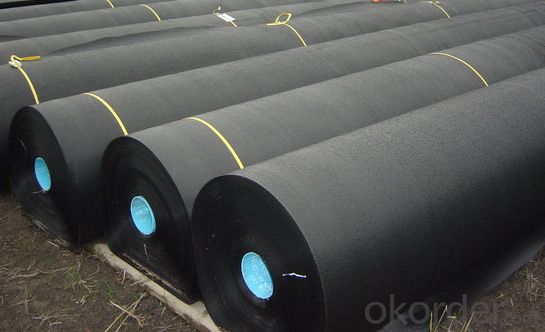

2mm Waterproof Geo Membrane with Geotextile for Retaining Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product description

A geomembrane is very low permeability synthetic membrane liner or barrier used with any geotechnical engineering related material so as to control fluid (or gas) migration in a human-made project, structure, or system. Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer sprays, or as multilayered bitumen geocomposites. Continuous polymer sheet geomembranes are, by far, the most common.

Applicaion

Flood control, Irrigation

Waterproofing Dams

Waste management: Landfill

Municipal Solid Waste

Wastewater Containment

Anaerobic Lagoon Cover Systems

Lagoon Liner Systems

Tunnel

We can produce following clients' requirements, for further information, please contact us.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Principle of drainage pipe geotextile

- Principle of drainage pipe geotextile

- Q: How do geotextiles help with weed control in landscaping projects?

- Geotextiles help with weed control in landscaping projects by acting as a barrier that prevents weed growth. They are placed under the topsoil or mulch and effectively block the sunlight that weeds need to grow. Additionally, geotextiles provide a physical barrier that inhibits weed root penetration and spread. This reduces the need for chemical herbicides and minimizes the maintenance required to keep landscaping areas weed-free.

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. Well, long-term perspective, then we must do a solid job every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem, this is the status of China's construction industry. But the debt owed sooner or later.

- Q: Can geotextiles be used in wastewater treatment systems?

- Yes, geotextiles can be used in wastewater treatment systems. They are commonly used in various stages of the treatment process, such as filtration, separation, and dewatering. Geotextiles can help in removing solid particles, preventing clogging, enhancing filtration efficiency, and providing structural support to the system.

- Q: What are the maintenance requirements for geotextile-reinforced retaining walls?

- The maintenance requirements for geotextile-reinforced retaining walls typically include regular inspections for signs of erosion, damage, or structural issues. Additionally, any vegetation growing near the wall should be monitored and removed if it poses a threat to the integrity of the structure. It is also important to ensure proper drainage and prevent water buildup behind the wall. Regular cleaning and removal of debris is necessary to avoid blockages and maintain the functionality of the drainage system. Overall, following manufacturer guidelines and conducting routine maintenance activities will help ensure the longevity and effectiveness of geotextile-reinforced retaining walls.

- Q: The secondary lining of the tunnel to install the vertical ring to the blind tube hang the geotextile waterproof board generally used for how long

- See the progress of the project

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by acting as a physical barrier that prevents soil erosion and the displacement of soil particles. They provide support to the soil, distribute load stresses, and improve the overall stability of the ground. Additionally, geotextiles promote water drainage and filtration while preventing the loss of fine soil particles, thereby enhancing soil quality and preventing erosion-induced damage.

- Q: How do geotextiles help with moisture management in construction projects?

- Geotextiles play a crucial role in moisture management in construction projects by acting as a barrier against water infiltration, allowing excess water to drain away while retaining sufficient moisture for the construction materials.

- Q: Do geotextiles require regular maintenance?

- Yes, geotextiles generally require regular maintenance to ensure their effectiveness and longevity. This may include inspecting for any damage or wear, removing any debris or vegetation that may accumulate on the surface, and addressing any soil erosion or drainage issues that may arise. Regular maintenance helps to preserve the integrity and functionality of geotextiles in various applications such as erosion control, filtration, and stabilization.

- Q: Do you want to put the geotextile and the impounded vegetables in the soil?

- No poison, you can rest assured that use. Geotextile raw materials are PET or PP, and the production of mineral water bottles of raw materials the same, without any side effects. Water storage board is the raw material is HDPE plastic. There is no harm to people. Geotextile and water storage board is mainly used in the roof garden or underground garage roof green. It is possible to store rainwater and protect the concrete at constant temperature. , Has been widely used in developed countries. At present the country is developing urban sponge project, the application of water storage board will be more extensive.

Send your message to us

2mm Waterproof Geo Membrane with Geotextile for Retaining Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords