come apart more easily.

- valve manifolds are something that requires practice and experience. i used to struggle with them at work until i did a good bit of them. 3 zones is not that many valves so it shouldnt be too difficult. if they wont line up exactly right, i would recommend adding longer peices of pipe to the mainline side of the vavles and re routing the supply line futher back and you will have more room to flex the pipe and vavles into the Tees and 90s. do not use any form of flexible pipe on any mainline. you will regret it. lol the bigger the hole you dig will give you the most room and the more pipe, and room will give you more flexability to build the manifold. it is easier to connect the valves the way you did it first though, but you can do it either way. good luck and hope this helps

- Q: If I flush the toilet the drama begins. While the toilet is flushing, if I lift the lift of the lid of the tank cover NOT THE SEAT, water shoots up straight in the air from the top/cap of the fill valve. This is a picture of a toilet fill valve.

- If you had proper plumbing this would not happen. Have a look at an Armitage Shanks catalogue..............oh sorry, you are in the US arent you....... o well

- Q: I went to turn the water off with the shut-off valve so that I could do some work on the toilet tank (replacing old and leaky fill valve) but the water won't shut off. I'm assuming that I'll need to replace the shut-off valve itself but could anything else be causing the problem? The funny thing is, the leaky fill valve that I wanted to replace has now stopped hissing and leaking and the tank seemingly fills fine. But of course the water can't be turned off completely.Just wanted to check make sure that there aren't anything else I should do or consider before I went off to replace the shut-off valve.Thanks

- If you are turning on that valve and it doesn't shut off the flow of water to the toilet, then the valve should be replaced. Now, if it's not leaking, you don't HAVE to replace the valve. But of course, if the toilet overflowed you wouldn't have any easy way of shutting off the water There are many, many choices in replacing valves. You have to determine which kind of valve you have - sweat on, male or female thread, or compression - size of pipe coming out of the wall - size of thread for the fill tube. Once you have that figured out, you do need to turn off the house water before you take the old valve off. One more choice: Spend the extra couple of bucks and get a 1/4 turn ball type valve.

- Q: the ac replacement valve seems to be leaking i was wondering what is the average cost of having it replaced..

- The ac replacement valve? Well, what you can do is to get the new ac to replace the old ac.

Send your message to us

Wellhead Assembly of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords