Waterproof Coating For Roof Single Component Polyurethane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

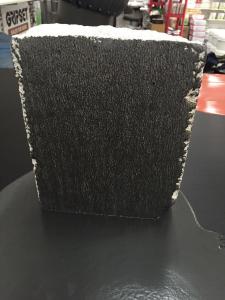

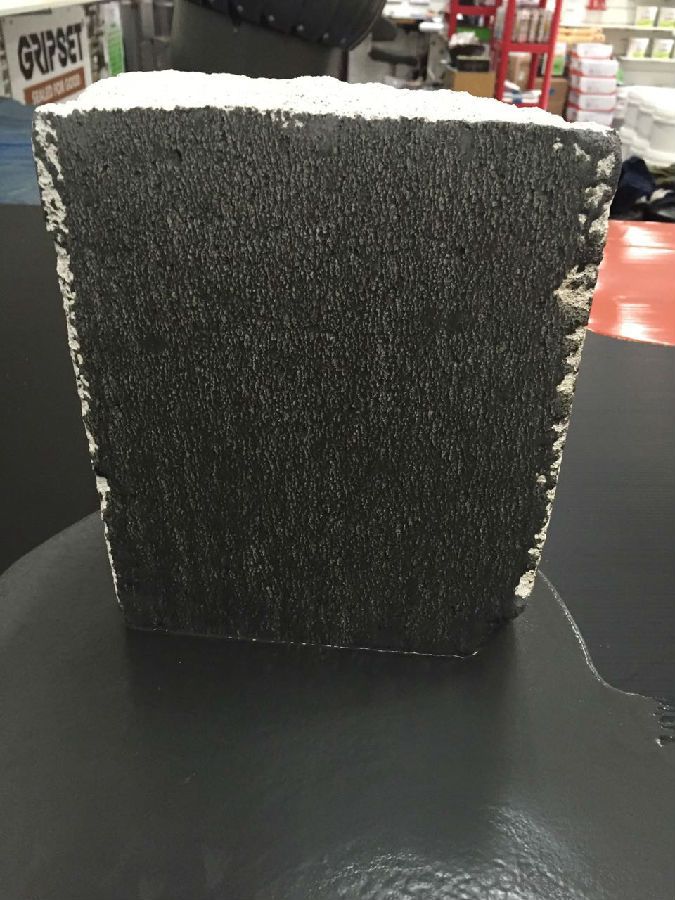

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Waterproof mortar expensive or dry mortar expensive

- Waterproof mortar more expensive. Because waterproof mortar compared to dry mortar, to add another waterproofing agent, emulsifier and other substances. Waterproof mortar regardless of the cost or transport are more cost-effective.

- Q: What material is used for waterproofing of tarpaulin

- Cement-based waterproof paste (such as the Swiss Sika) Product category Cement-based materials non-toxic, environmentally friendly, both in the construction process also Is formed after the harmless to humans and animals.

- Q: How do you make waterproofing in the kitchen and bathroom?

- Fatty acid cement mortar waterproofing agent; integrated current domestic and foreign new waterproof material of the latest technology, in the original polymer cement mortar waterproofing agent developed on the basis of raw materials imported from Germany, the higher fatty acid materials, by more than 20 kinds of raw materials by the special complex Chemical reaction of water-based emulsion, a new type of fatty acid cement mortar waterproofing agent.

- Q: What material waterproofing can be mixed with cement sand

- Construction can also be used to produce waterproof pulp, waterproofing agent for the amount of cement 3 ‰ -4 ‰, the use of cement label not less than 32.5MPa.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Of course harmful, not just this particle, there are auxiliary materials are also toxic.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- As the SBS coil finished with pure asphalt is not the same, the coil includes a variety of surface material weight. The following is the different types and different thickness of the SBS coil unit area weight, due to the need to lap and pave the reinforcement layer, calculate the load in the following unit area weight, the general multiplied by 1.2 coefficient.

- Q: What are the key points and contents of the quality control of waterproof material?

- 4, high-polymer modified asphalt waterproofing membrane: check the counterfeit effective and simple method is to cut the film wrapped down and then placed in the refrigerator freezer placed 3 hours after the removal, gently forced to break will be broken, and the national standard Require material low temperature flexibility to reach -20 ℃.

- Q: Villa roof leakage what general reasons, what materials to remedy

- Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q: Waterproof material water leakage construction should pay attention to what

- 2, wall treatment · Wall treatment to do about 300mm high waterproof coating, to prevent water infiltration wall back tide. · Bathroom between the wall and the ground (plane and elevation) brushing height should be greater than 100mm. · The height of the shower room in the bathroom is not less than 1800mm. · If there is a bathtub, the height of the wall adjacent to the bathtub should be 300mm higher than that of the bathtub. · Waterproof height of tub is not less than 800mm. · The height of the squat should be more than 900mm. For the transformation of the toilet wall and self-built light wall, the proposed height of the waterproof to do the top.

Send your message to us

Waterproof Coating For Roof Single Component Polyurethane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords