Single Component Polyurethane Waterproofing Coating For Steel Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

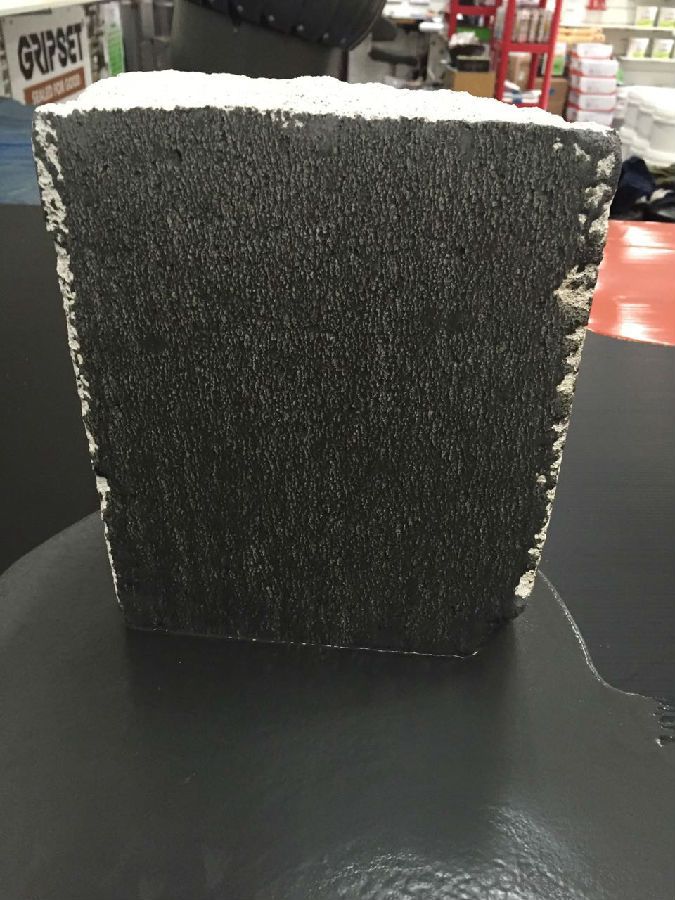

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: A complete set of basement waterproof construction program

- 2.2 site preparation 2.2.1 external wall of the pull bolts should be cut off in advance, wooden blocks removed after the use of cement mortar smooth. 2.2.2 grass-roots should be clean, concrete joints processing flat, made at the corner of the yin and yang ...

- Q: Can acrylic materials be perforated? How to do waterproof after punching?

- Or in the back with glass adhesive paste anti-corrosion nine PCT board (if the hole is flat, Anti-corrosion nine PCT is to remove the other side of the paste surface with asphalt anti-corrosion paint brush)

- Q: Waterproof mortar expensive or dry mortar expensive

- Dry mortar is usually called hydraulic cement mixed mortar, refers to the dry sieve treatment of aggregate (such as quartz sand), inorganic cementing materials (such as cement) and additives (such as polymers) and so on a certain proportion of physical mixing Into a granular or powdered, in the form of bags or bulk transported to the site, add water, mix directly after the use of materials.

- Q: Home improvement waterproofing problem

- 1, you said the above three products are old products. It is recommended to use the latest dosage form of cf-2000 efficient composite waterproofing agent, is the latest cement-based crystalline products. Not only then to solve the leakage problem, and the composite waterproof agent in the active material in the water or moisture under the action, but also continue to penetrate into the concrete layer. The formation of 10 cm from the self-waterproof layer. If the self-waterproof layer due to external factors caused by small cracking, as long as there is water through, you can start the active substance of the secondary repair function, to automatically repair the crack water seepage.

- Q: How do you make waterproofing in the kitchen and bathroom?

- Fatty acid cement mortar waterproofing agent; integrated current domestic and foreign new waterproof material of the latest technology, in the original polymer cement mortar waterproofing agent developed on the basis of raw materials imported from Germany, the higher fatty acid materials, by more than 20 kinds of raw materials by the special complex Chemical reaction of water-based emulsion, a new type of fatty acid cement mortar waterproofing agent.

- Q: What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Your pores, the respiratory tract, the lungs, will be hurt, when young do not feel out, the consequences more powerful than smoking.

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Third, from the indoor water leakage area for waterproof maintenance.

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Construction of roof waterproofing membrane First, the process (hot melt construction) Clean up the grass-roots → brushing the primary treatment agent → paving the film additional layer → paving the film → hot melt sealing side → water test → protective layer

- Q: How can the toilet waterproof works fail?

- After the failure of the bathroom waterproofing project to solve the specific needs of the specific analysis of targeted treatment. ??????? Bathroom waterproof is the problem more decoration works. The main reasons are: 1, construction (local, details, etc.); 2, waterproof material problems; 3, the structure (such as uneven settlement, cracking, etc.); 4, to save a little waterproof waterproof measures. ???????? After the three must be redo waterproof, the first type of reasons can be used to the appropriate remedial measures, pay the table "bathroom waterproof failure part of the phenomenon and the remedy list." ??????? Please responsible professionals in the field to carefully check the judge to find specific reasons for dealing with the need to destroy the red or must be destroyed, do not affect others after causing greater losses. The following are the same as the "

Send your message to us

Single Component Polyurethane Waterproofing Coating For Steel Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords